Device and method for solving aggregation jam of compressor segment of styrene off-gas

A tail gas compressor and compressor technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve problems such as high cost, unsatisfactory effect, and large impact on production load, and achieve the goal of reducing energy consumption of the device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

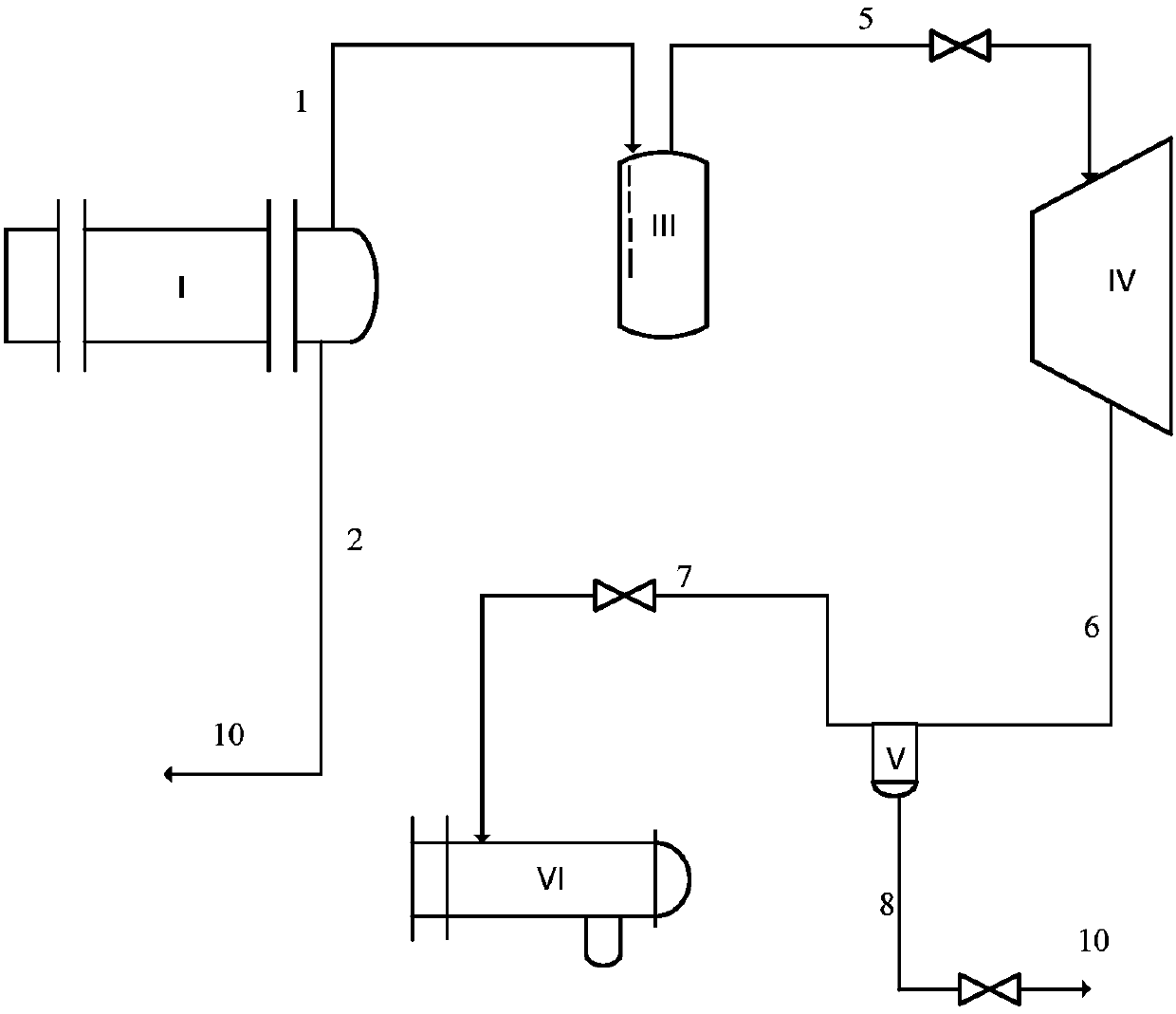

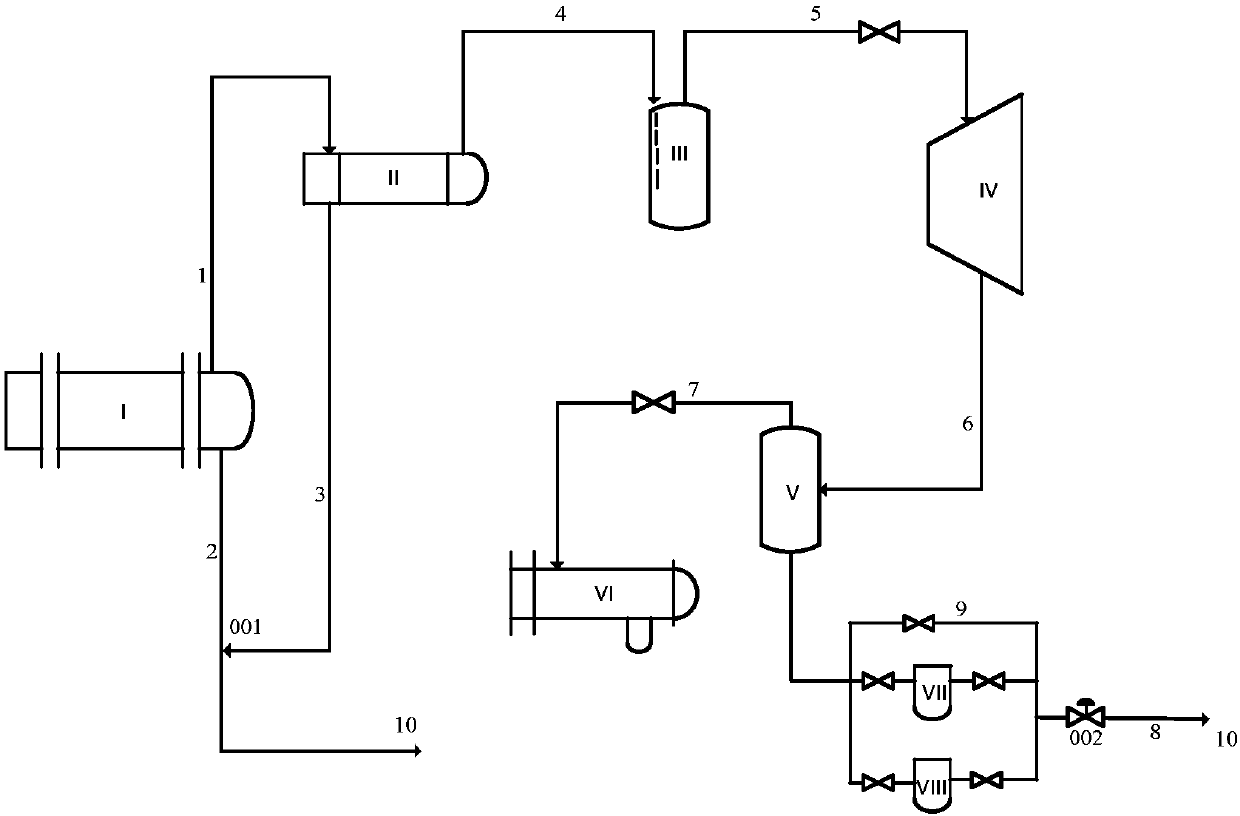

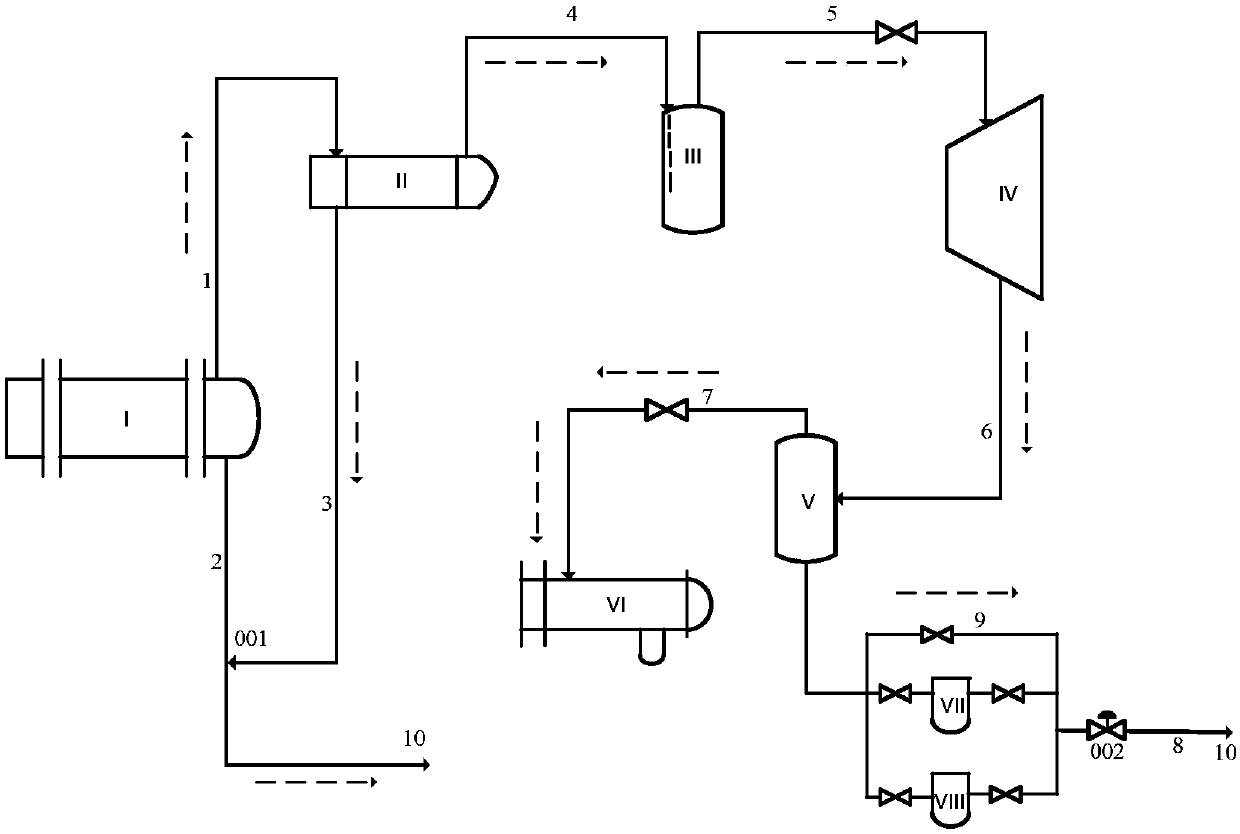

[0033] The present invention proposes a device and method for solving the polymerization blockage of the styrene tail gas compressor section. In order to make the advantages and technical solutions of the present invention clearer, the present invention will be described in detail below in conjunction with specific examples.

[0034] 1, 2, 3, 4 ... 9 in the pipeline A1, pipeline B2, pipeline C3, pipeline D4 ... pipeline I9 that appear in the following embodiments are representative reference signs (attached figure 2 reference signs in ).

[0035] Such as figure 2 Shown, the present invention is a kind of device that solves the polymer blockage of styrene tail gas compressor section, and it comprises aftercooler I, compressor inlet cooler II, compressor suction tank III, tail gas compressor IV, liquid separation tank V and tail gas Pipeline B2 is installed at the bottom of the tube side of cooler VI and aftercooler I, and pipeline B2 is connected to oil-water separator 10, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap