Heavy-loaded precise centering adjustment device for thick pinhole collimator

A technology of centering adjustment and collimator, which is applied in the mechanical field to achieve the effect of good self-locking performance, good adjustment feel and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

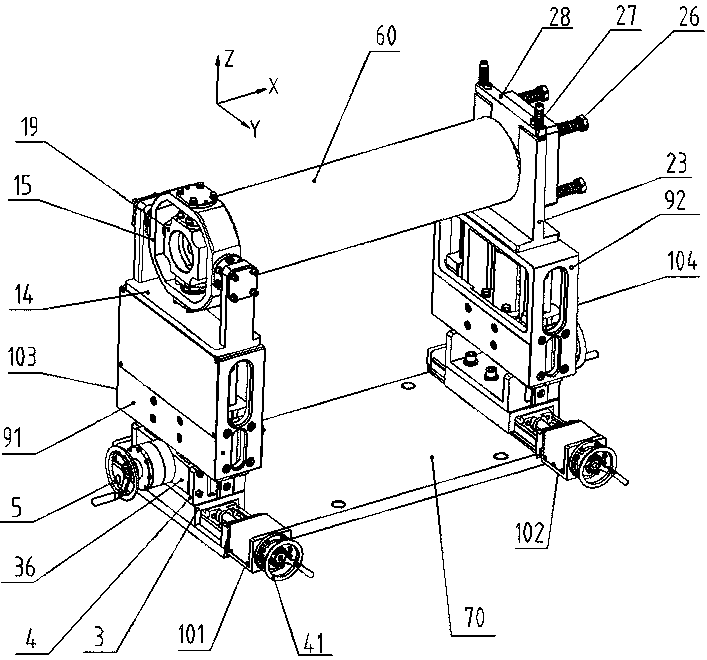

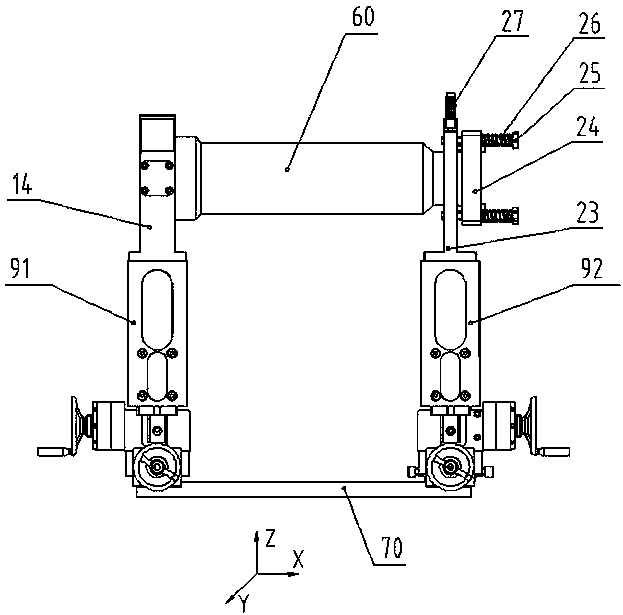

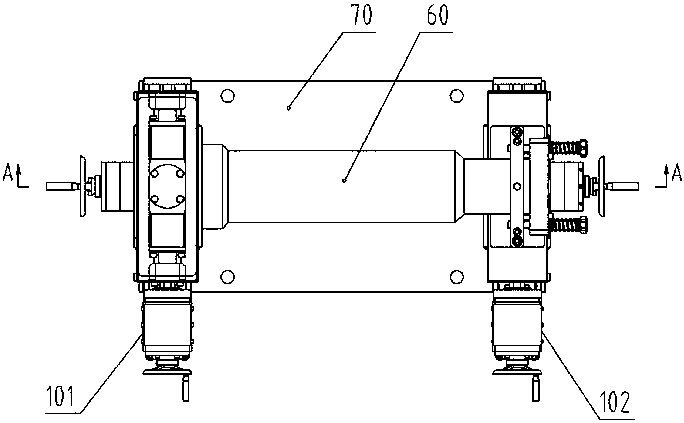

[0051] figure 1 It is a perspective view of the heavy-duty precision centering adjustment device of the thick pinhole collimator of the present invention. figure 2 It is the front view of the heavy-duty precision centering adjustment device structure of the thick pinhole collimator of the present invention, image 3 It is a top view of the heavy-duty precision centering adjustment device of the thick pinhole collimator of the present invention, Figure 4 It is the right view of the heavy-duty precision centering adjustment device of the thick pinhole collimator of the present invention, Figure 5 yes figure 2 The A-A sectional view of Figure 6 yes Figure 4 The B-B sectional view of Figure 7 yes Figure 5 The partial enlarged schematic diagram of D, Figure 8 yes Figure 6 C-C section view of plane, Figure 9 is a perspective view of the inner support frame in the present invention, Figure 10 is a perspective view of the mobile frame in the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com