Saturated polyol-ester type high-temperature chain oil and preparation method of chain oil

A polyol ester, high temperature chain technology, applied in the field of lubricating oil, can solve the problems of high temperature coking, large evaporation loss, poor lubricity, etc., and achieve the effect of small coking, low evaporation loss and enhanced anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

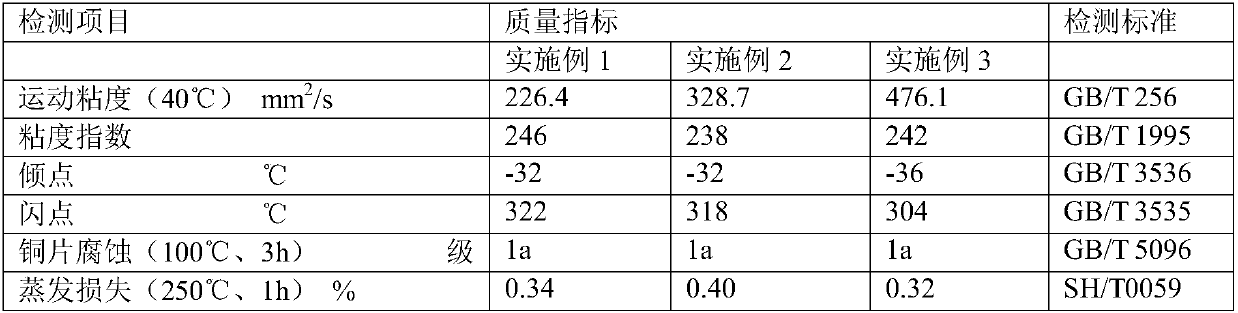

Examples

Embodiment 1

[0043]A kind of saturated polyol ester type high temperature chain oil, its composition is: 15gIrganox L101 (solid phenolic antioxidant), 20gIrganox L06 (alkylated phenyl-α-naphthylamine), 15g Vanlube RD (poly 1,2- Dihydro 2,2,4-hydroxyphenyl propionate), 5gRC8239 (benzotriazole), 5gT304 (di-n-butyl phosphite), 150g Priolube 3970 (high temperature detergent and dispersant saturated polyol ester), 80g Priolube 3986 (saturated polyol complex ester), 545g Priolube 1889 (saturated polyol ester), 155g Priolube 1851 (saturated polyol ester).

[0044] The preparation method of described saturated polyol ester type high-temperature chain oil comprises the following steps:

[0045] First weigh the base oil saturated polyol ester, add antioxidant, heat to 120°C, stir for 30 minutes until the antioxidant is completely dissolved, then add metal passivator, extreme pressure antiwear agent, high temperature detergent and dispersant, anti-oxidant Dropping agent, heated to 80°C and stirred f...

Embodiment 2

[0047] A kind of saturated polyol ester type high temperature chain oil, its composition is: 12gIrganox L115 (solid thioether phenol type antioxidant), 20gIrganox L01 (alkyl diphenylamine), 18gVanlube RD (poly 1,2-dihydro 2,2 , 4-hydroxyphenyl propionate), 5gIrgamet 39 (tolyltriazole), 5gT309 (triphenyl thiophosphate), 120gPriolube 3971 (high temperature detergent and dispersant saturated polyol ester), 100gPriolube 3986 (high temperature detergent and dispersant agent saturated polyol ester), 220g Priolube3987 (saturated polyol ester), 550g Priolube 2046 (saturated polyol ester).

[0048] The preparation method of described saturated polyol ester type high-temperature chain oil comprises the following steps:

[0049] First weigh the base oil saturated polyol ester, add antioxidant, heat to 115°C, stir for 35 minutes until the antioxidant is completely dissolved, then add metal passivator, extreme pressure antiwear agent, high temperature detergent and dispersant, anti-oxidant...

Embodiment 3

[0051] A kind of saturated polyol ester type high-temperature chain oil, its composition is: 12gIrganox L101 (solid phenolic antioxidant), 15gVanlube 81 (to p-diisooctyl diphenylamine), 15g Vanlube RD (poly 1,2-diphenylamine) Hydrogen 2,2,4-hydroxyphenyl propionate), 5g Vanlube 887 (N, N dialkylaminomethylene benzene triazole), 5g T309 (triphenyl phosphorothioate), 150g Priolube 3970 (high temperature clean dispersion agent saturated polyol ester), 100g KETJENLUBE 9505 (saturated polyol complex ester), 100g Priolube 3987 (saturated polyol ester), 598g Priolube 1851 (saturated polyol ester).

[0052] The preparation method of described saturated polyol ester type high-temperature chain oil comprises the following steps:

[0053] First weigh the base oil saturated polyol ester, add antioxidant, heat to 125°C, stir for 25 minutes until the antioxidant is completely dissolved, then add metal passivator, extreme pressure antiwear agent, high temperature detergent and dispersant, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com