DHA microcapsule powder containing lentinan and preparation method thereof

A technology of lentinan and microcapsule powder, which is applied in the field of health care products, can solve the problems that DHA microcapsule powder is not involved, and achieve the effects of guaranteed absorption, simple preparation process and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

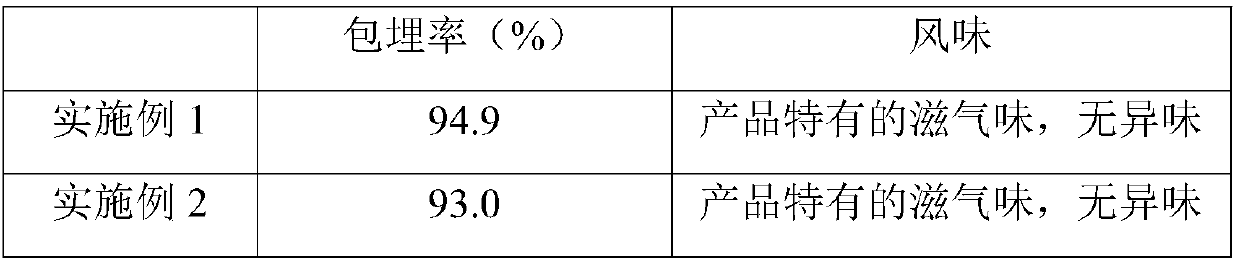

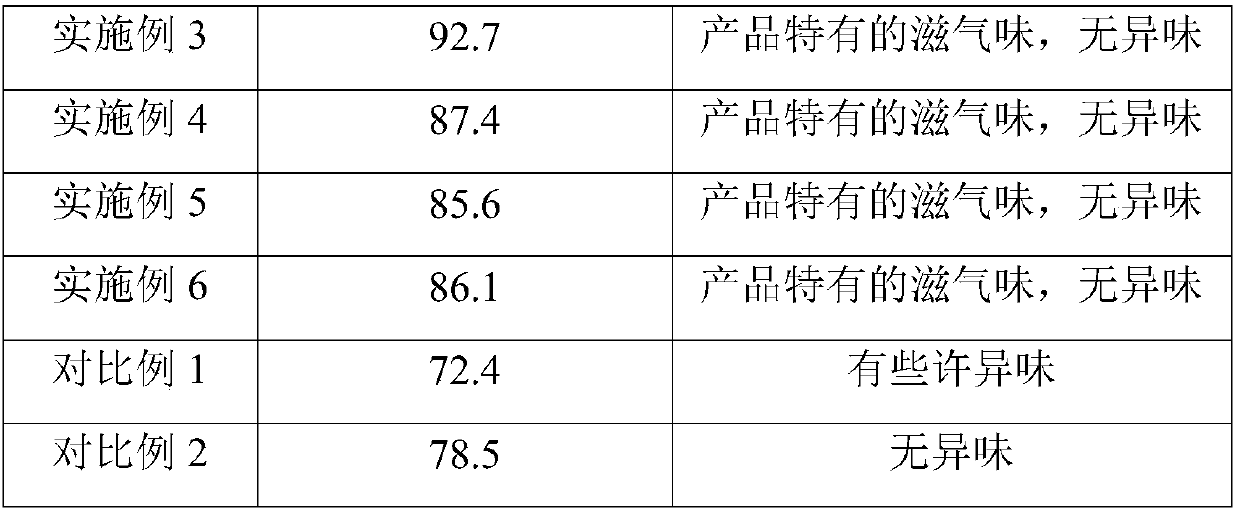

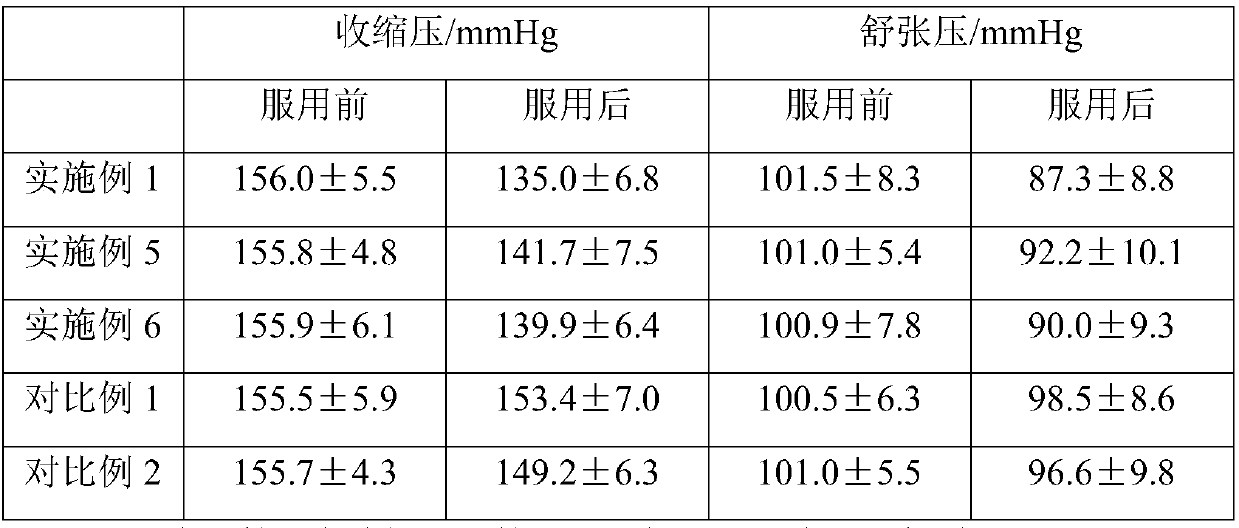

Examples

Embodiment 1

[0025] A DHA microcapsule powder containing lentinan, which is composed of the following raw materials in mass percentage: 38% DHA, 31.5% water-phase main wall material, 28% lentinan, and 2.5% stabilizer; wherein, the ratio of DHA to lentinan is 1.35% .

[0026] The preparation method of the DHA microcapsule powder containing lentinan comprises the following steps:

[0027] S1. Add water to the water-phase main wall material at a ratio of 1:2.5, heat to 60-65°C, stir for 30 minutes, add the stabilizer, and continue stirring for 30 minutes to prepare the wall material;

[0028] S2. Mix the DHA and lentinan with the wall material obtained in step S1, and homogenize and emulsify under high pressure into a nanoemulsion with a particle size of 100-200 nm, with a homogenization pressure of 35-40 MPa;

[0029] S3. The nanoemulsion is spray-dried, the feed temperature is 60-70° C., the air inlet temperature is 165-175° C., and the air outlet temperature is 65° C. to prepare the DHA m...

Embodiment 2

[0031] A DHA microcapsule powder containing lentinan, which is composed of the following raw materials in mass percentage: 40% DHA, 28.4% water-phase main wall material, 28.6% lentinan, and 3% stabilizer; wherein, the ratio of DHA to lentinan is 1.4% .

[0032] The preparation method of the DHA microcapsule powder containing lentinan is the same as in Example 1.

Embodiment 3

[0034] A DHA microcapsule powder containing lentinan, which is composed of the following raw materials in mass percentage: 35% DHA, 34.4% water-phase main wall material, 29.1% lentinan, and 1.5% stabilizer; wherein, the ratio of DHA to lentinan is 1.2% .

[0035] The preparation method of the DHA microcapsule powder containing lentinan is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diastolic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com