Method for uniformly discterbuting nano carbon tubes in liquid medium and its equipment

A technology of carbon nanotubes and liquid media, applied in the direction of mixing methods, chemical instruments and methods, fluid mixers, etc., can solve problems such as difficulty in mass production, difficulty in overcoming suction, and obstacles to the promotion and use of carbon nanotubes. To achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

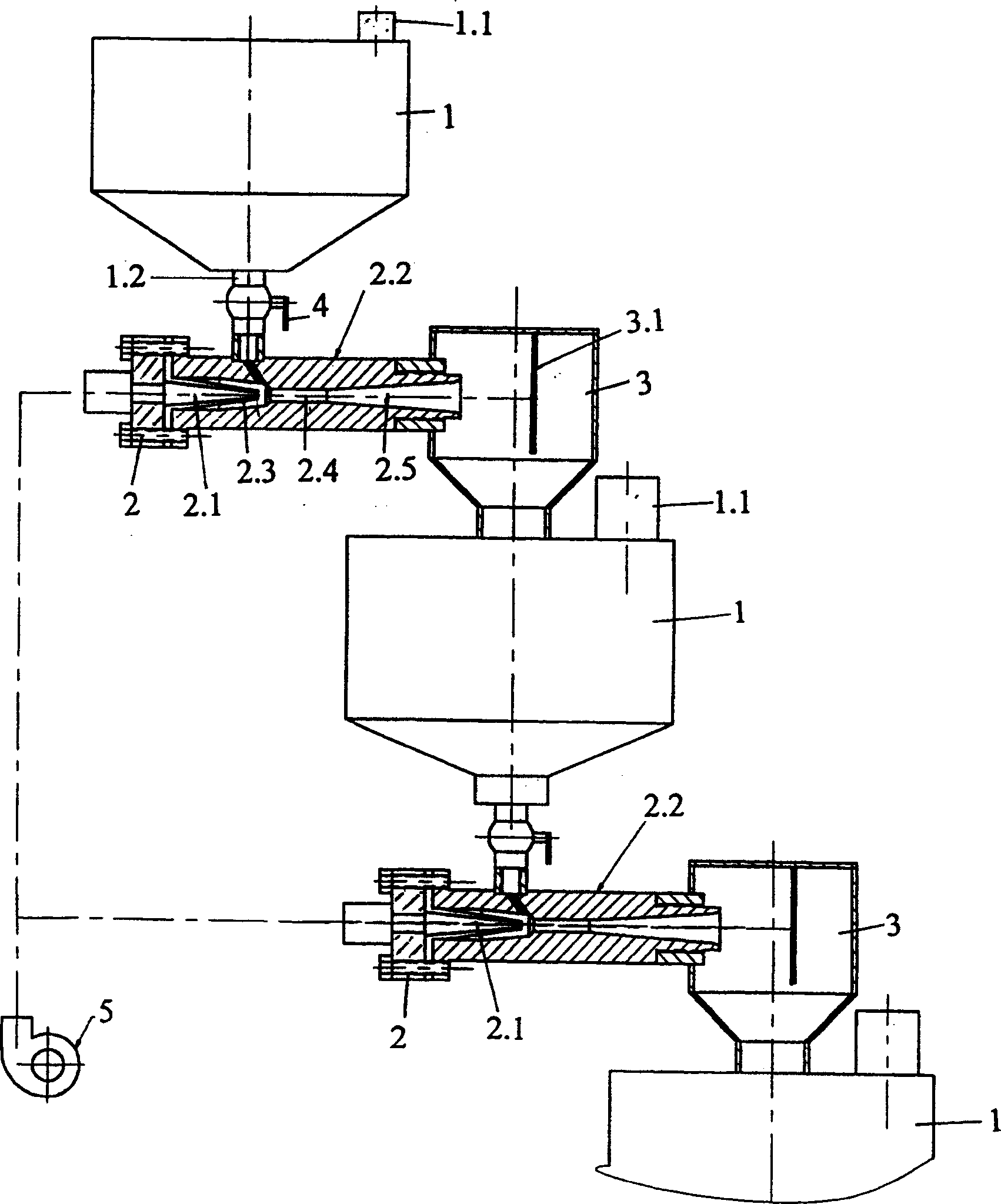

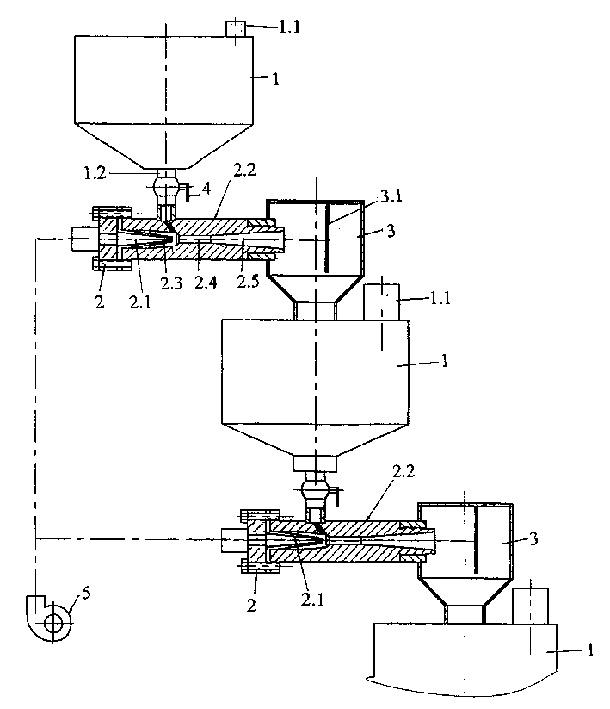

[0009] In the specific example shown in the figure, the equipment for uniformly distributing carbon nanotubes in the liquid medium has two-stage liquid flow pulling devices, and each stage of liquid flow pulling devices includes a storage tank 1 for storing the mixed solution of carbon nanotubes and liquid medium. Injection device 2, atomization collection barrel 3, storage tank has exhaust port 1.1 and discharge pipe 1.2 provided with valve 4, and stainless steel wire cluster is plugged in exhaust port 1.1 for liquid-gas separation. The discharge pipe 1.2 is connected to the pipeline of the injection device 2. The injection device has a nozzle 2.1 and a pipeline 2.2 with a rough inner wall surface. The nozzle 2.1 is inserted in the pipeline 2.2 and is coaxial with the pipeline. The discharge port is connected, and the discharge port of the pipeline 2.2 is connected with the atomization collection barrel 3, and the atomization collection barrel is provided with an axial grid pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com