Preparation method of silicon substrates on ceramic body

A technology of silicon substrate and ceramic body is applied in the field of preparation of silicon substrate on ceramic body to achieve the effect of simple process method and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

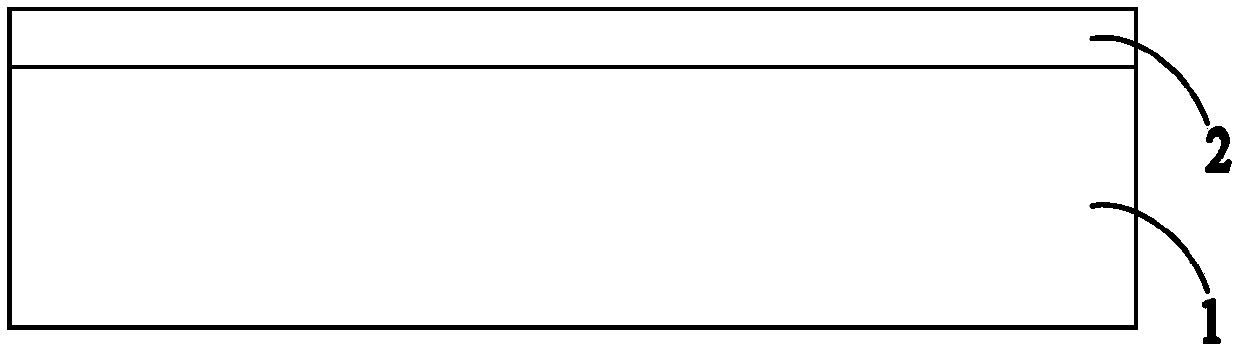

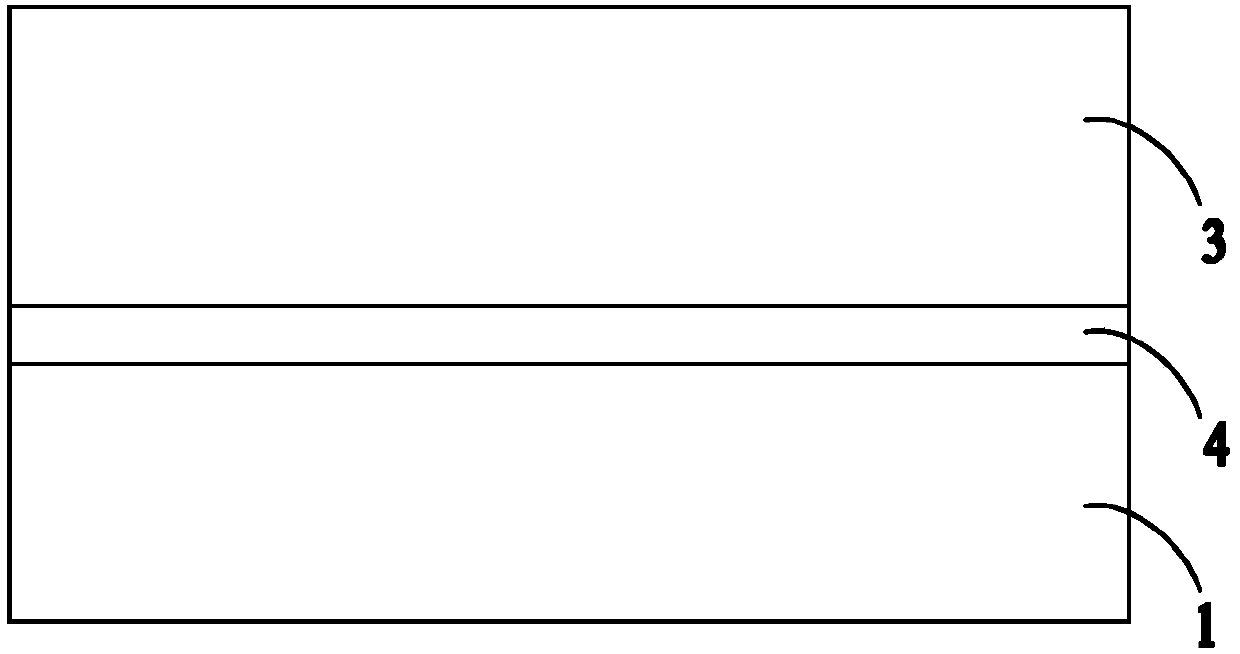

[0024] Such as Figure 1 to Figure 4 Shown: in order to effectively prepare the silicon substrate on the ceramic body, the preparation method of the present invention comprises the following steps:

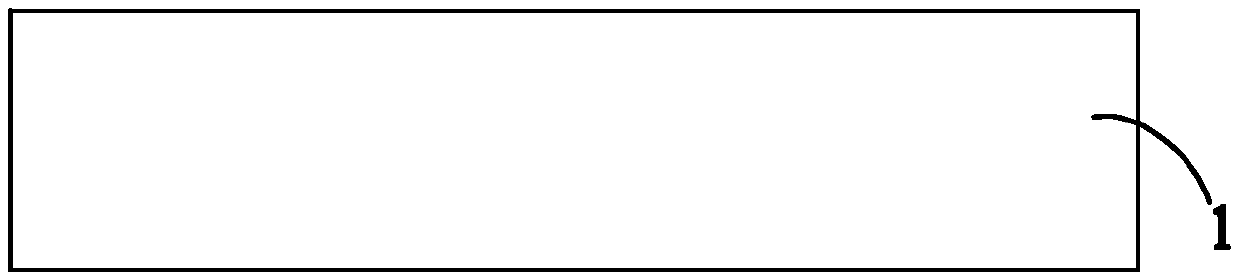

[0025] Step 1, providing the required first silicon substrate 1 and second silicon substrate 3, and performing the cleaning on the first silicon substrate 1 and the second silicon substrate 3;

[0026] Specifically, the first silicon substrate 1 and the second silicon substrate 3 can adopt existing commonly used silicon wafers, such as figure 1 shown. When cleaning the first silicon substrate 1 and the second silicon substrate 3, RCA standard cleaning is adopted. After cleaning the first silicon substrate 1 and the second silicon substrate 3, the first silicon substrate 1 can be effectively removed. , organic substances, metals and particles on the second silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com