A Support Vector Machine-Based Correction Method for Measuring Voltage Value of Insulator Inspection Robot

A support vector machine, insulator detection technology, applied in the direction of instruments, computer parts, design optimization/simulation, etc., can solve the problems of changing the electric field distribution of insulator strings, misjudging insulators, reducing partial voltage, etc., to meet practical engineering requirements. Requires, corrects the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples. Those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms are also within the scope of the claims listed in this application.

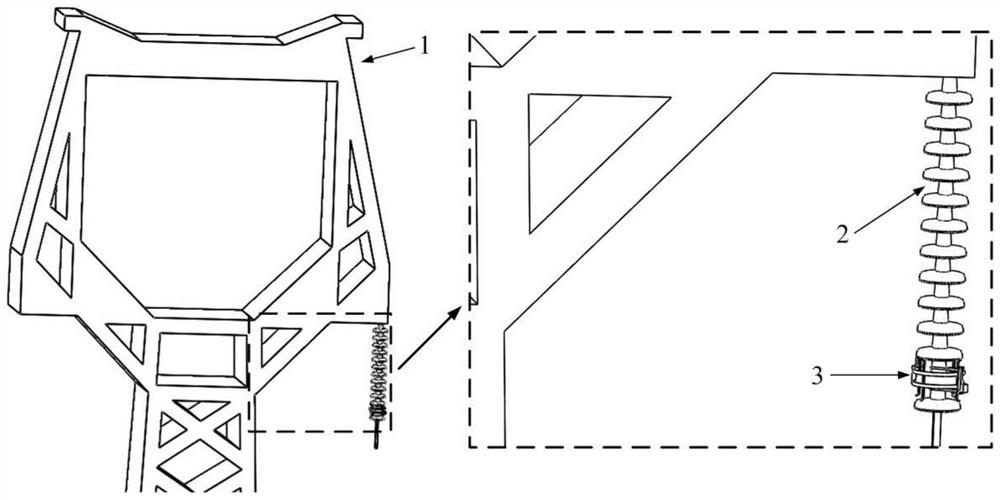

[0023] This example illustrates the implementation of this patent by taking the voltage value correction measured by a 220kV single-circuit linear cat head tower insulator detection robot as an example. The schematic diagram of the insulator robot measurement on the tower is as follows figure 2 As shown in the figure, 1 is a 220kV single-circuit straight cat head tower, 2 is an insulator string and 3 is an insulator detection robot.

[0024] Specific steps are as follows:

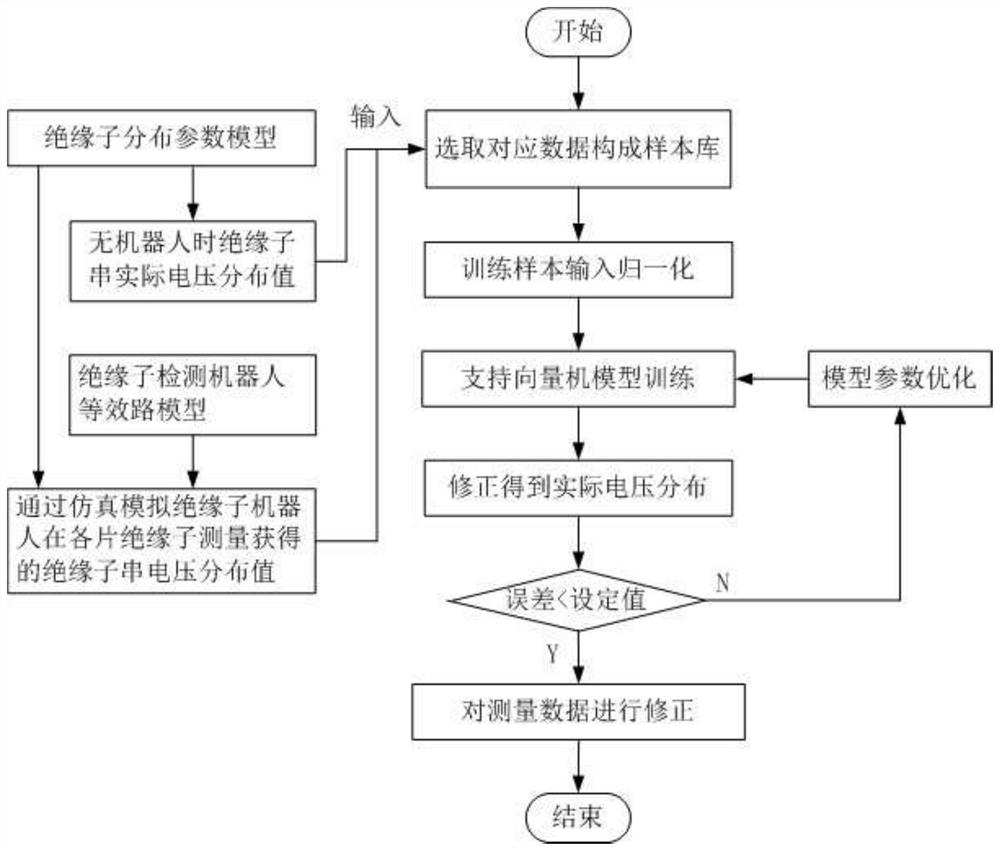

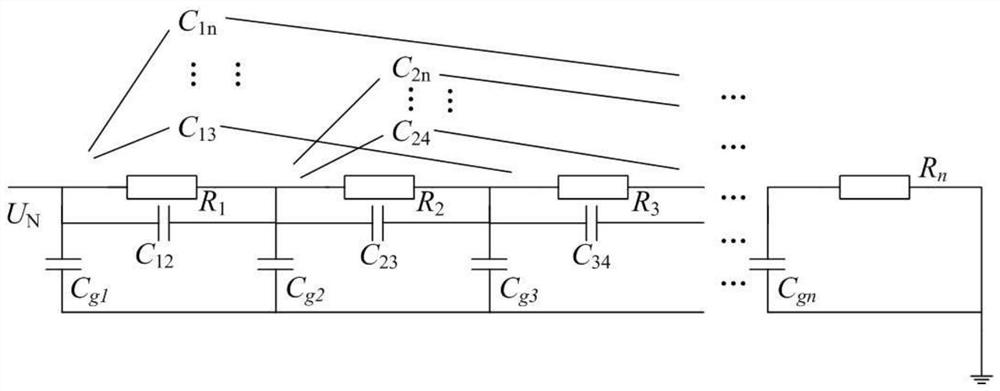

[0025] 1): Firstly, a three-dimensional model is established according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com