A kind of high performance concrete based on artificial sand and its preparation method and application

A high-performance concrete and artificial sand technology, applied in the field of concrete materials, can solve problems such as inapplicability, and achieve the effects of reducing consumption, improving compactness, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

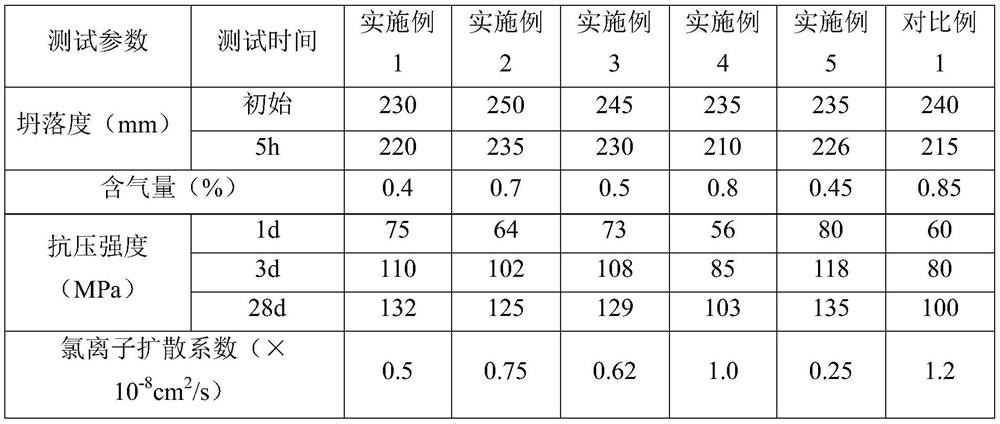

Examples

Embodiment 1

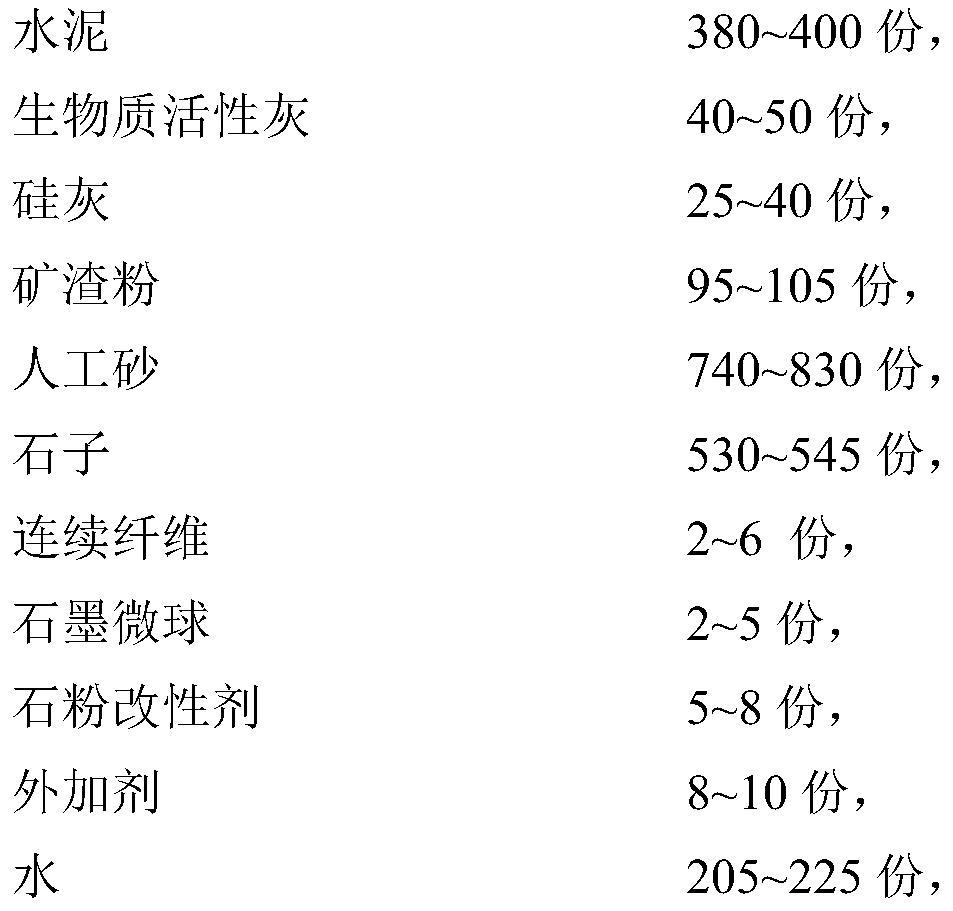

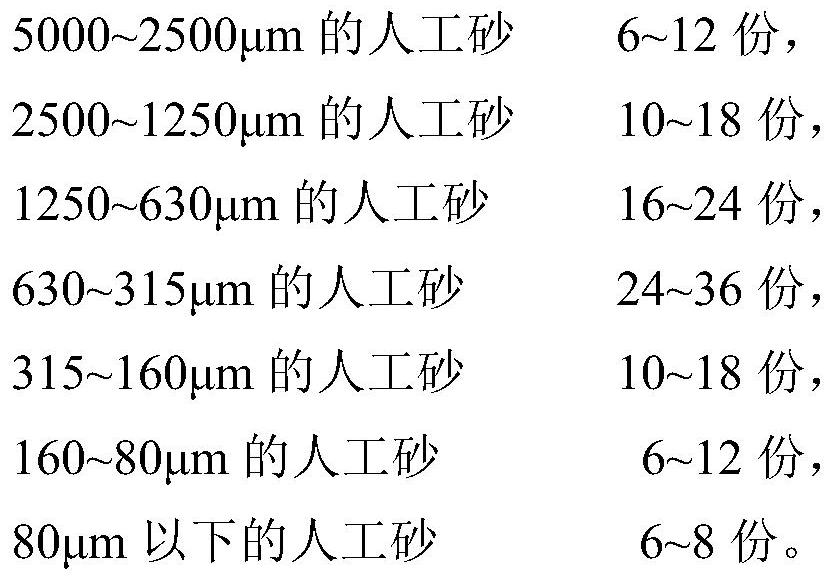

[0030] A concrete comprising the following raw materials in parts by weight:

[0031] 400 parts of cement, 45 parts of biomass active ash, 30 parts of silica fume, 100 parts of slag powder, 800 parts of artificial sand, 540 parts of gravel, 4 parts of continuous fiber of 0.16-2.5mm, 4 parts of graphite microspheres, stone powder modifier 6 parts, 9 parts of admixture, 210 parts of water.

[0032] Among them, the cement is P.O 42.5 Portland cement, and the fineness requirement is 0.08mm square hole sieve 3%;

[0033] silica fume SiO 2 Content > 92%, particle size 2 / kg;

