High-temperature-resistant furnace wall composite lining with high thermal radiation performance and strong heat insulating performance

A technology with thermal performance and high temperature resistance, which can be used in furnaces, integral linings, lining repairs, etc., and can solve the problems of high production costs and time-consuming and labor-intensive production of composite linings for furnace walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

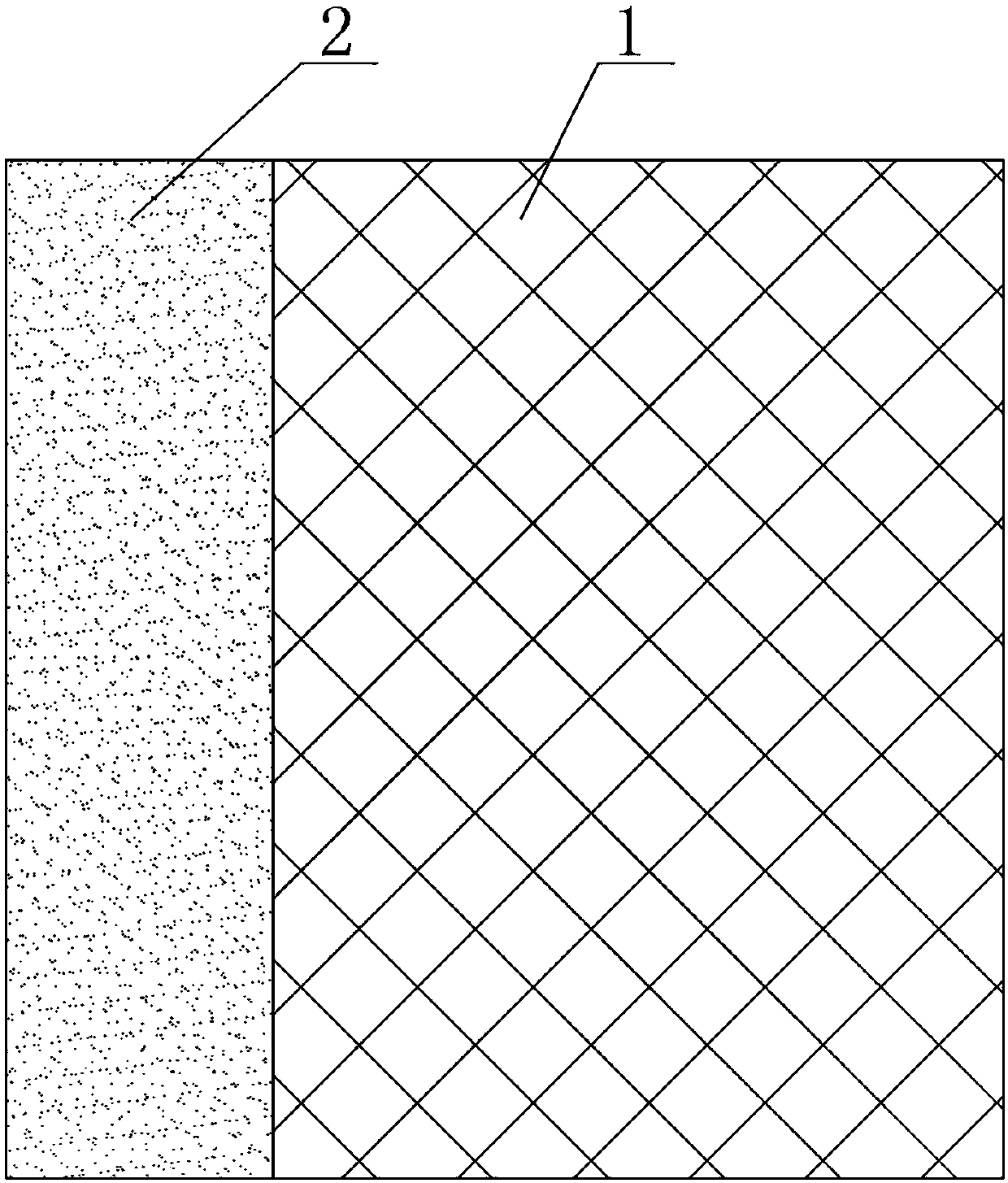

[0016] A high temperature resistant furnace wall composite lining with high heat radiation and strong heat insulation performance, see figure 1 : It includes a ceramic substrate 1, the ceramic substrate 1 has a single-sided radiation layer 2, and the materials of the radiation layer 2 are specifically black metal particles, powder ceramics and curing agent, and the density of the black metal particles is distributed in a certain gradient in the thickness direction of the radiation layer.

[0017] The radiation layer is specifically formed by a sieve-in method and a press molding process again to form a single-sided adhesion layer on one side of the ceramic substrate;

[0018] The radiation layer 2 is specifically a material with strong radiation performance, strong adhesion with ceramic materials, very close expansion coefficient, and high heat resistance; the radiation layer is mixed with black metal powder, powder ceramics, and curing agent, and the density of the black metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap