Method for predicting characteristics of dynamic icing ice type microstructure of aircraft

A prediction method and microstructure technology, applied in the testing of machine/structural components, measuring devices, aerodynamic tests, etc., can solve the problem of difficult to predict the detailed characteristics of dynamic icing and icing patterns, and the inability to establish icing conditions and physical characteristics of icing Quantitative relationship, restricting aircraft icing characteristics, flight safety hazards and other issues to improve the refined prediction level, to achieve the effect of improving the refined level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

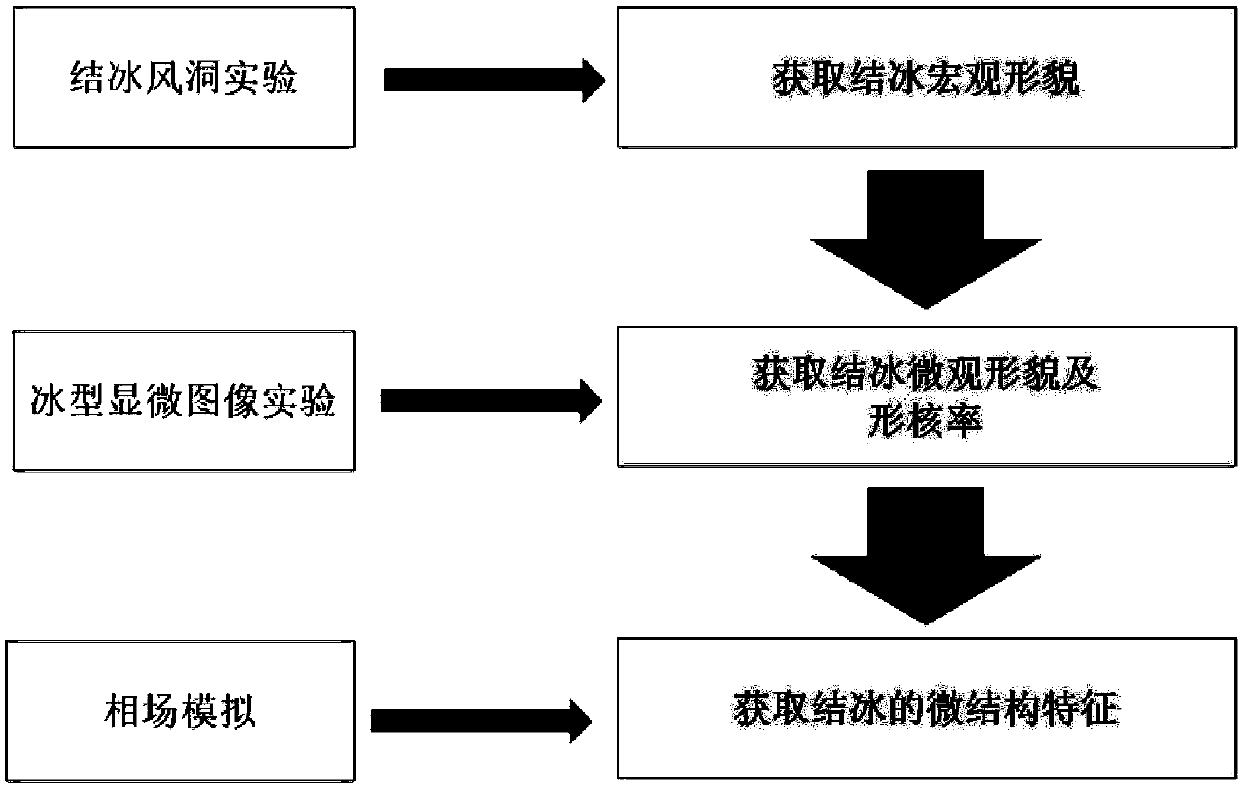

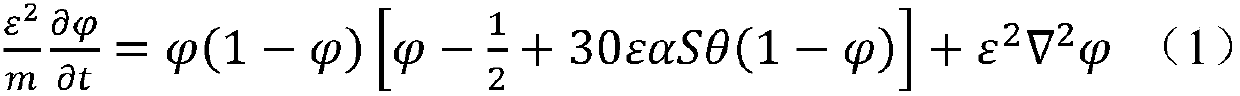

[0013] The present invention adopts the method combining wind tunnel experiment, microscopic image experiment and phase field simulation, establishes a kind of method that can effectively predict the microstructural characteristic of aircraft dynamic icing icing, such as figure 1 shown, including the following steps:

[0014] 1. In the icing wind tunnel, the incoming flow velocity, water drop diameter and liquid water content are fixed, and the incoming flow temperature is changed to carry out icing wind tunnel experiments to obtain the icing macroscopic morphology of the model surface under different temperature conditions.

[0015] 2. In view of the lack of data on the nucleation rate of aircraft dynamic icing process at home and abroad, on the basis of icing wind tunnel experiments, carry out ice microscopic image experiments to obtain the microscopic morphology and nucleation rate of icing:

[0016] Select the ice phase in the middle part of the experimental model, slice a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com