Parameterization adjustable tail gate rack

A parametric and tailgate technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve data collection that cannot simulate the force of electric struts, inaccurate centroid data, and single testing Problems such as the reciprocating telescopic performance of the electric support rod, to achieve the effect of easy assembly and debugging, convenient structure improvement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

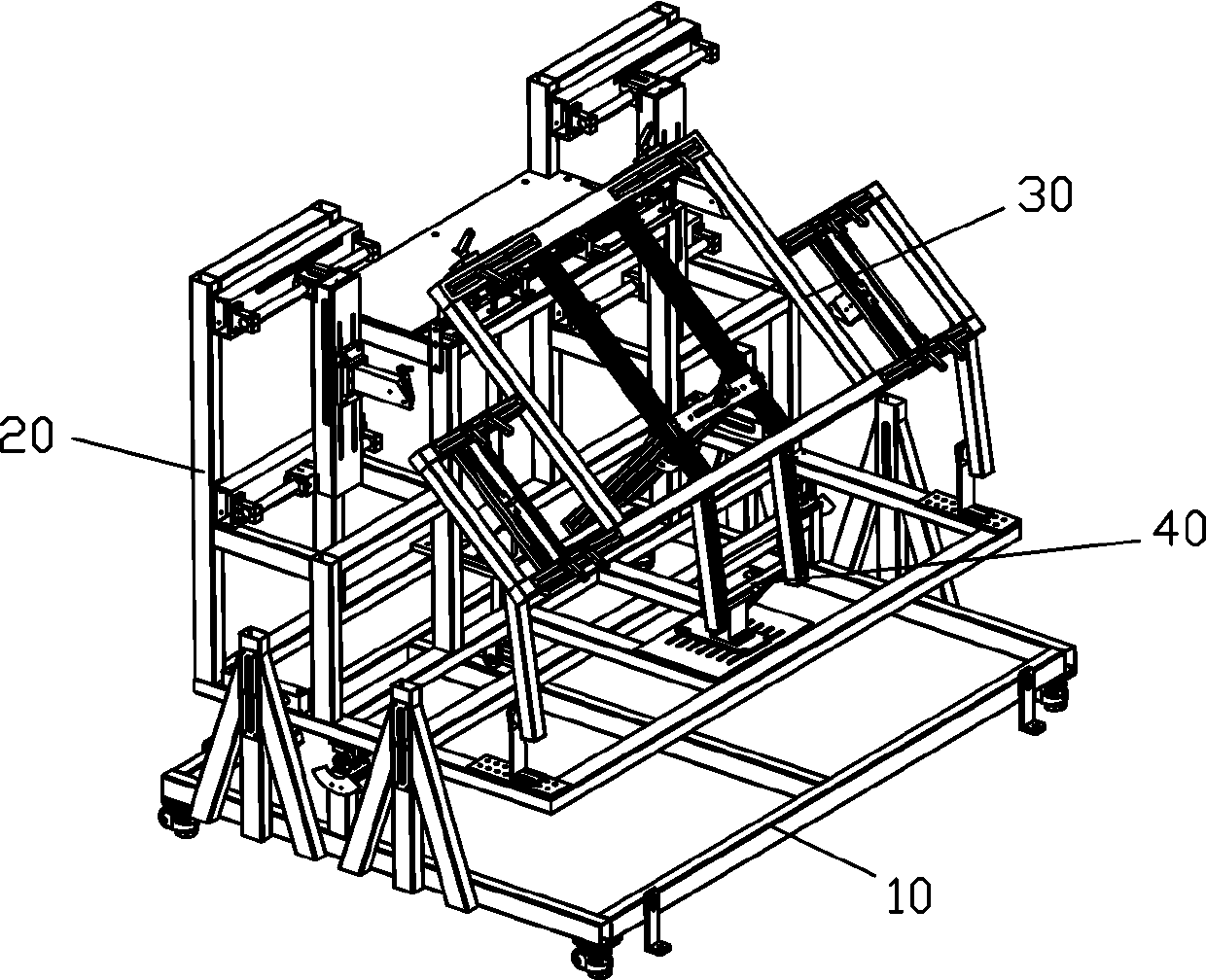

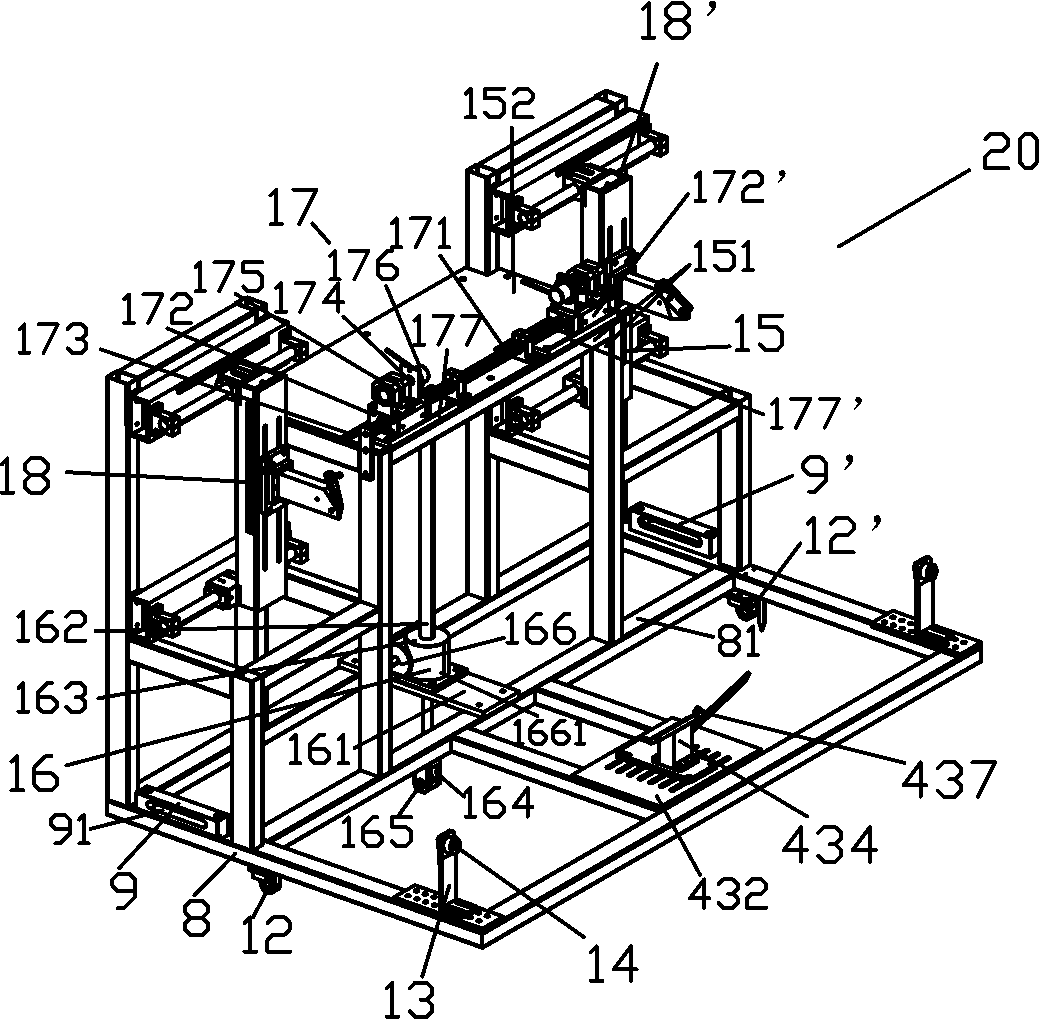

[0025] see Figure 1 to Figure 7 , a parameterized adjustable tailgate stand of the present invention, which includes a base frame 10, an adjustable stand 20, a simulated tailgate frame 30 and a door closing point support assembly 40; wherein,

