Novel monocrystalline silicon cutting platform

A cutting platform and monocrystalline silicon technology, which is applied to fine working devices, working accessories, manufacturing tools, etc., can solve the problems of electromagnetic attraction and valve seat instability, electromagnetic attraction and components occupying a large space and volume, and achieve reduction effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

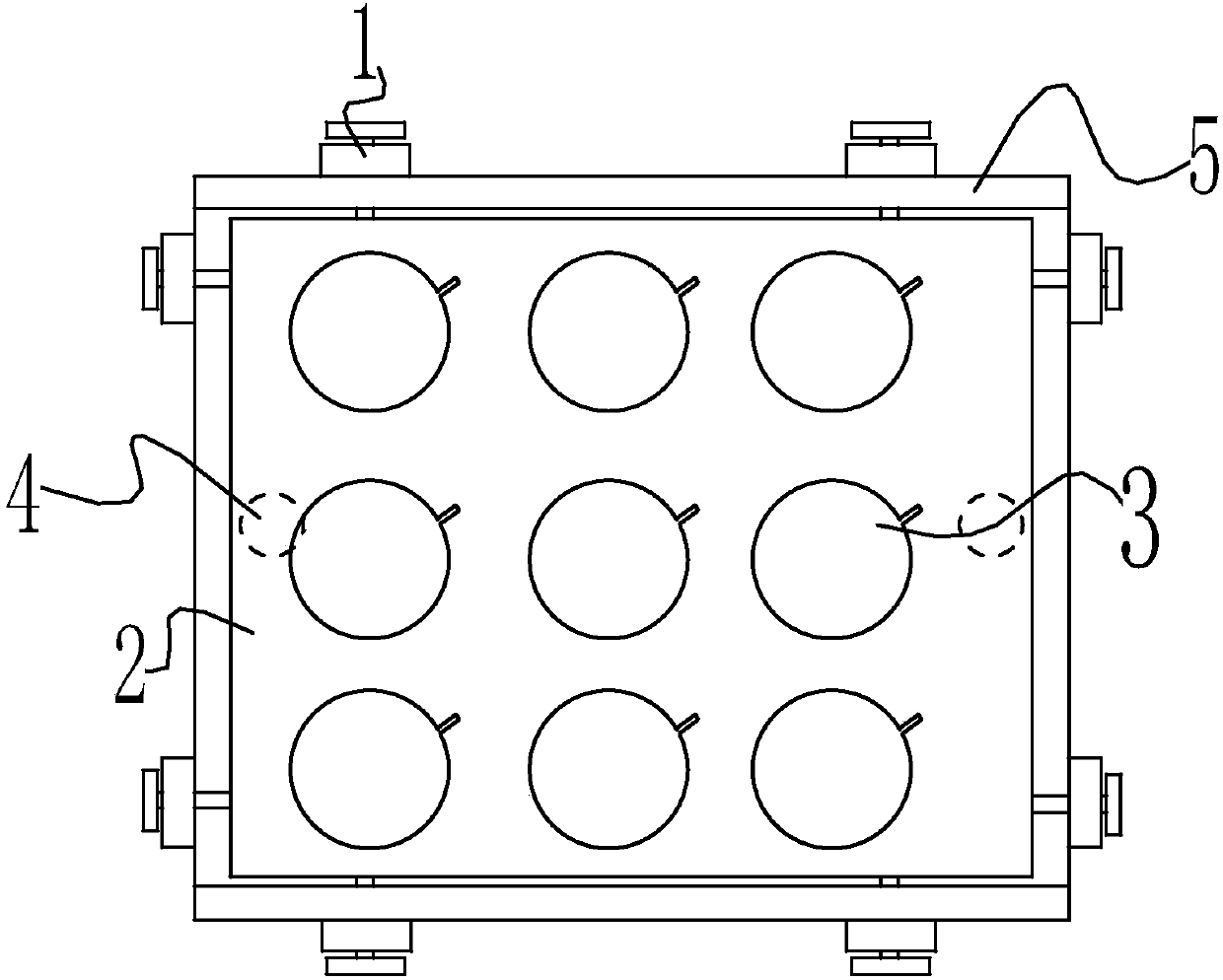

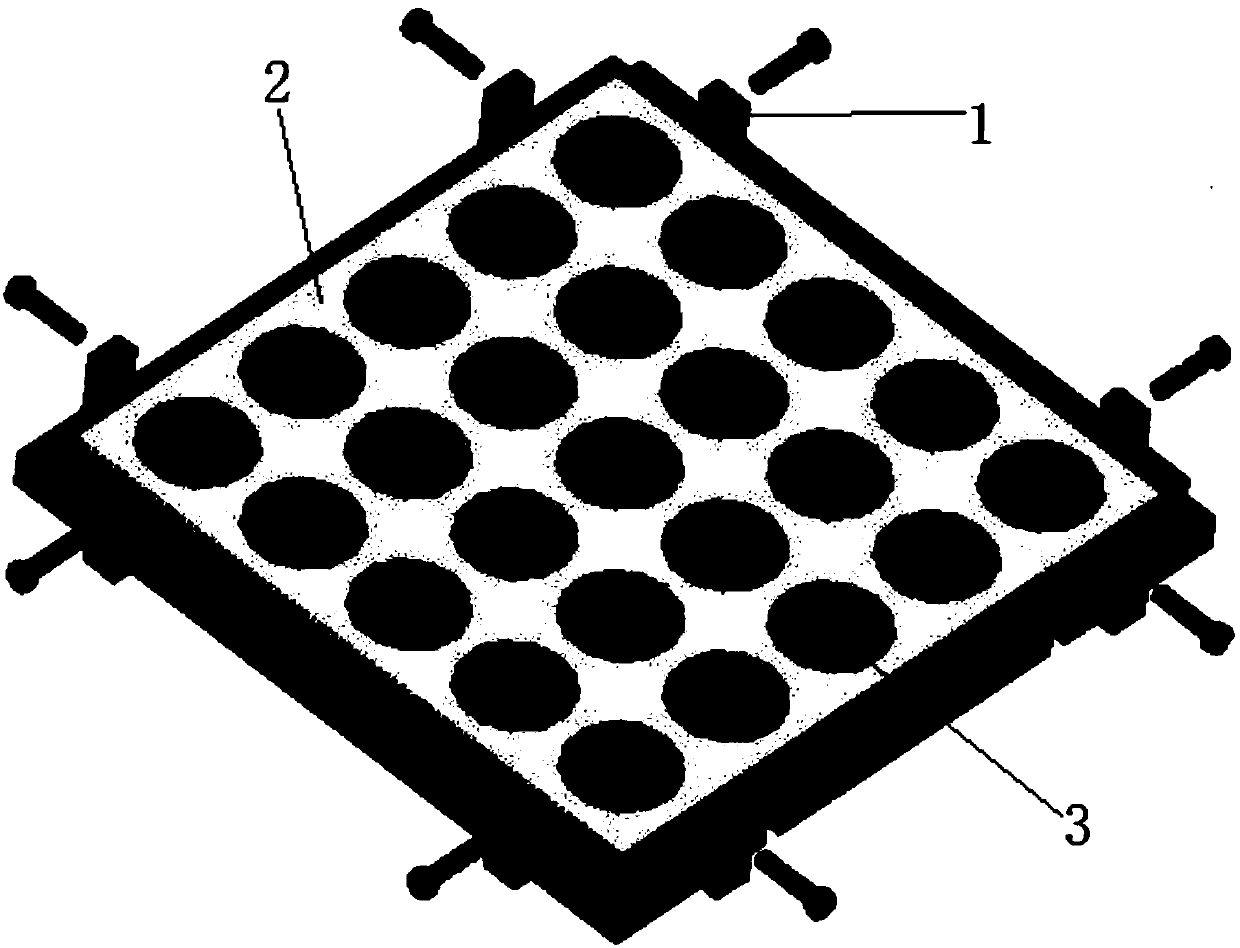

[0017] The following is attached Figure 1-2 The present invention is described in further detail.

[0018] A new type of monocrystalline silicon cutting platform, which includes a carrying platform, the carrying platform is a square platform, and guide edges 5 are symmetrically arranged on both sides of the carrying platform, and a sliding support is provided on the carrying platform between the guiding edges Platform 2, the sliding platform is a flat platform body, the sliding platform is just fitted between the two guide edges, and the sliding platform and the guide edges cooperate with each other to maintain free sliding ability.

[0019] The upper surface of the sliding platform is provided with a plurality of crystal holder grooves 3 for fixing and matching with the crystal holder.

[0020] There are two vertical blocks 1 on the four end faces of the supporting platform corresponding to the four sides of the sliding platform, and each vertical block is screwed with a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com