A kind of lithium-ion battery non-aqueous electrolyte and lithium-ion battery

A non-aqueous electrolyte and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problem that fluorinated cyclic carbonate is prone to oxidative decomposition, cannot improve the high-pressure resistance and high temperature of non-aqueous electrolyte, and the oxidative decomposition of electrolyte system And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the lithium-ion battery of the present invention is a method for preparing lithium batteries known in the art, for example, including setting a separator between the prepared positive electrode and the negative electrode, winding or folding to form an electric core, and the electric core is accommodated in Inject the electrolyte into the battery case, and then seal the battery case to obtain a lithium-ion battery.

[0035] The non-aqueous electrolyte solution for lithium-ion batteries provided by the invention has higher high-voltage resistance performance and higher oxidation decomposition potential, and meanwhile, the battery prepared by using the non-aqueous electrolyte solution has good cycle performance and charge-discharge performance.

[0036] The lithium ion battery provided by the invention has higher energy density, first charge and discharge performance, and good high pressure resistance and cycle performance.

Embodiment 1

[0039] (1) Preparation of non-aqueous electrolyte:

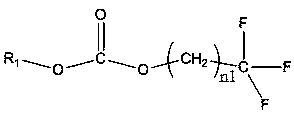

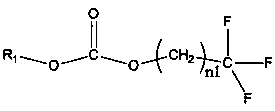

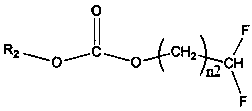

[0040] In an argon glove box, ethylene carbonate, diethyl carbonate, and ethyl methyl carbonate were made into a non-aqueous solvent in a ratio of 3:4:3, and then LiPF with a concentration of 1.1mol / L was added 6 , then add the first additive trifluoropropylene carbonate (chain fluorocarbonate shown in the application structural formula (1), wherein R1 is a methyl group, n is 1) and the second additive fluorinated cyclic disulfonic acid benzene Esters (cyclic disulfonic acid phenyl ester compounds shown in the structural formula (3) of the present application, wherein R2 is a fluorine atom), prepare 100 parts by weight of the lithium-ion battery non-aqueous electrolyte, which is denoted as C1; wherein the non-aqueous Based on the total mass of the electrolyte, the content of the first additive is 10 parts by weight, and the content of the second additive is 1 part by weight.

[0041] (2) Preparation of lithium ion battery: ...

Embodiment 2

[0044] (1) Preparation of non-aqueous electrolyte:

[0045] In an argon glove box, make ethylene carbonate, diethyl carbonate, and ethyl methyl carbonate in a ratio of 3:4:3 as a non-aqueous solvent, and then add LiPF with a concentration of 1.1mol / L and a volume of 100ml 6 , then add the first additive ethylene propyl trifluorocarbonate (the chain fluorocarbonate shown in the application structural formula (1), wherein R Be ethyl, n is 1 and the second additive cyclic disulfonic acid benzyl Nitrile ester (cyclic disulfonic acid phenyl ester compound shown in the application structural formula (3), wherein R2 is a nitrile group), prepares 100 parts by weight of lithium-ion battery non-aqueous electrolyte, denoted as C2; wherein non-aqueous electrolyte Based on the total mass of the aqueous electrolyte, the content of the first additive is 10 parts by weight, and the content of the second additive is 1 part by weight.

[0046] (2) Preparation of lithium ion battery:

[0047] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com