Lithium battery pole piece and preparation process thereof

A preparation process, lithium battery technology, applied in battery electrodes, electrode manufacturing, non-aqueous electrolyte battery electrodes, etc., can solve the problems of poor tensile toughness, easy to generate more dust, burrs or molten beads, etc., to improve the tensile strength Extensibility, not easy to burr, beneficial to the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] see Figure 4 , a lithium battery pole piece, comprising: a current collector and a coating layer;

[0060] The current collector further includes a support layer disposed between the current collector and the coating layer, and the support layer is at least one of a conductive carbon material and a metal material; wherein the conductive carbon material is selected from zero-dimensional conductive carbon, including acetylene black, conductive carbon black; one-dimensional conductive carbon, including carbon nanotubes; two-dimensional conductive carbon, including conductive graphite and graphene; three-dimensional conductive carbon, including at least one of reduced graphene oxide; metal materials selected from aluminum At least one of powder, iron powder and silver powder;

[0061] Further, the support layer is coated on the current collector to make a carbon-coated foil, and the support layer is preferably made of conductive carbon material, and the electron transmiss...

Embodiment 2

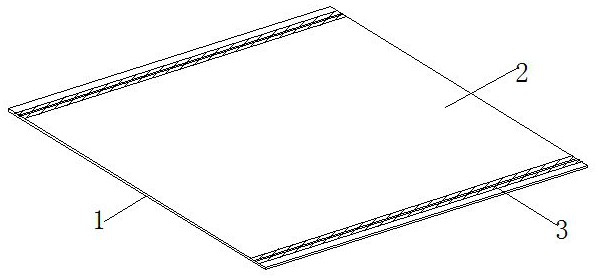

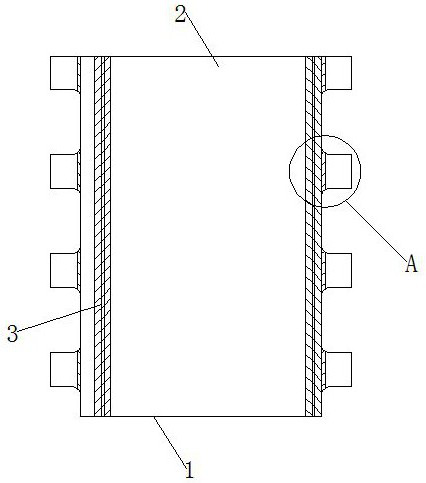

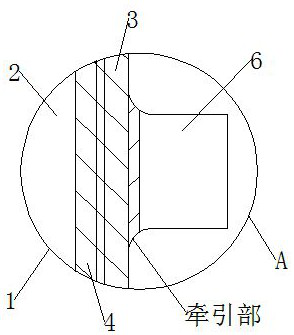

[0089] see Figure 1-Figure 6 , the current collector includes two layers of substrates arranged up and down and a layer of composite layer arranged between the substrates, and the composite layer is an interlayer between the two layers of the substrates, and the substrate and the composite layer pass through adhesive bonding;

[0090] Further, a plurality of through holes are formed on the surface of the current collector.

[0091] Still further, a welding point is arranged between the two layers of the base material, and the welding point is the edge of the through hole of one of the base materials;

[0092] The difference between this embodiment and Embodiment 1 is that the current collector used in the above Embodiment 1 is a carbon-coated foil, while this embodiment provides a composite foil, and the specific preparation method of the composite foil is as follows:

[0093] S1: First, the two substrates and the composite layer are initially bonded with an adhesive, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com