Fully-automatic solder paste printing machine capable of sucking powder

A solder paste printing machine, fully automatic technology, used in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of insufficient blade angle adaptability, inability to meet deflection, etc., to increase the tilt angle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

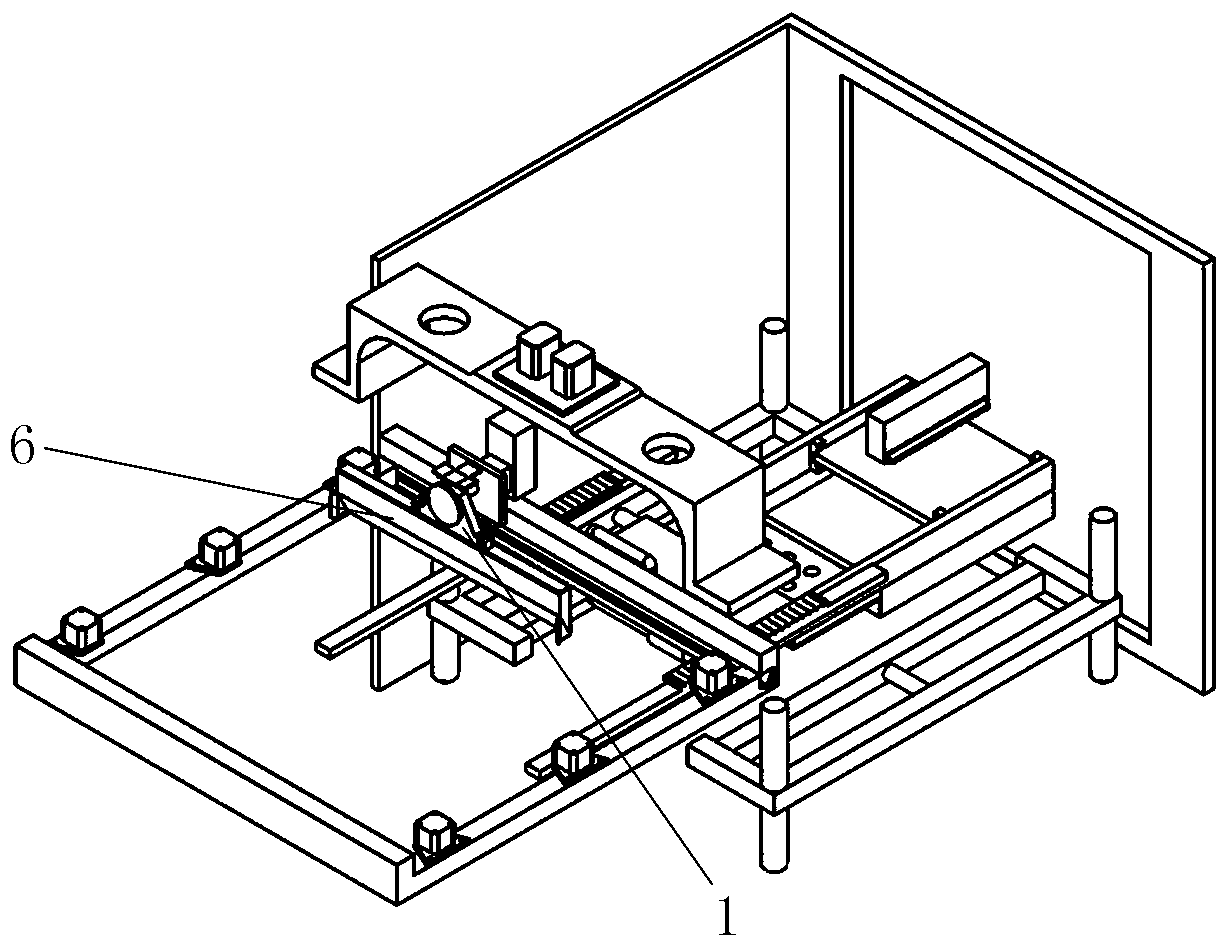

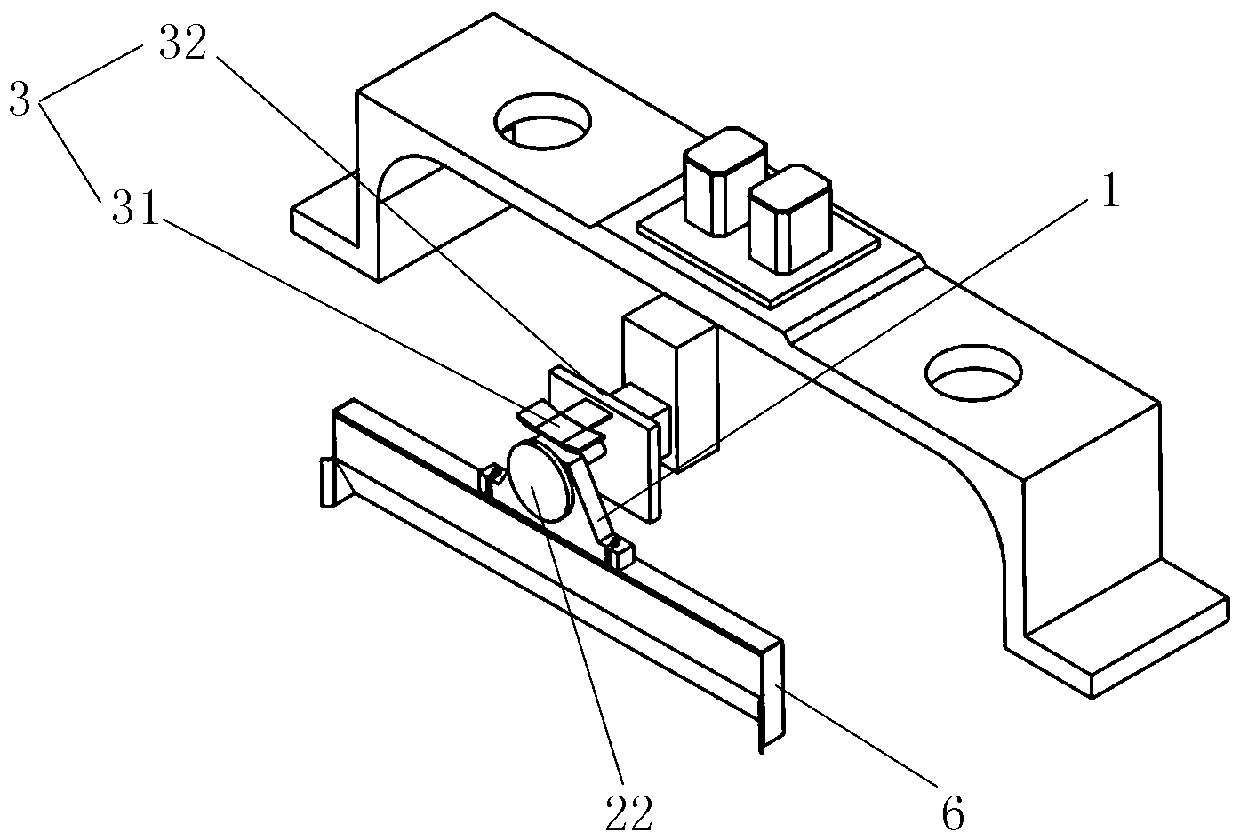

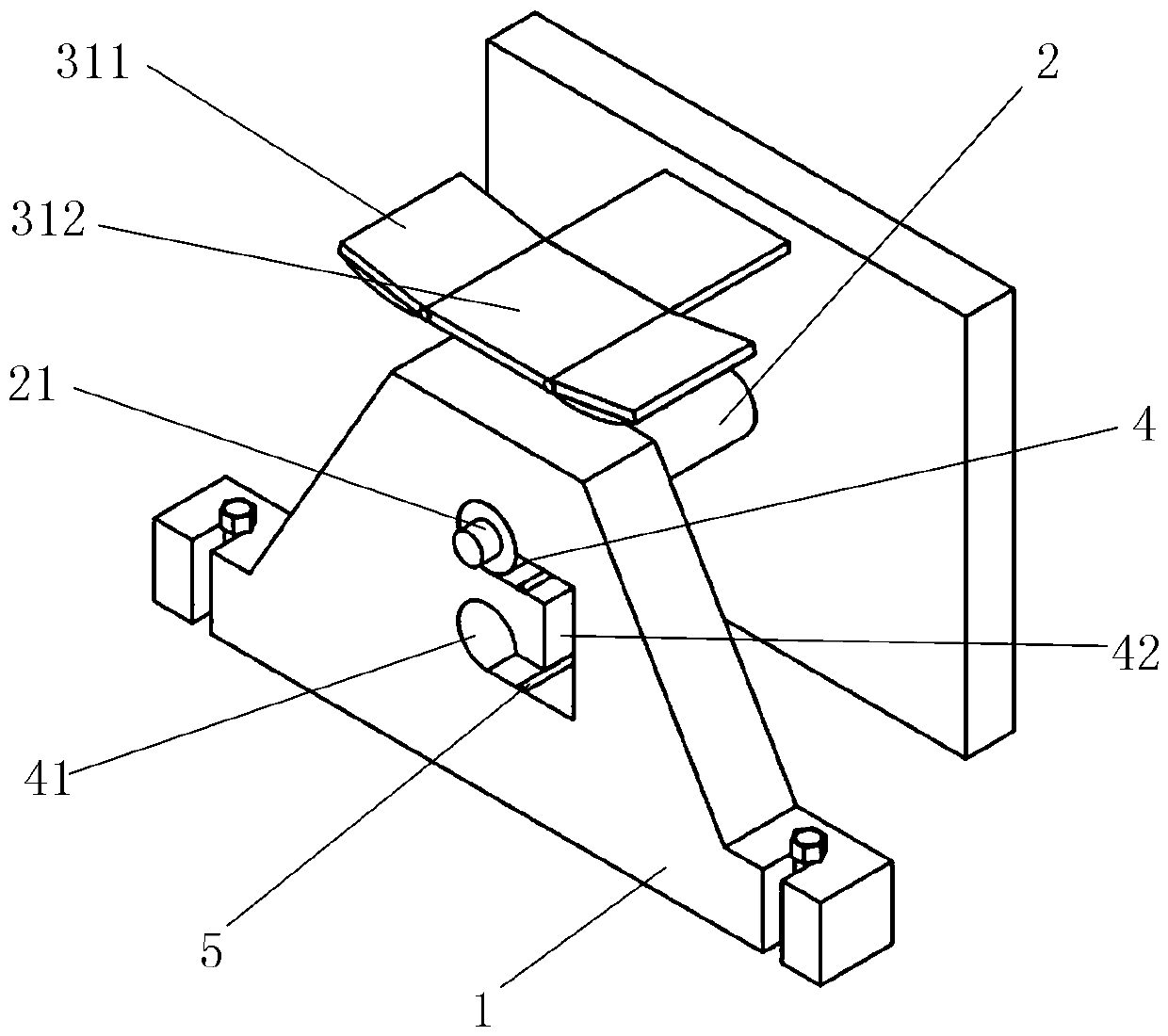

[0041] Example 1, such as figure 1 Shown is a schematic diagram of the structure of a fully automatic solder paste printing machine that can absorb powder. A fully automatic solder paste printing machine that can absorb powder includes a casing, a clamping and lifting system, a platform correction system, a guide rail transportation system, and a steel mesh. Frame clamping system, doctor blade printing system and subsequent cleaning system, among which, such as figure 2 , image 3 As shown, the scraper printing system includes a fixed frame 1, a through shaft 2 and a scraper 6, the scraper 6 is fixed at the lower end of the fixed frame 1, the through shaft 2 includes a threading part 21, and a tightening part 22 installed on the threading part 21, The fixed frame 1 is sleeved on the threading part 21 through the through hole 4, and there is a turning part 3 above the fixing frame 1. The turning part 3 includes a turning surface 31 and is used to connect the threading part 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com