High-pressure atomization method for preparing graphene dispersion and its polymerization method for preparing graphene nylon

A graphene dispersion, high-pressure atomization technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems that the performance of graphene nylon cannot reach the ideal state, no graphene is reflected, and it is difficult to disperse, and the number of layers can be reached. Less, better dispersion effect, lower requirement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

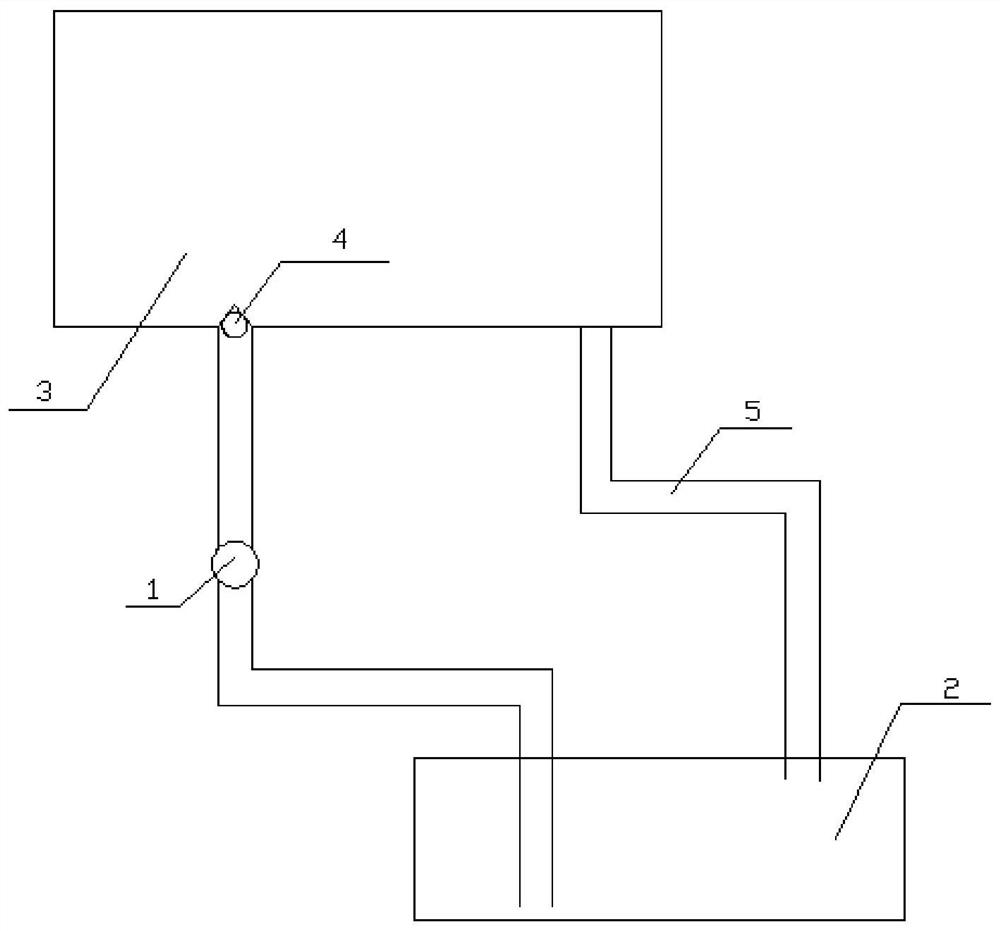

[0028] The preparation of the graphene dispersion liquid of the present invention comprises the following steps: first calcining the graphite powder at a high temperature of 1550° C. to obtain the expanded graphite powder; then adding the above-mentioned expanded graphite powder into distilled water, fully stirring, That is to obtain the expanded graphite aqueous solution; and then through the ultra-high pressure pump 1 with a pressure of 150 MPa, the above-mentioned expanded graphite aqueous solution is atomized through the atomizing head 4 in a circular and sudden pressure reduction, and the graphene dispersion is obtained.

[0029] Further, the specific steps of the circulating and sudden pressure-reducing atomization are as follows: Utilize a 150MPa ultra-high pressure pump 1 to transport the above-mentioned expanded graphite aqueous solution in the reflux pool 2 to the atomization chamber 3 at a pressure of 1MPa. The atomizing head 4; the above-mentioned expanded graphite ...

Embodiment 2

[0035] The preparation of the graphene dispersion according to the present invention comprises the following steps: first calcining the graphite powder at a high temperature of 1650° C. to obtain the expanded graphite powder; then adding the above-mentioned expanded graphite powder into distilled water, fully stirring, That is to obtain the expanded graphite aqueous solution; and then through the ultra-high pressure pump 1 with a pressure of 170 MPa, the above-mentioned expanded graphite aqueous solution is atomized through the atomizing head 4 in a circular and sudden pressure reduction, and the graphene dispersion is obtained.

[0036] Further, the specific steps of the circulation type and sudden pressure-reducing atomization are as follows: Utilize a 170MPa ultra-high pressure pump 1 to transport the above-mentioned expanded graphite aqueous solution in the reflux pool 2 to the atomization chamber 3 at a pressure of 6MPa. The atomizing head 4; the above-mentioned expanded g...

Embodiment 3

[0042] The preparation of the graphene dispersion according to the present invention comprises the following steps: first calcining the graphite powder at a high temperature of 1850° C. to obtain the expanded graphite powder; then adding the above-mentioned expanded graphite powder into distilled water, fully stirring, That is to obtain the expanded graphite aqueous solution; and then through the ultra-high pressure pump 1 with a pressure of 200 MPa, the above-mentioned expanded graphite aqueous solution is atomized through the atomizing head 4 in a circular and sudden pressure reduction, and the graphene dispersion is obtained.

[0043] Further, the specific steps of the circulating and sudden pressure-reducing atomization are as follows: Utilize a 200MPa ultra-high pressure pump 1 to transport the above-mentioned expanded graphite aqueous solution in the reflux pool 2 to the atomization chamber 3 at a pressure of 10MPa. The atomizing head 4; the above-mentioned expanded graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com