Monocrystalline silicon seed crystal splicing method

A monocrystalline silicon and seed crystal technology, which is applied in the field of photovoltaic solar cell manufacturing, can solve the problem of large gaps in monocrystalline silicon seed crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

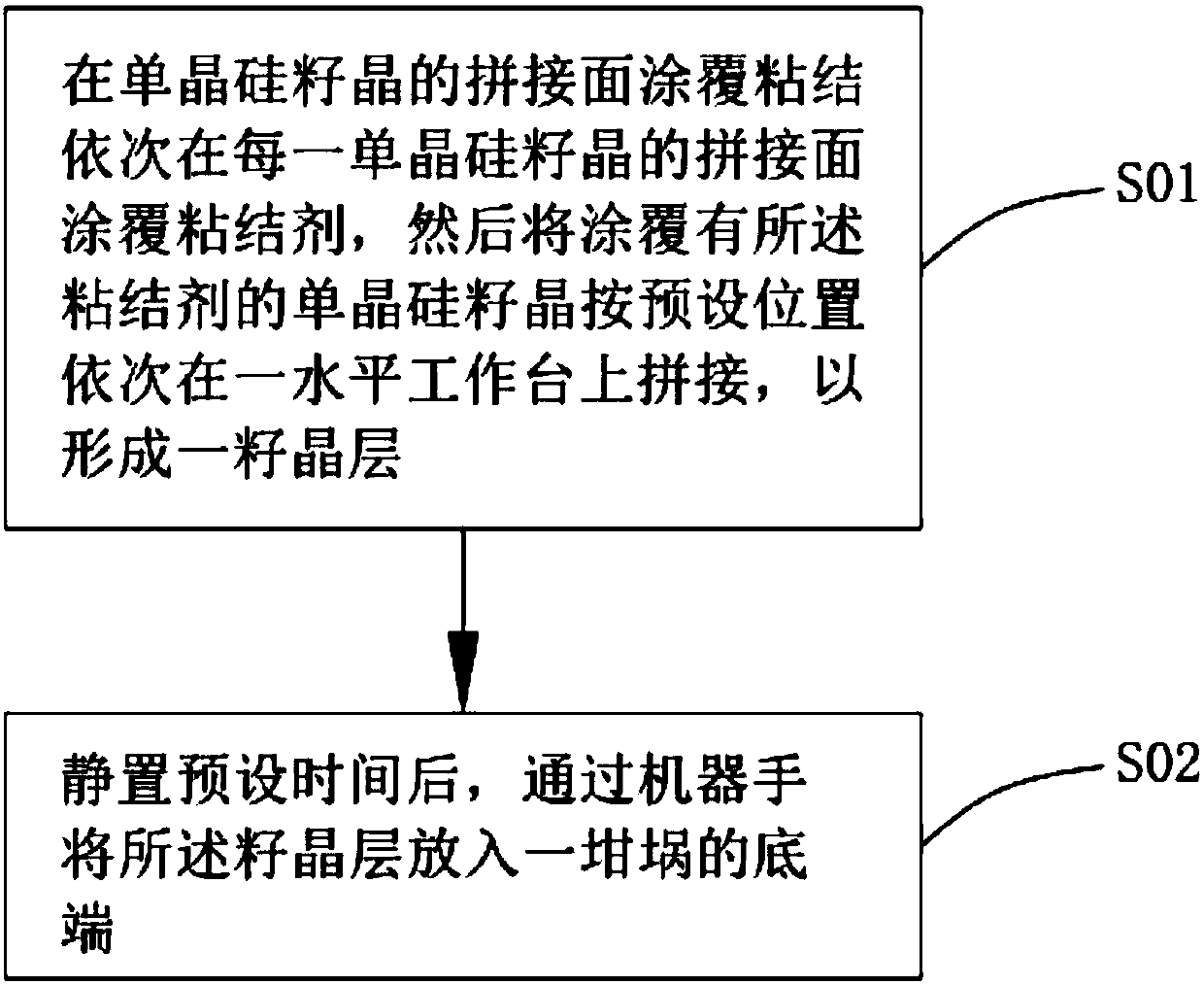

[0027] see Figure 1 to Figure 3 A method for splicing single crystal silicon seed crystals according to the first embodiment of the present invention includes step S01 and step S02.

