TRT turbine with abrasion-resistant corrosion-resistant nano coating

A nano-coating and turbine technology, applied in the field of TRT turbines, can solve problems such as short service life, low efficiency, and unit failure to operate normally, and achieve the effects of reducing production costs, increasing power generation, and improving defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

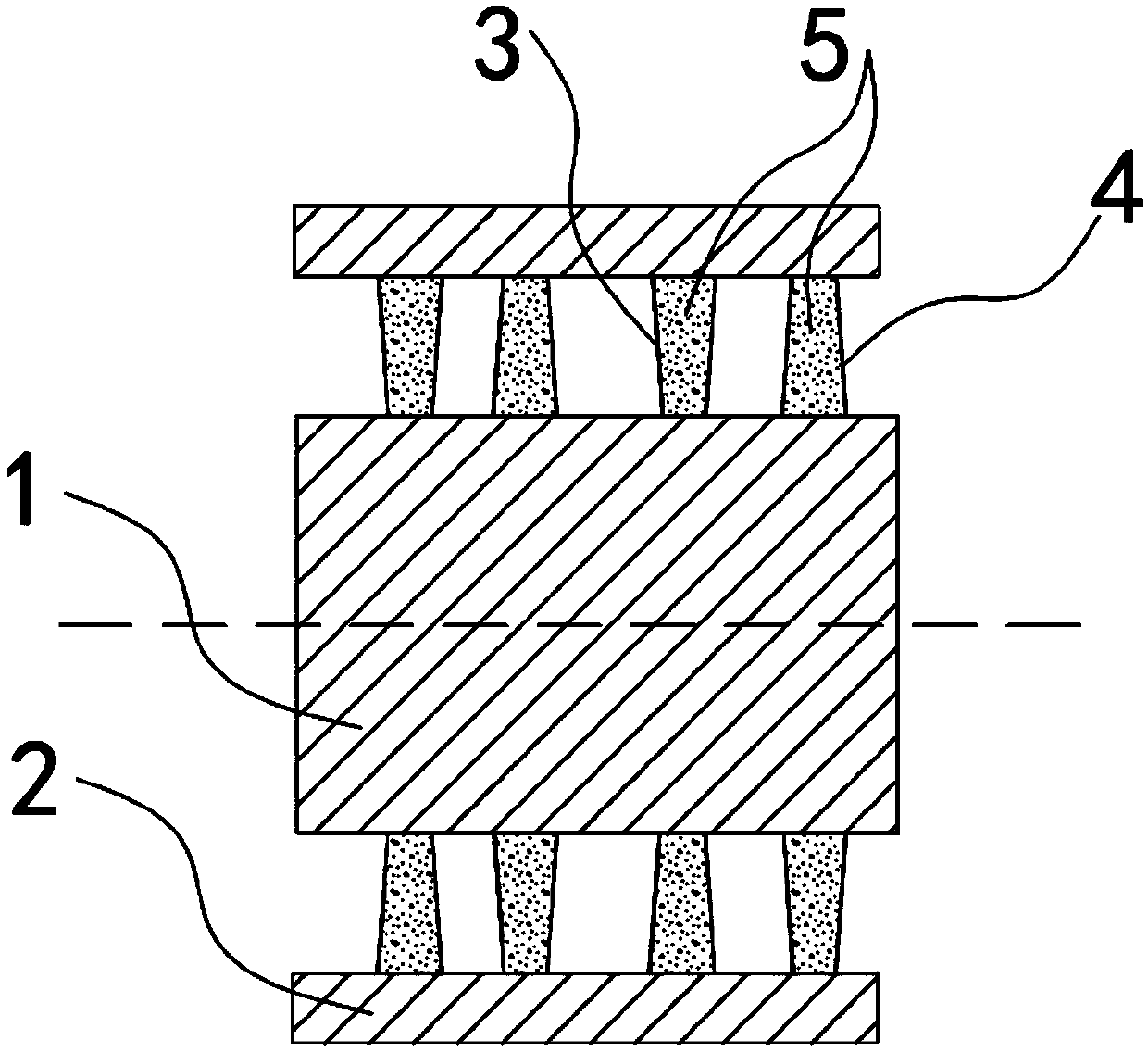

