Diatomite modified concrete and preparation method thereof

A diatomite and concrete technology, applied in the field of diatomite modified concrete and its preparation, can solve the problems of reducing the strength of high-strength concrete, reducing the brittleness of high-strength concrete, and large shrinkage of high-strength concrete, so as to reduce the brittleness, improve the problem of early cracking, The effect of reducing the cracked area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

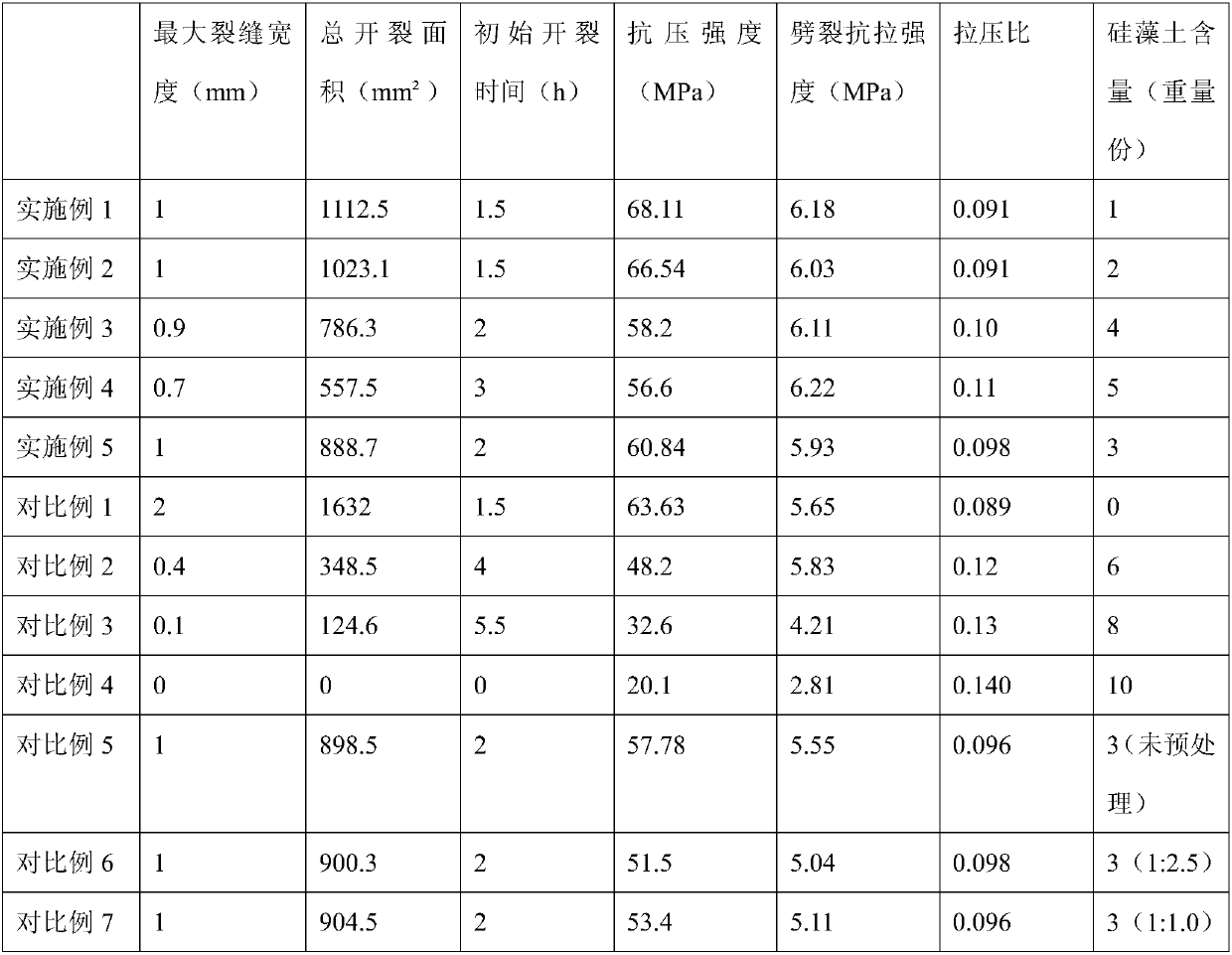

Examples

Embodiment 1

[0042] A preparation method of diatomite modified concrete, comprising the following steps:

[0043] 1), diatomite pretreatment: mix 1 weight part of diatomite and 1.5 weight parts of tap water, carry out water absorption treatment, stir evenly, make the material after mixing be in saturated surface dry state;

[0044] 2), 15 parts by weight of cement, 25 parts by weight of river sand and 40 parts by weight of crushed stone are poured into the mixer for dry mixing, the average particle size of the river sand is 0.5 mm, and the average particle size of the crushed stone is 15 mm;

[0045] 3) Dissolving 0.2 parts by weight of naphthalene-based high-efficiency water-reducer in water to form an aqueous water-reducer solution;

[0046] 4) Pour the aqueous solution of naphthalene-based high-efficiency water reducer into the mixer for wet mixing;

[0047] 5) Pour the saturated surface-dried diatomaceous earth into the mixer, continue stirring, and obtain concrete evenly;

[0048] 6...

Embodiment 2

[0052] A preparation method of diatomite modified concrete, comprising the following steps:

[0053] 1), diatomite pretreatment: mix 2 parts by weight of diatomite and 3.4 parts by weight of tap water, perform water absorption treatment, and stir evenly, so that the mixed material is in a saturated surface-dry state;

[0054] 2) Pour 20 parts by weight of cement, 30 parts by weight of river sand and 45 parts by weight of crushed stone into a mixer for dry mixing. The average particle size of the river sand is 0.7 mm, and the average particle size of the crushed stone is 25 mm;

[0055] 3) Dissolving 0.5 parts by weight of naphthalene-based high-efficiency water-reducer in water to form an aqueous water-reducer solution;

[0056] 4) Pour the aqueous solution of naphthalene-based high-efficiency water reducer into the mixer for wet mixing;

[0057] 5) Pour the saturated surface-dried diatomaceous earth into the mixer, continue stirring, and obtain concrete evenly;

[0058] 6) ...

Embodiment 3

[0062] A preparation method of diatomite modified concrete, comprising the following steps:

[0063] 1), diatomite pretreatment: mix 4 parts by weight of diatomite and 6.4 parts by weight of tap water, perform water absorption treatment, and stir evenly, so that the mixed material is in a saturated surface-dry state;

[0064] 2), 18 parts by weight of cement, 28 parts by weight of river sand and 42 parts by weight of crushed stone are poured into the mixer in proportion to dry mixing. The average particle diameter of the river sand is 0.6mm, and the average particle diameter of the crushed stone is 20mm;

[0065] 3) Dissolving 0.3 parts by weight of naphthalene-based high-efficiency water reducer in water to form an aqueous water reducer solution;

[0066] 4) Pour the aqueous solution of naphthalene-based high-efficiency water reducer into the mixer for wet mixing;

[0067] 5) Pour the saturated surface-dried diatomaceous earth into the mixer, continue stirring, and obtain c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com