Device for forging hydraulic cylinder body

A technology of hydraulic cylinder and cylinder block, applied in the driving device of forging press, forging/pressing/hammer device, swaging press, etc., can solve the problems of difficulty, long cycle, poor mechanical performance and reliability, etc. To achieve the effect of reducing heat and good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

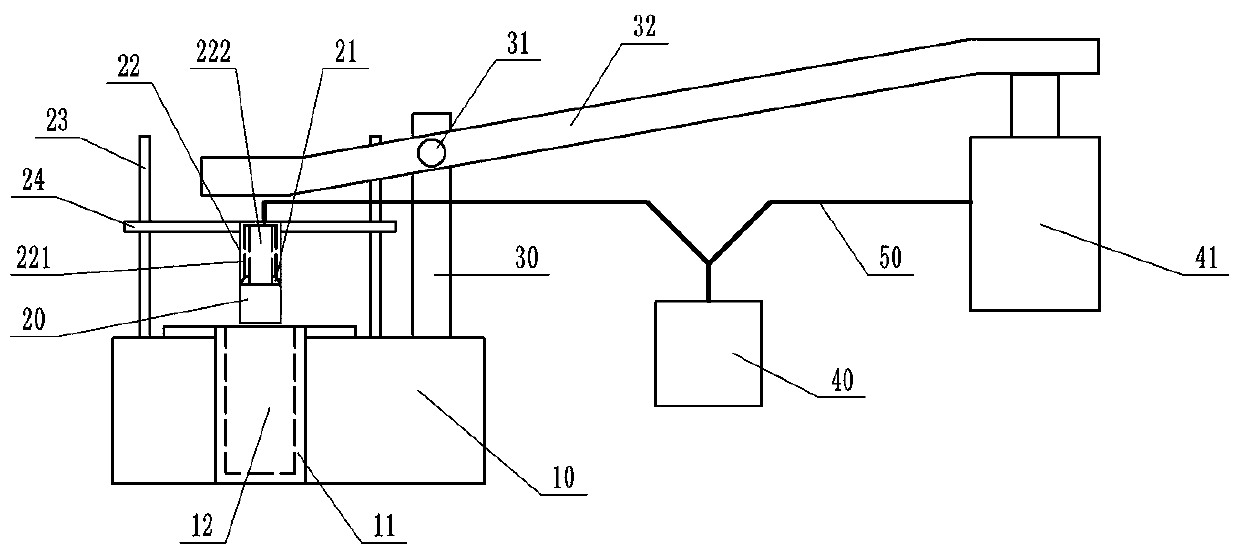

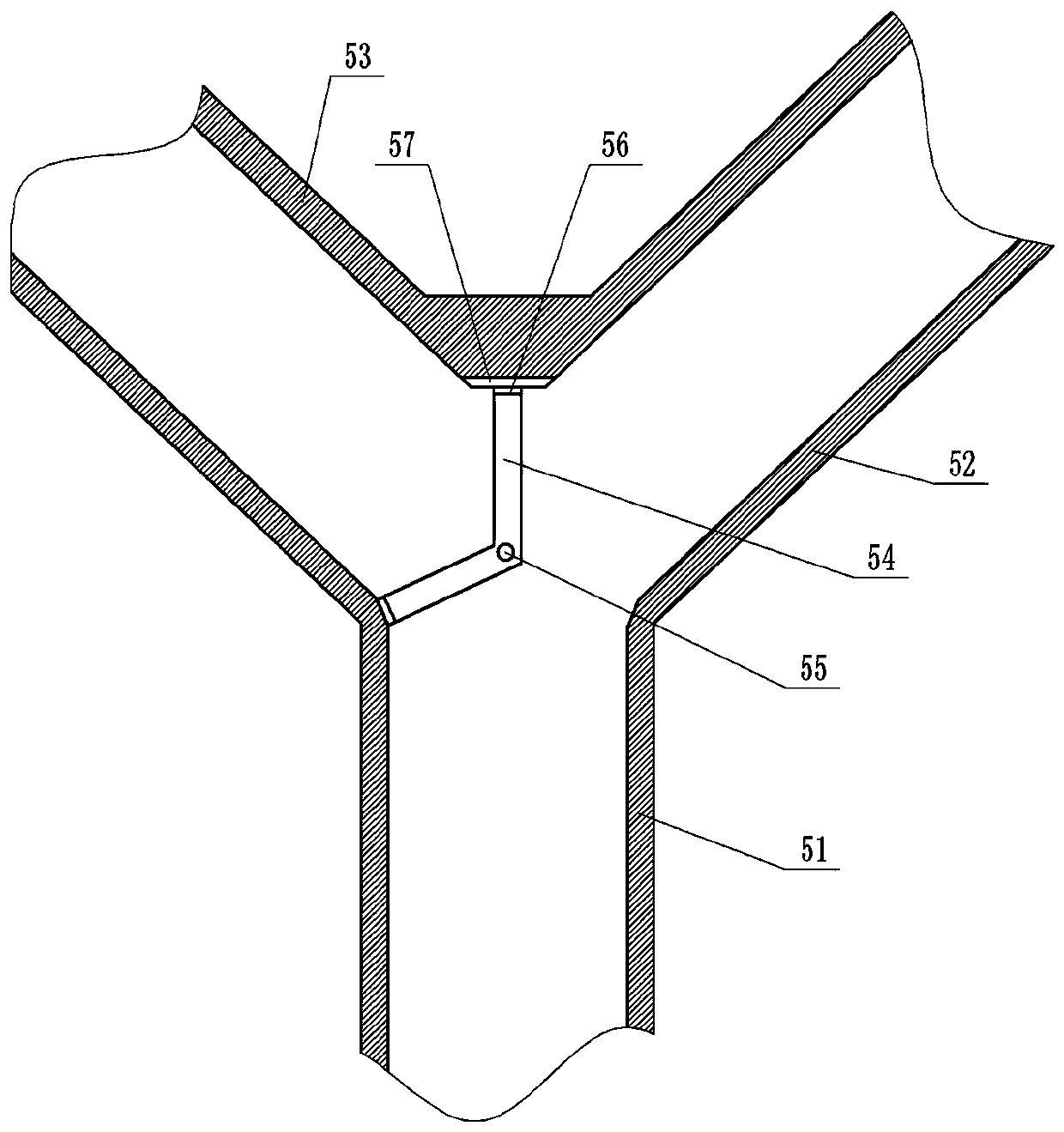

[0017] The reference signs in the accompanying drawings of the description include: frame 10, die 11, groove 12, forging head 20, air bag cover 21, forging rod 22, air outlet channel 221, hydraulic chamber 222, guide rod 23, fixed plate 24, Strut 30, fulcrum 31, pressure rod 32, hydraulic pump 40, piston cylinder 41, connecting pipe 50, main pipe 51, first branch pipe 52, second branch pipe 53, stopper 54, rotating shaft 55, magnetic block 53, permanent magnet 57.

[0018] Such as figure 1 , figure 2 As shown, a device for forging a hydraulic cylinder block includes a frame 10, a die 11, a forging hole unit and a power unit, the die 11 is fixed below the frame 10, and the die 11 is provided with a forging cylinder The groove 12 of the body, the forging hole unit is located above the die 11; the forging hole unit includes a forging head 20, an air bag cover 21, a forgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com