A kind of preparation method of high-performance concrete waterproof material

A high-performance concrete and waterproof material technology, applied in the direction of flat products, non-polymer organic compound adhesives, other household appliances, etc., can solve the problem of inability to meet the requirements of the versatility of concrete waterproof materials, impermeability to improve the concrete structure Infiltration resistance, affecting the safety of concrete bridge decks, etc., to achieve the effects of tight bonding, increased thermal insulation performance, and long-term stable wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

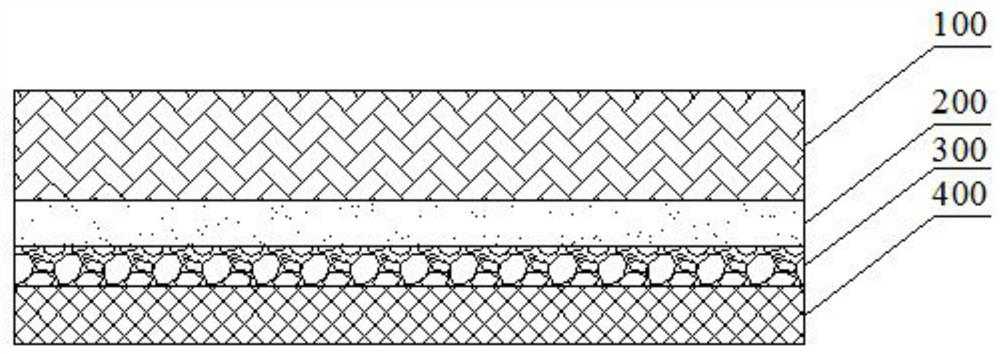

[0037] see Figure 1-2 As shown, the high-performance concrete waterproof material of this embodiment includes a wear-resistant waterproof layer 100 , an adhesive layer 200 , a release film layer 300 , and an anti-permeation crystalline layer 400 arranged in sequence from outside to inside. The release film layer adopts commercially available conventional PET release film.

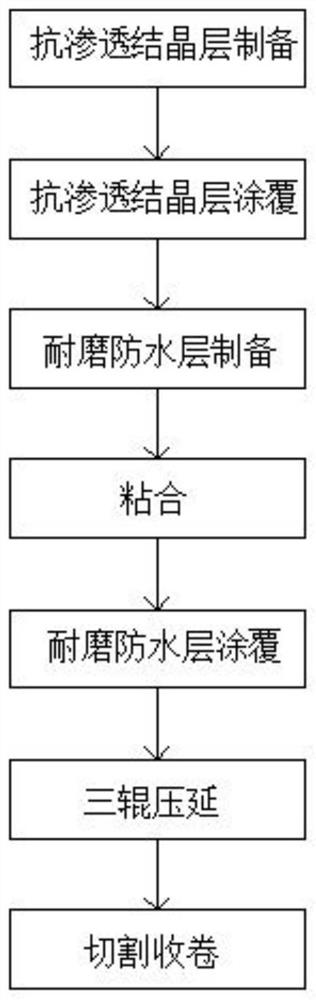

[0038] The preparation method of the concrete waterproof material comprises the following steps:

[0039] S1. Preparation of anti-permeation crystalline layer: In parts by weight, add 8 parts of graphene oxide to 52 parts of ultrapure water, stir with ultrasonic machinery for 42 minutes, then add 6 parts of silica airgel powder and 10 parts of potassium aluminum sulfate , 18 parts of attapulgite, after adding, stir evenly to form a viscous slurry, spray dry to obtain 200-300 μm anti-permeation crystalline masterbatch; add 32 parts of carboxylated styrene-butadiene rubber, 4 parts of woody Sodium sulfonat...

Embodiment 2

[0047] see Figure 1-2 As shown, the high-performance concrete waterproof material of this embodiment includes a wear-resistant waterproof layer 100 , an adhesive layer 200 , a release film layer 300 , and an anti-permeation crystalline layer 400 arranged in sequence from outside to inside.

[0048] The preparation method of the concrete waterproof material comprises the following steps:

[0049] S1. Preparation of the anti-permeation crystalline layer: according to parts by weight, add 9 parts of graphene oxide into 55% ultrapure water, stir with ultrasonic machinery for 37 minutes, add 7 parts of silica airgel powder, 9 parts of aluminum potassium sulfate, 20 parts of attapulgite, after adding, stir evenly to form a viscous slurry, spray dry to obtain 200-300 μm anti-permeation crystallization masterbatch; add 38 parts of carboxylated styrene-butadiene rubber and 5 parts of lignin to the anti-permeation crystallization masterbatch Sodium sulfonate, after mixing evenly, heat...

Embodiment 3

[0057] see Figure 1-2 As shown, the high-performance concrete waterproof material of this embodiment includes a wear-resistant waterproof layer 100 , an adhesive layer 200 , a release film layer 300 , and an anti-permeation crystalline layer 400 arranged in sequence from outside to inside.

[0058] The preparation method of the concrete waterproof material comprises the following steps:

[0059] S1. Preparation of the anti-permeation crystalline layer: in parts by weight, add 9 parts of graphene oxide into 47 parts of ultrapure water, stir with ultrasonic machinery for 45 minutes, then add 9 parts of silica airgel powder and 12 parts of potassium aluminum sulfate , 18 parts of attapulgite, after adding, stir evenly to form a viscous slurry, spray dry to obtain 200-300 μm anti-permeation crystal masterbatch; add 38 parts of carboxylated styrene-butadiene rubber, 5 parts of woody Sodium sulfonate, mixed evenly, heated up to 170°C, kept stirring for 1.5 hours, and obtained reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com