Process for removing alpha layer of titanium alloy of aero-engine blower internal cartridge receiver unit

An aero-engine and titanium alloy technology is applied in the field of removing the titanium alloy α layer of the inner casing unit of the aero-engine fan. and other problems, to achieve the effect of low production cost, avoiding over-corrosion and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

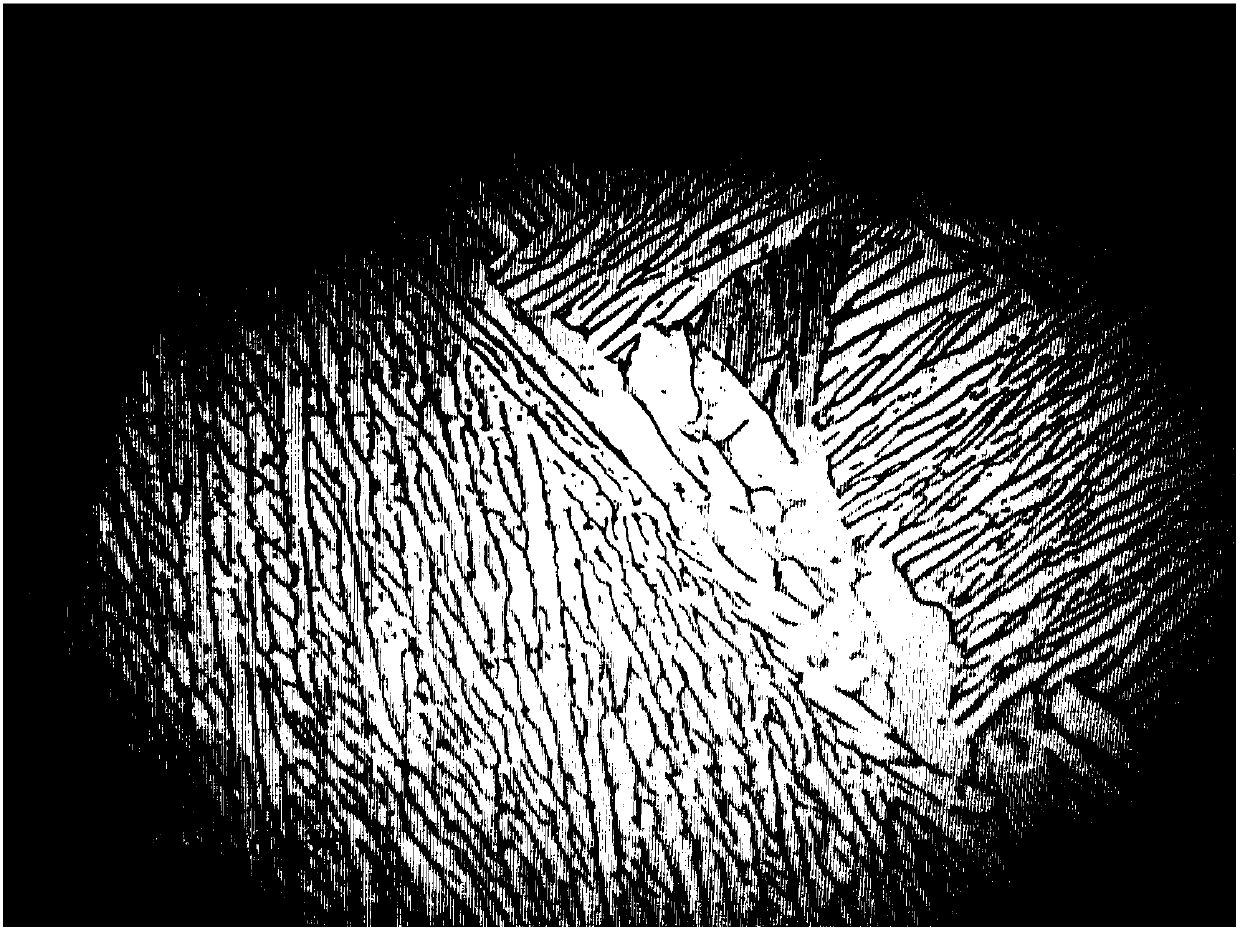

[0033] It is calculated that the thickness of the alpha layer of the sample with the same material as the casing unit of the aero-engine fan and heat treatment in the same state is 18 microns, and the metallographic photos are as follows figure 2 shown.

[0034] (1) Alkaline cleaning oil stains: immerse the casing unit of the aero-engine fan in an alkaline washing solution and shake and wash at 30°C for 15 minutes to remove oil stains on the workpiece surface. The alkaline washing solution is Biogenic SE374 produced by RMC The volume concentration of the industrial cleaning agent prepared with water is 12vol% alkaline lotion;

[0035] (2) Clean the alkaline lotion: remove the casing unit of the aero-engine fan from the alkaline lotion, drain the alkaline lotion in the inner cavity of the casing, immerse it in clean water through the hanging device and shake it for 2 minutes to clean the surface of the workpiece. alkaline washing solution;

[0036] (3) Determine the pickling...