[0034] Biomass active ash is a mixture of rice husk ash, peanut husk ash and corn stalk ash; the particle size of biomass active ash is less than 10 μm; the SiO of rice husk ash 2 Content > 92%, SiO in peanut shell ash 2 and Al 2 o 3 Content > 70%, SiO of corn stalk ash 2 The content is more than 75%. The calcining temperature for preparing the biomass active ash is 600° C., and the holding time is 3 ho...

Embodiment 2

[0047] A kind of concrete, the difference with embodiment 1 is that raw material and parts are:

[0048] 380 parts of cement, 50 parts of biomass active ash, 25 parts of silica fume, 105 parts of slag powder, 740 parts of artificial sand, 530 parts of stone, 2 parts of continuous fiber of 0.16-2.5mm, 2 parts of graphite microspheres, stone powder modifier 5 parts, 8 parts of admixture, 225 parts of water.

Embodiment 3

[0050] A kind of concrete, the difference with embodiment 1 is that raw material and parts are:

[0051] 400 parts of cement, 40 parts of biomass active ash, 40 parts of silica fume, 95 parts of slag powder, 830 parts of artificial sand, 545 parts of stone, 6 parts of continuous fiber of 0.16-2.5mm, 5 parts of graphite microspheres, stone powder modifier 8 parts; 10 parts of admixture; 205 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com