Preparation method and application of nano cubic upconversion luminescent material

A technology of nano-cubes and luminescent materials, applied in the field of solar cells, can solve the problems of large particles and difficult shape control, and achieve the effects of simple preparation process, enhanced photoelectron scattering, and increased photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

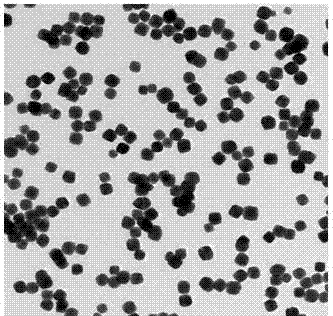

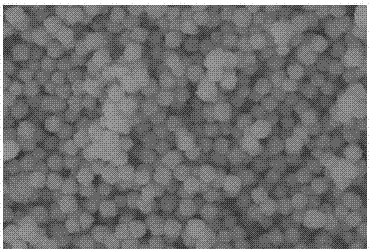

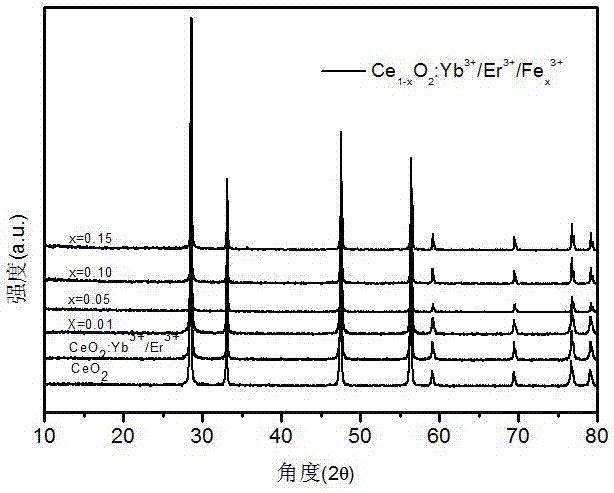

Image

Examples

Embodiment 1

[0053] TiO was screen-printed 2 The slurry is coated on FTO glass, dried at room temperature, put into a tube furnace for calcination, raised to 450 ℃ at a rate of 10 ℃ / min, calcined for 30 minutes, cooled naturally, coated with one layer and fired with a total of 6 ~ 8 floors. Finally, a layer of nanocube composite CeO 2 :Er 3+ / Yb 3+ , still at a heating rate of 10°C / min to 450°C, and calcined for 40min. Cool down naturally, soak in N719 dye for 12-24 hours, rinse with absolute ethanol, and obtain the photoanode of the dye-sensitized solar cell.

Embodiment 2

[0055] TiO was screen-printed 2 Coat the slurry on the FTO glass, dry it at room temperature, put it into a tube furnace for calcination, raise the temperature to 450 ℃ at a rate of 10 ℃ / min, calcine for 30 min, cool down naturally, apply one layer and burn one layer, and the coating is completed 6-8 floors. Finally, a layer of nanocube composite CeO 2 :Er 3+ / Yb 3+ / Fe 3+ , still at a heating rate of 10 °C / min to 450 °C, calcined for 30 min, and one layer was applied and one layer was fired. Cool down naturally, soak in N719 dye for 12-24 hours, rinse with absolute ethanol, and obtain the photoanode of the dye-sensitized solar cell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com