Embodiment 2

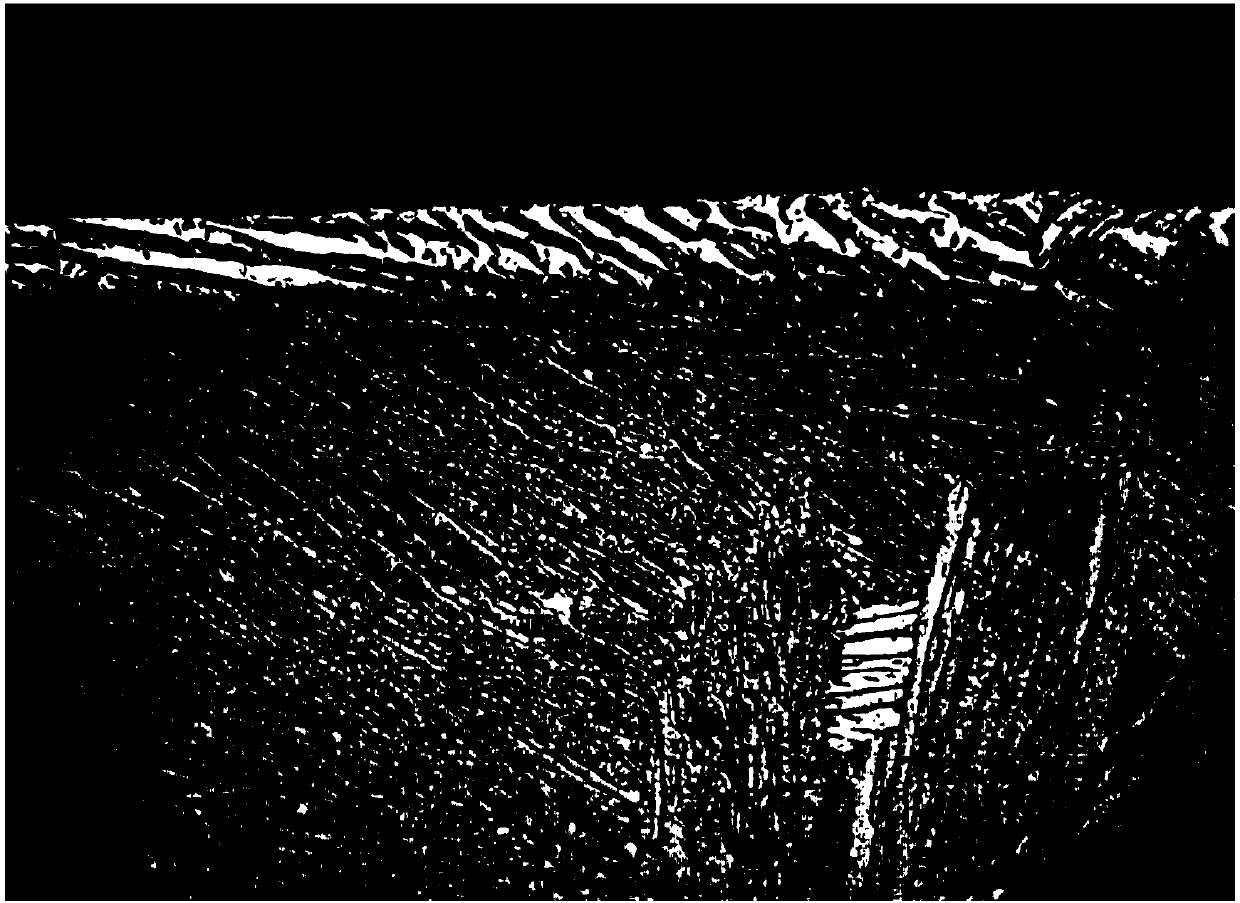

[0042] It is calculated that the thickness of the α layer of the sample with the same material as the casing unit in the fan of the aero-engine and heat-treated in the same state is 16 microns, and the metallographic photos are as follows image 3 shown.

[0043] (1) Alkali cleaning oil stains: immerse the casing unit of the aero-engine fan in an alkaline washing liquid and shake it at 35°C for 10 minutes to remove the oil stains on the surface of the workpiece. The alkaline washing liquid is Biogenic SE374 produced by RMC The volume concentration of the industrial cleaning agent prepared with water is 25vol% alkaline lotion;

[0044] (2) Clean the alkaline lotion: remove the casing unit of the aero-engine fan from the alkaline lotion, drain the alkaline lotion in the inner cavity of the casing, immerse it in clean water through the hanging device and shake it for 5 minutes to clean the surface of the workpiece. alkaline washing solution;

[0045] (3) Determine the pickling ra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap