Downhole tool electromagnetic rotating speed control pup joint

A technology for speed control and downhole tools, which is applied to drilling equipment, wellbore flushing, wellbore/well components, etc. It can solve the problems of poor control of tool speed and failure of speed limiting ring, etc., and achieves simple structure and applicability Strong, novel design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

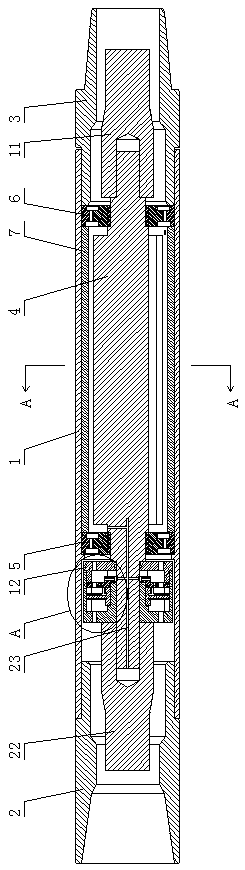

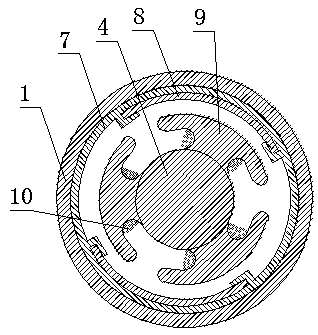

[0026] The electromagnetic speed control pup joint of the downhole tool includes a casing 1, an upper joint 2, a lower joint 3, a rotating shaft 4 and a switch device. The joint 3, the upper righting bearing 5 and the lower righting bearing 6 which are symmetrically arranged in the housing 1 are equipped with a rotating shaft 4, and a plurality of T-shaped pieces 9 are axially evenly distributed on the circumference of the rotating shaft 4, and the T-shaped pieces 9 are wound A coil 10 is formed. On the rotating shaft 4 between the upper righting bearing 5 and the lower righting bearing 6, a magnet 8 is symmetrically installed through a support frame 7, and a lower spline joint 11 is installed on the upper side of the rotating shaft 4 outside the lower righting bearing 6, and the outer side of the upper righting bearing 5 On the rotating shaft 4, a switching device is installed with interference.

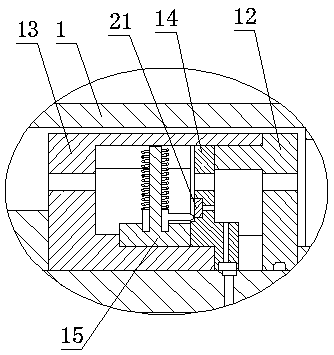

[0027] The switch device includes a switch base 12, a guide plate 13, a switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com