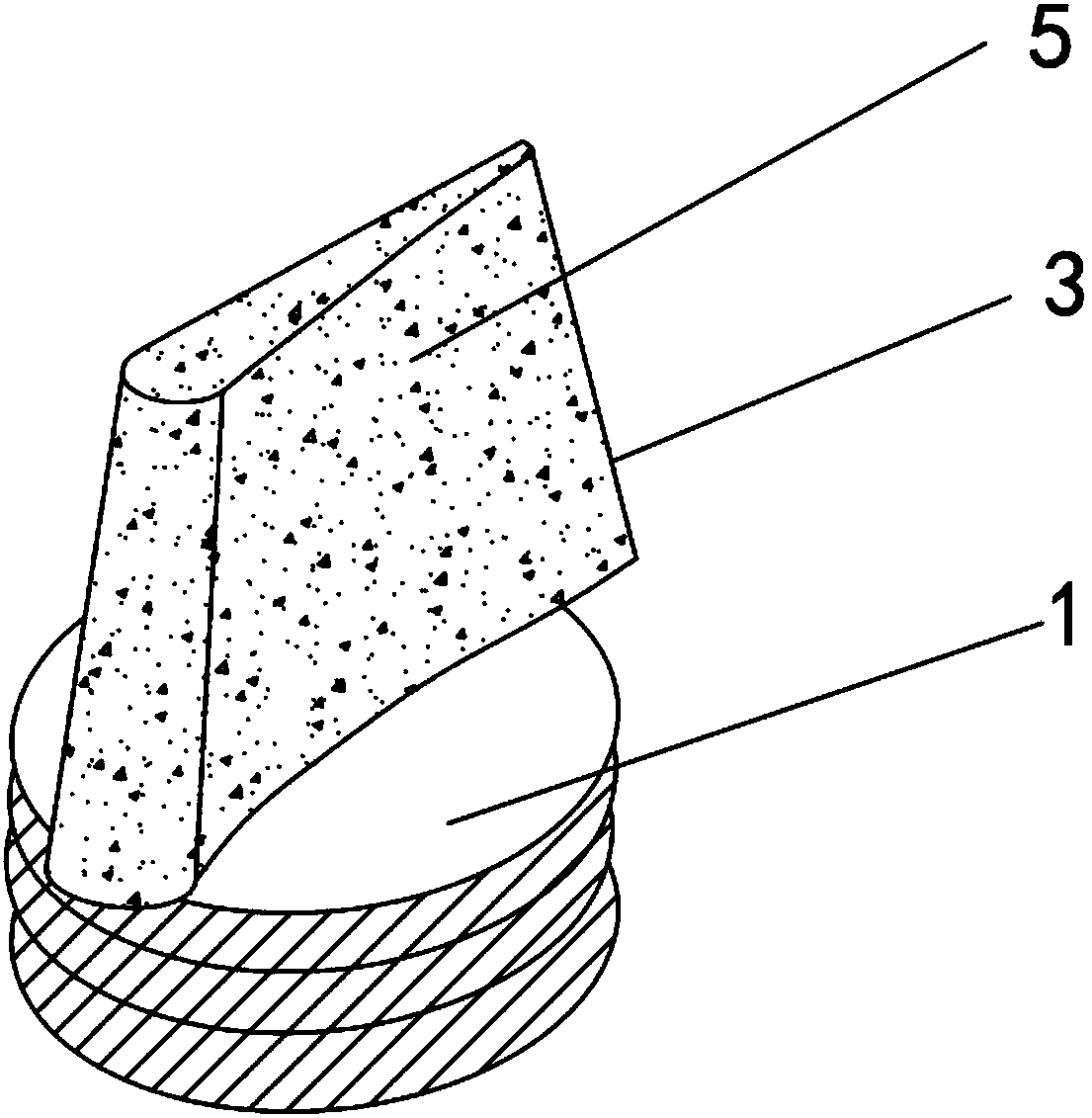

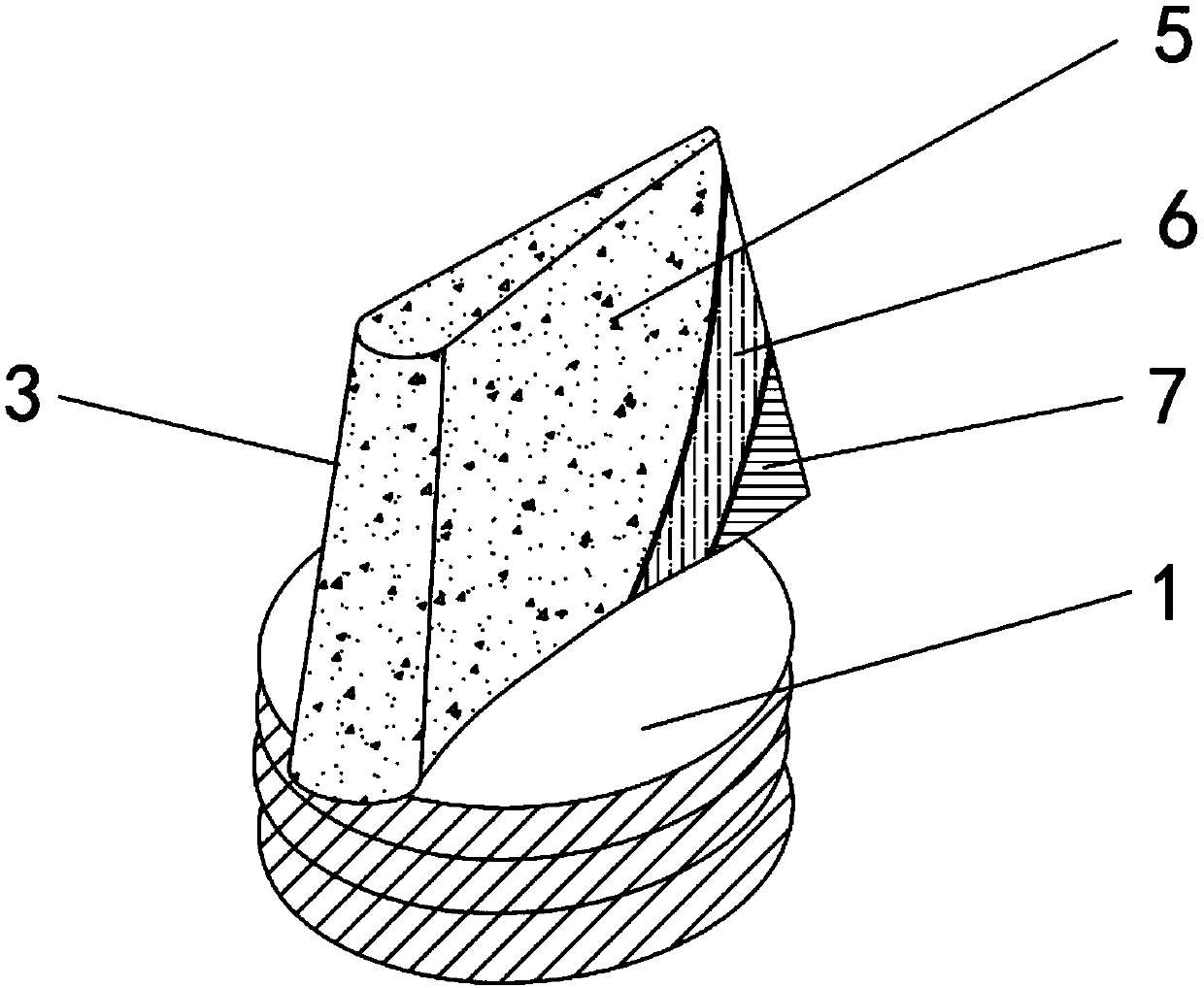

[0032] Such as Figure 1-2 As shown, the embodiment of the present invention provides a TRT turbine with a wear-resistant and corrosion-resistant nano-coating, including moving blades 3 arranged on the main shaft 1 and stationary blades arranged on the casing 2 on the TRT turbine 4. The outer surfaces of the moving blades 3 and the stationary blades 4 on the TRT turbine are provided with a layer of nano-coating protection layer 5. The nano-coating protection layer 5 is a wear-resistant and acid-resistant coating made of nano-ceramic composite materials. Alkali corrosion, high temperature resistant, cavitation resistant nanostructured functional coating. The nano protective layer 5 has good properties of wear resistance, corrosion res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com