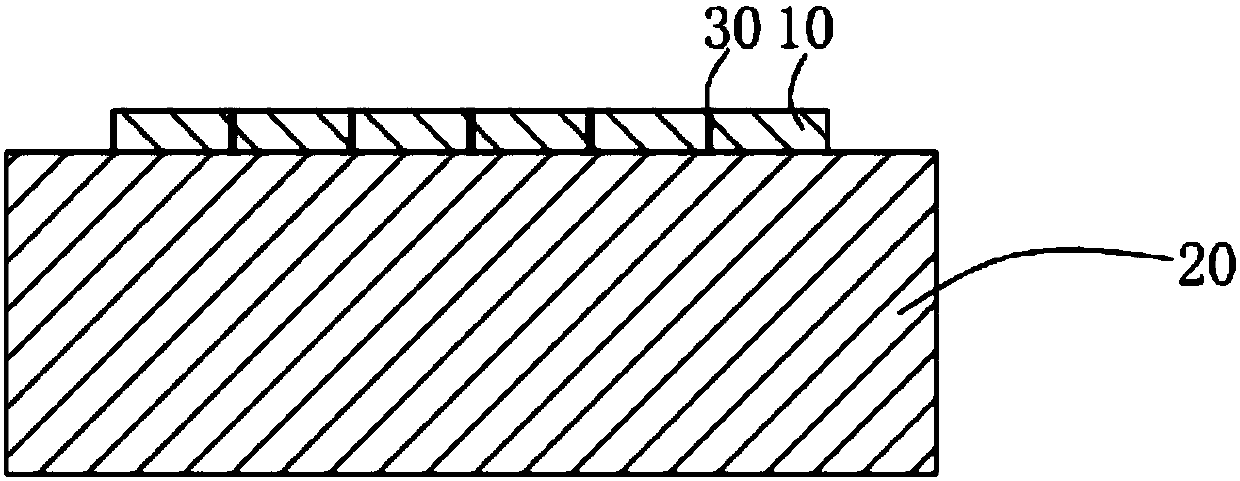

[0028] Step S01, coating the bonding agent on the splicing surface of each silicon single crystal seed crystal 10 in sequence, and then placing the single crystal silicon seed crystal 10 coated with the adhesive 30 on a surface roughness Splice on a horizontal workbench 20 smaller than 0.2 mm to form a seed layer 100 .

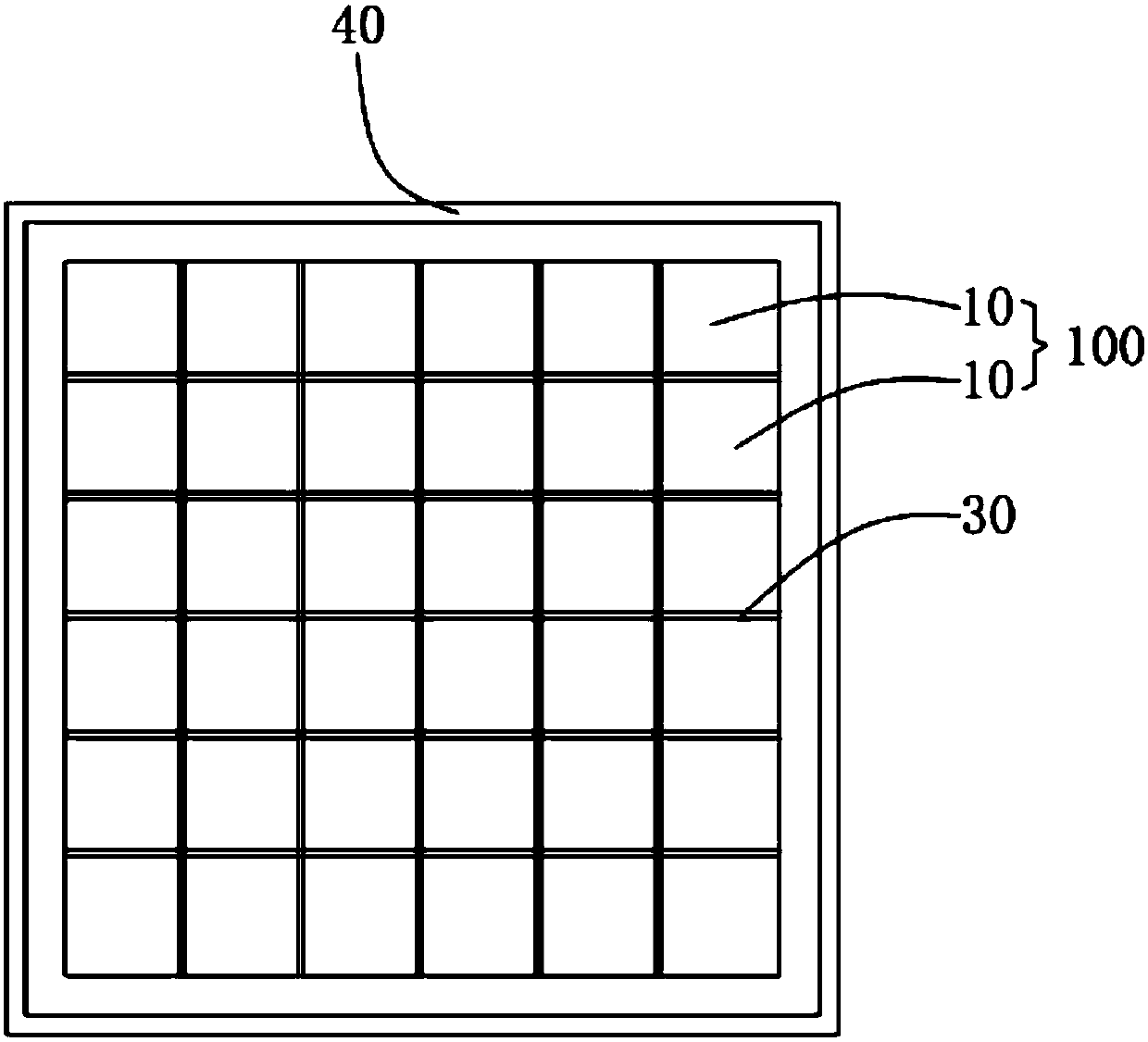

[0029] Specifically, in this embodiment, 36 single-crystal silicon seed crystals 10 are selected in advance, and the height difference between every two single-crystal silicon seed crystals is less than 1mm, and these 36 single-crystal silicon seed crystals 10 are sequentially placed Coat the bonding agent 30 on the splicing surface, and sequentially splice 36 single crystal silicon seed crystals 10 in a 6×6 manner to form a seed crystal layer 100 .

[0030] It can be understo...

Embodiment 2

[0042] A method for splicing single crystal silicon seed crystals provided by the second embodiment of the present invention includes step S11 and step S12.

[0043] Step S11, selecting 49 single crystal silicon seed crystals 10, coating the bonding agent on the splicing surface of each single crystal silicon seed crystal 10 in turn, and then coating the single crystal silicon seed crystals 10 coated with the adhesive 30 49 single crystal silicon seed crystals 10 were spliced sequentially in a 7×7 manner on a horizontal workbench 20 with a surface roughness less than 0.2 mm to form a seed crystal layer 100 .

[0044] Specifically, in this embodiment, the main components of the binder 30 include a mixture of silica sol and ceramic binder, and the mixing ratio of silica sol and ceramic binder is 1:1.

[0045] Step S12, after standing still for 3600s, put the seed crystal layer 100 into the bottom end of the crucible 40 by the robot.

Embodiment 3

[0047] A method for splicing single crystal silicon seed crystals provided by the third embodiment of the present invention includes step S21 and step S22.

[0048] Step S21, select 25 single crystal silicon seed crystals 10, apply adhesive on the splicing surface of each single crystal silicon seed crystal 10 in turn, and then place the single crystal silicon seed crystals 10 coated with the adhesive 30 25 single crystal silicon seed crystals 10 are spliced sequentially in a 5×5 manner on a horizontal workbench 20 with a surface roughness less than 0.2 mm to form a seed crystal layer 100 .

[0049] Specifically, in this embodiment, the main components of the binder 30 include a mixture of silica sol and ceramic binder, and the mixing ratio of silica sol and ceramic binder is 2:1.

[0050] Step S22, after standing still for 1800s, put the seed crystal layer 100 into the bottom end of the crucible 40 by robot.

[0051] Combining with Example 1, Example 2, and Example 3, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com