Paper collecting device for lithographic printing machine

A technology of printing machine and lithography, which is applied in the direction of stacking receiving device, transportation and packaging, sending objects, etc. It can solve the problems of high manufacturing cost and complicated structure of paper receiving device, so as to reduce paper waste, simple structure and prevent paper waste. fluttering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

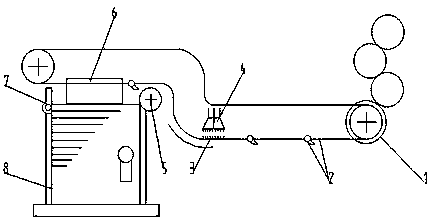

[0011] like figure 1 As shown, a paper delivery device of a lithographic printing machine is mainly composed of a delivery cylinder 1, a delivery chain and a delivery tooth row 2, a chain guide rail 3, a powder spraying device 4, a braking roller 5, a side flush cardboard 6, and a cardboard stop 7. The paper table lifting mechanism 8, the printing plate cylinder 9, the rubber cylinder 10 and the impression cylinder 11 are composed. The upper left side of the paper table lifting mechanism 8 is provided with a cardboard stopper 7, and the paper table lifting mechanism 8 is provided with a side alignment plate. Cardboard 6, a brake roller 5 is arranged on the upper right side of the paper table lifting mechanism 8, the powder spraying device 4 is arranged on the right side of the paper table lifting mechanism 8, and a paper delivery chain and a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com