Method for preparing high-strength corrugated base paper from straws

A corrugated base paper, high-strength technology, applied in papermaking, paper machines, textiles and papermaking, etc., can solve the problems affecting the strength performance of corrugated base paper, poor bonding force between fibers, etc., achieve rich raw materials, increase strength, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

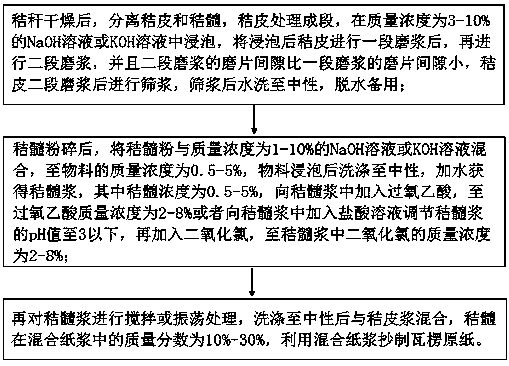

Method used

Image

Examples

Embodiment 1

[0042] High-strength corrugated base paper was prepared from corn stalks. Dry the corn stalks in the sun and remove the leaves, separate the husks and straw pith, process the husks into small pieces of 0.5cm×2cm, soak them in 3% NaOH solution for 4 hours, the ratio of the volume of the solution to the mass of the husks is 7:1 , the alkali-treated straw is subjected to two-stage refining, the first-stage refiner disc gap is 0.2mm, and then the second-stage refiner is carried out, the refiner disc gap is 0.02mm, and the two-stage refiner is screened after the two-stage refining pulp, the sieve aperture is 0.3mm, the straw pulp that is sieved is washed to neutrality, and dehydrated for subsequent use;

[0043] After crushing the straw, pass through a 20-mesh sieve, mix the straw powder with 4% NaOH solution until the material concentration is 2%, soak at 35°C for 5 hours, wash with water until neutral, add water until the mass fraction of straw is 1.5 %, add peracetic acid until...

Embodiment 2

[0046] High-strength corrugated base paper was prepared from corn stalks. Dry the corn stalks in the sun and remove the leaves, then separate the husks and pith. The husks are processed into small pieces of 0.4cm×3cm, soaked in 5% NaOH solution for 6 hours, and the ratio of the volume of the solution to the mass of the husk is 5:1. , the alkali-treated straw is subjected to two-stage refining, the first-stage refiner disc gap is 0.4mm, and then the second-stage refiner is carried out, the refiner disc gap is 0.03mm, and the two-stage refiner is screened after the two-stage refining pulp, the sieve aperture is 0.35mm, and the straw pulp that is sieved is washed to neutrality, dehydrated for subsequent use;

[0047] After crushing the straw, pass through a 20-mesh sieve, mix the straw powder with 1% NaOH solution to a material concentration of 4%, soak at 20°C for 2 hours, wash with water until neutral, add water until the mass fraction of the straw is 1 %, add peracetic acid u...

Embodiment 3

[0050] High-strength corrugated base paper was prepared from corn stalks. After the corn stalks are air-dried and defoliated, the husks and pith are separated. The husks are processed into small sections of 0.3cm×5cm and soaked in 6% NaOH solution for 10 hours. The ratio of the volume of the solution to the mass of the husks is 8:1. The alkali-treated straw is subjected to two-stage refining, the first-stage refiner has a grinding gap of 0.5 mm, and then the second-stage refining is performed, and the refining machine gap is 0.04 mm, and the pulp is sieved after the two-stage refining , the sieve aperture is 0.4mm, the straw pulp that sieves is washed to neutrality, and dehydrated for subsequent use;

[0051] After crushing the straw, pass through a 20-mesh sieve, mix the straw powder with 5% NaOH solution until the material concentration is 3%, soak at 40°C for 10 hours, wash with water until neutral, add water until the mass fraction of straw is 2 %, add peracetic acid unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com