Surface treatment method of chemical fiber cotton product

A technology for surface treatment and cotton products, applied in fiber treatment, physical treatment, fiber types, etc., can solve the problems affecting the air permeability and softness of chemical fiber cotton products, and achieve the effect of simple treatment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

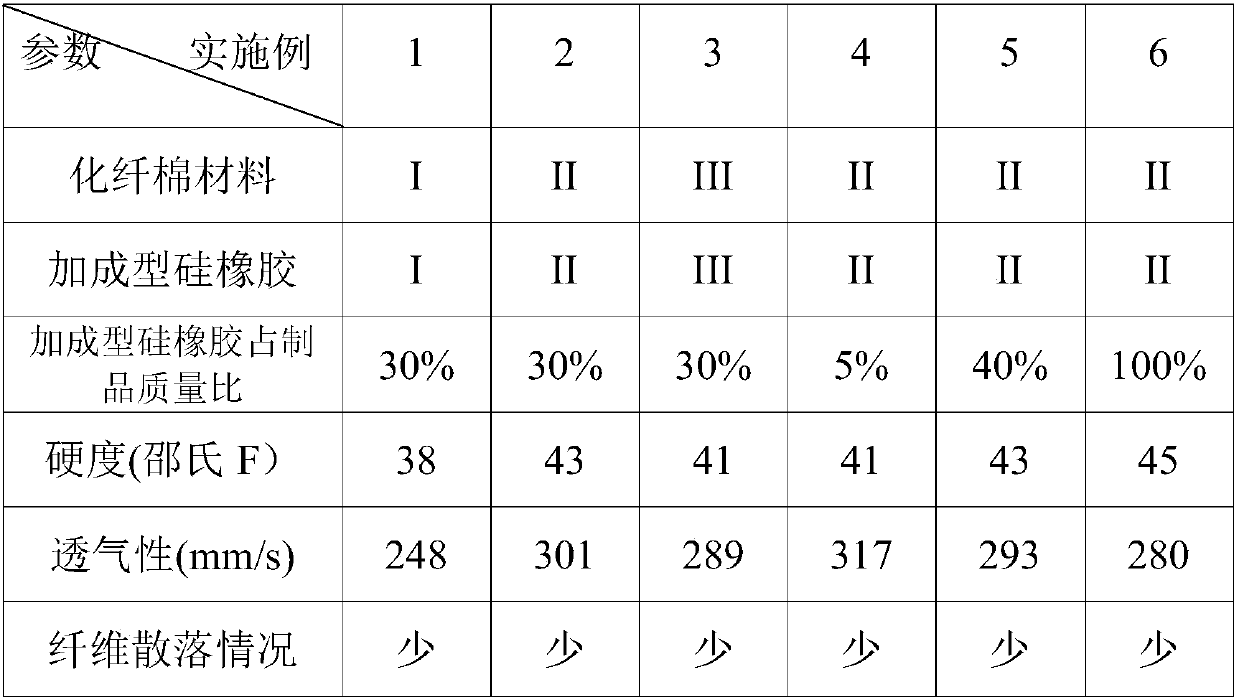

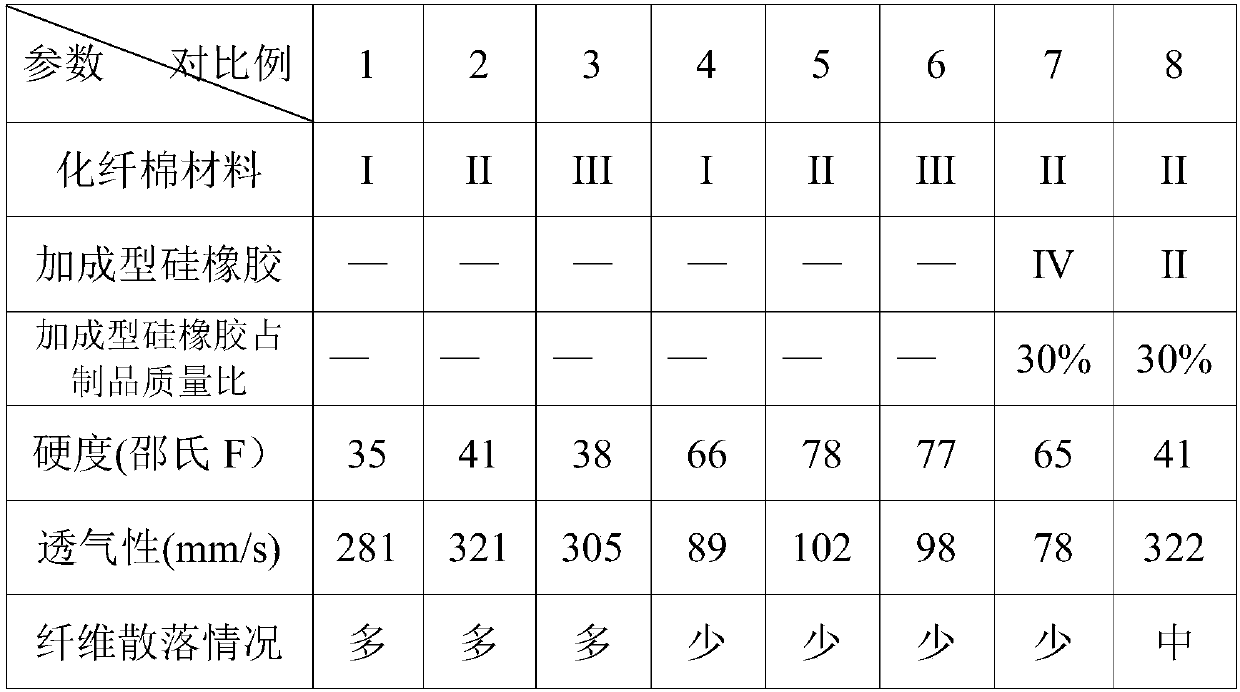

Embodiment 1~6

[0041] Take a large piece of chemical fiber cotton material and cut it into a sample of 20cm×20cm×1cm with a utility knife; spray the addition-type silicone rubber solution or the addition-type silicone rubber emulsion evenly on each surface of the cube sample by air spraying method, After spraying, put the sample into an oven at 150°C and bake for 30 minutes; take out the sample and put it into a mold, set the temperature of the mold to 20°C above the melting point of the fiber material, and press and heat for 1 minute. Take out the sample and let it cool down to room temperature naturally.

[0042] Test samples for hardness, air permeability and fine fiber shedding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com