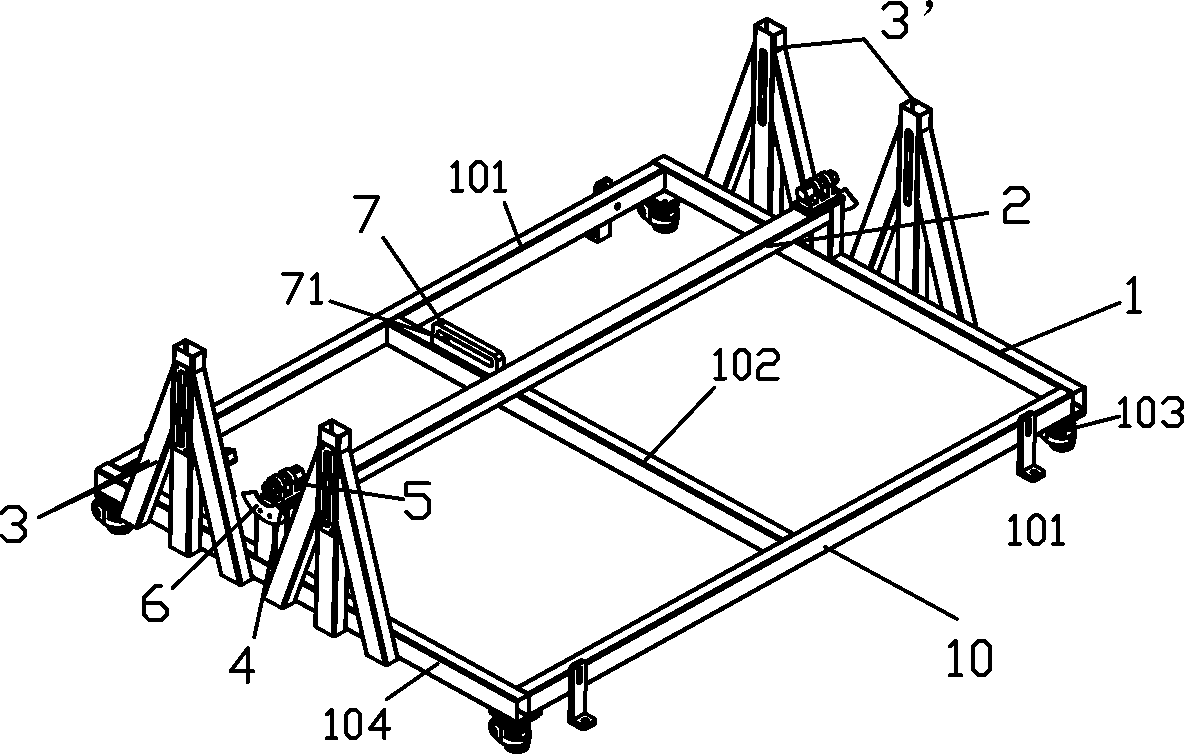

[0026] The base frame 10 includes,

[0027] A base frame 1 is rectangular, with a cross bar 102 in the center of the two long frames 101; feet 103 are provided on the bottom of the four corners of the rectangular frame;

[0028]The support seat 2 is a U-shaped bar structure, and its two ends are connected to one side of the two short frames 104 of the base frame 1;

[0029] Four sets of reinforcing ribs 3, 3' are arranged in twos on the sides of the two short frames 104 of the base frame 1, and are respectively arranged symmetrically on both sides of the support seat 2;

[0030] Two rotating bearings 4 (take the rotating bearing 4 as an example, the same below), are respectively arranged at both ends of the top surface of the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com