Intelligent filling type epoxy coating steel strand and manufacturing method

An epoxy coating and intelligent filling technology, which is applied in the field of steel strands, can solve the problems that fiber grating sensors cannot be packaged, and hollow tubular central wires cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

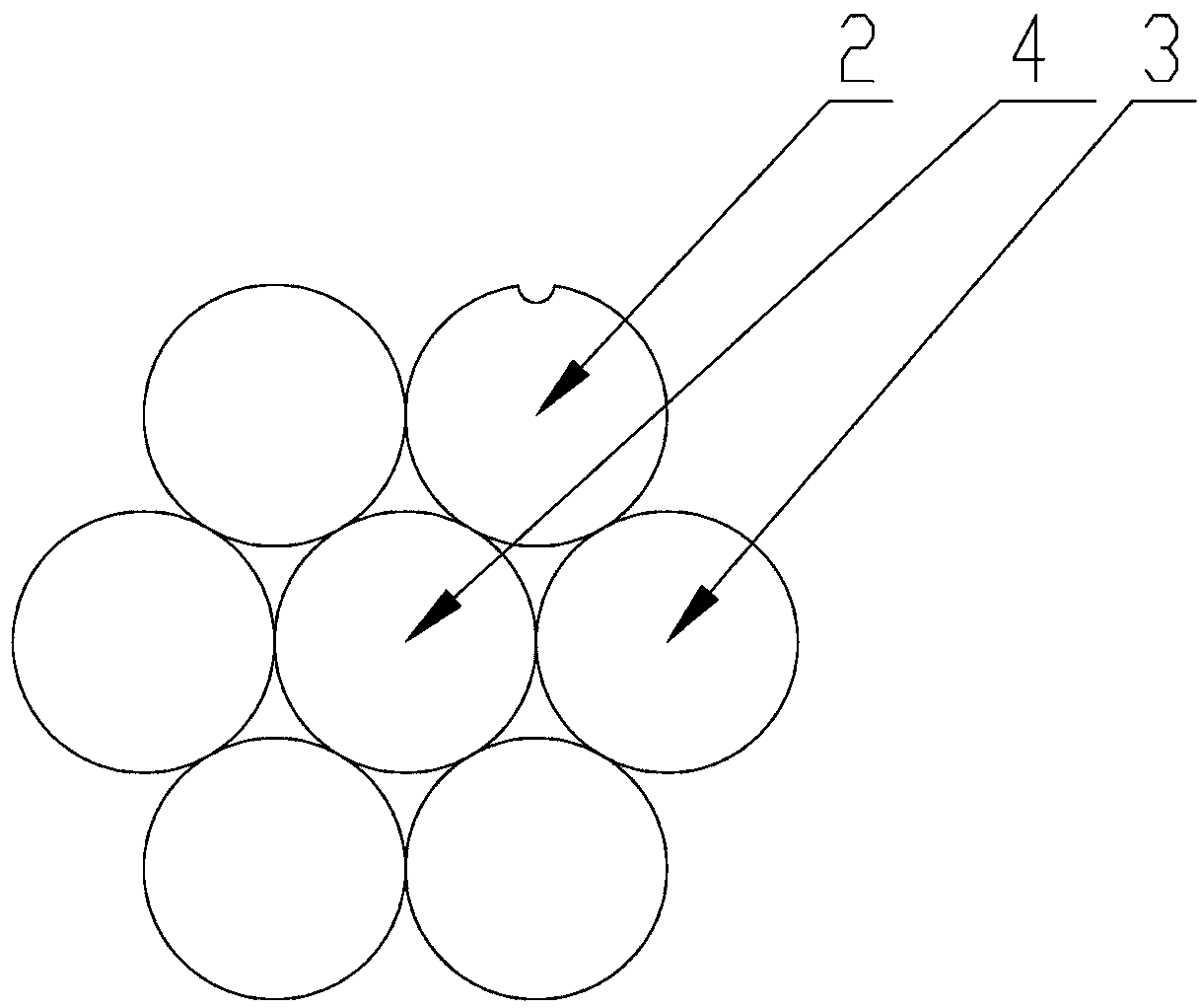

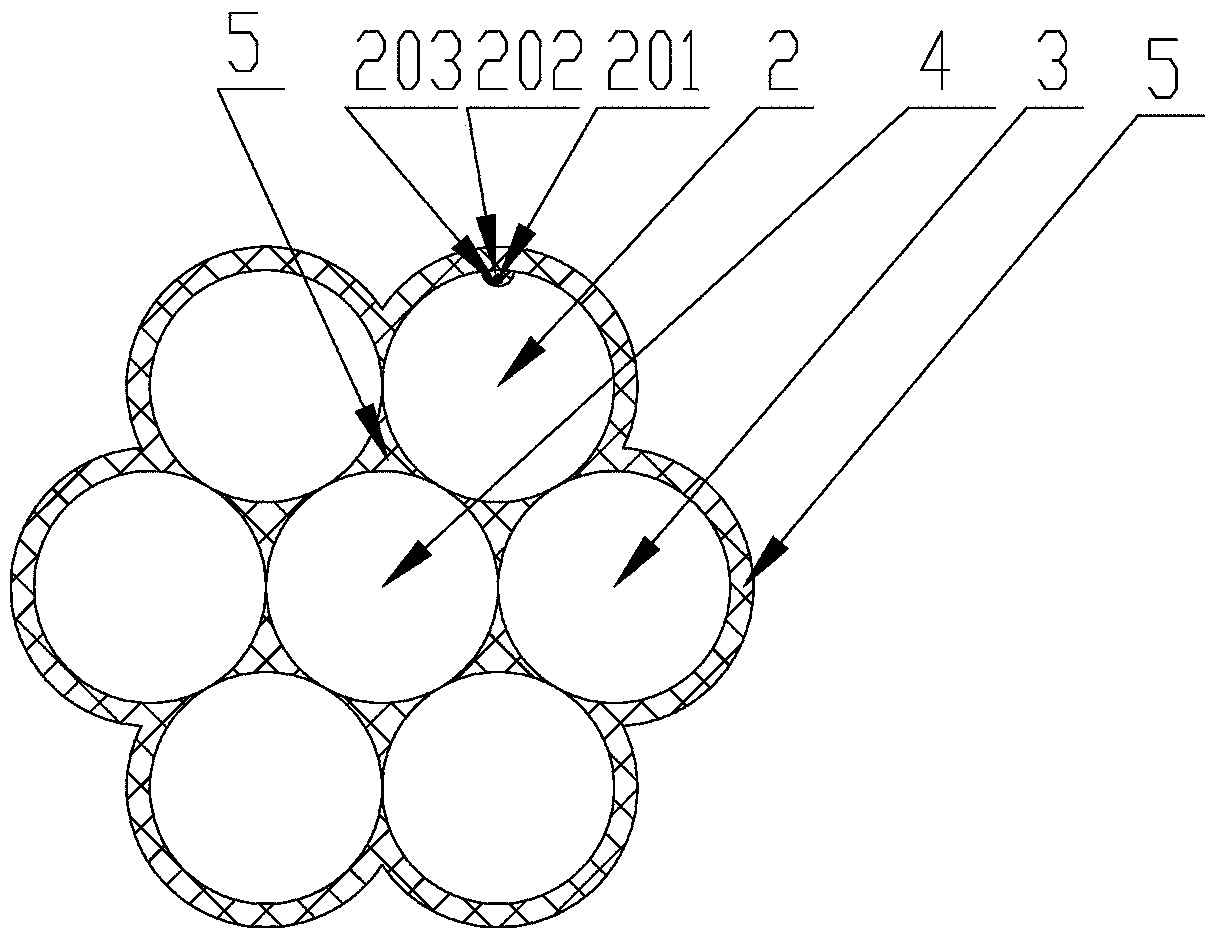

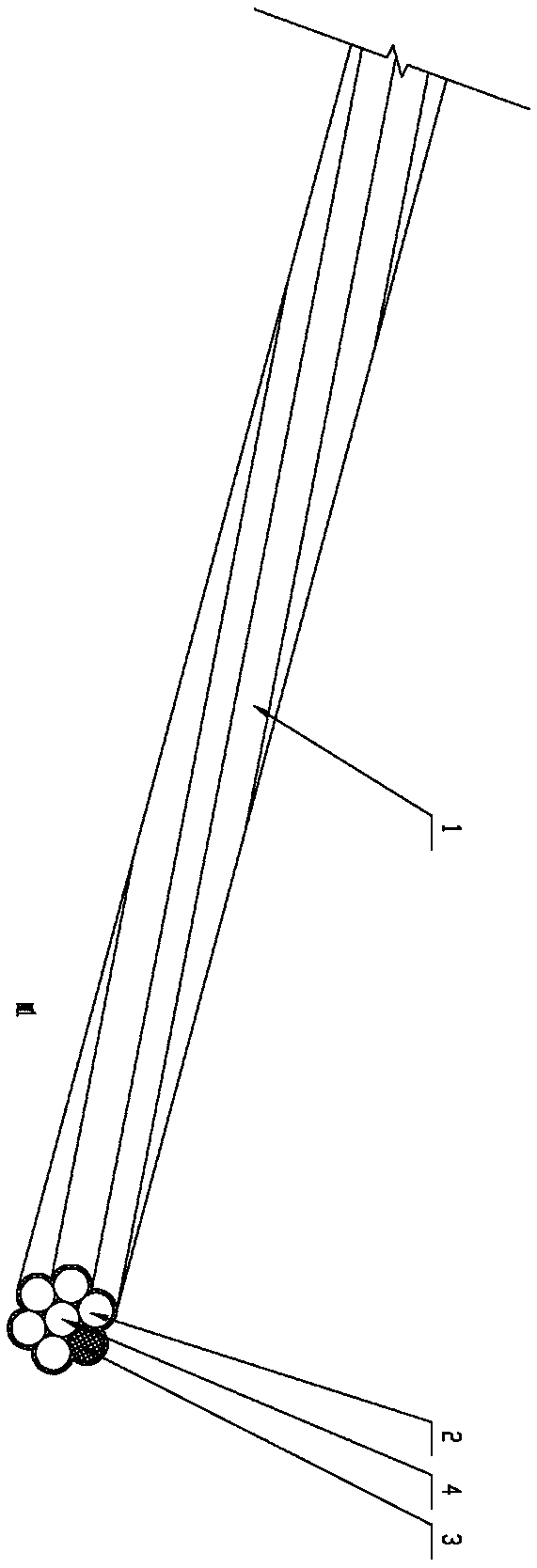

[0024] Such as figure 1 , figure 2 As shown, the smart filled epoxy coated steel strand 1 is first drawn out of the grooved side wire 2, and the grooved side wire 2, the side wire 3 and the center wire 4 are twisted and formed by a specific process High-strength steel strands; such as image 3 Shown in figure 2 Based on the product, the epoxy resin 5 is sprayed on it with a specific process, so that the edge wires 2, 3 and the center wire 4 are filled with epoxy resin, and the edges of the edge wires 2, 3 are also coated with a certain thickness of epoxy Resin 5; then remove the epoxy resin 5 in the groove at the required position (meet the space requirements of the embedded fiber and fiber grating sensor 201), implant the fiber and fiber grating sensor 201 into the groove 203, and use epoxy resin 202 encapsulate the optical fiber and fiber grating sensor 201 and use special tooling to protect it.

[0025] The manufacturing method is as follows: a smart filled epoxy-coated ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com