Bridge-cutoff aluminum alloy energy-saving window

An aluminum alloy and energy-saving window technology, which is applied in windows/doors, door/window accessories, door/window applications, etc., can solve the problem of thermal insulation performance comparison, aging resistance and wind pressure resistance of plastic steel profiles inferior to broken bridge aluminum alloys Profiles and other issues, to achieve the effect of slowing down heat conduction, obvious heat insulation effect, and reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

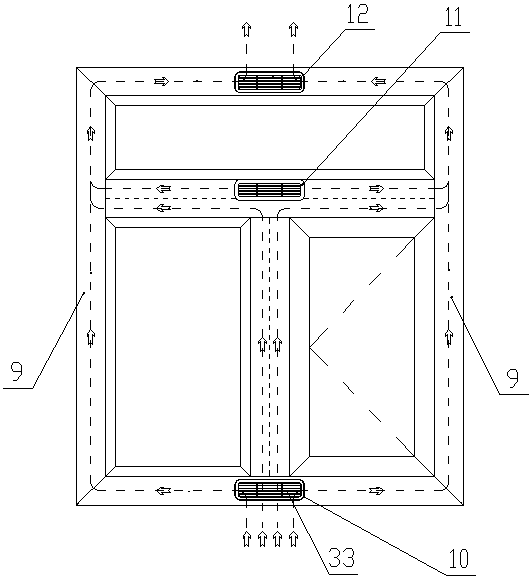

[0030] figure 2 The direction indicated by the middle arrow is the airflow direction at this place.

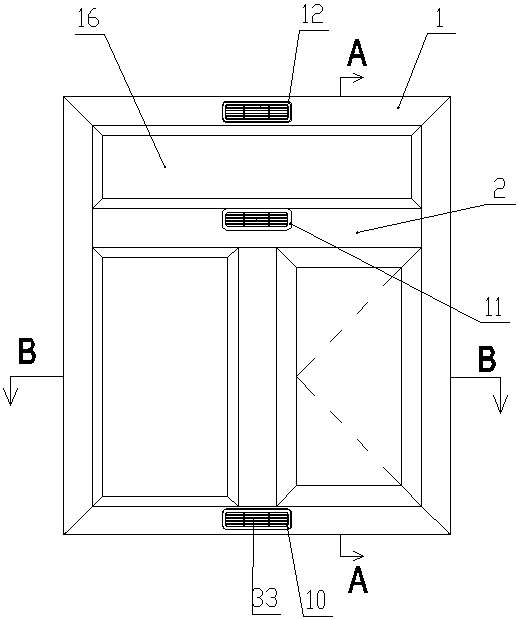

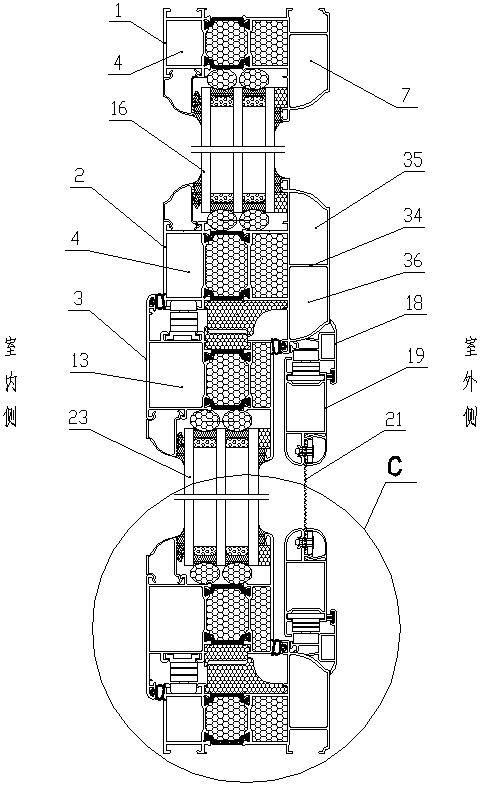

[0031] Such as Figure 1 to Figure 6 As shown, the broken bridge aluminum alloy energy-saving window of the present invention includes a window frame and an opening window, the window frame includes a frame profile 1 and a middle frame profile 2, and the opening window includes a sash profile 3,

[0032] The frame profile 1 and the middle frame profile 2 both have a four-cavity structure, and the four-cavity structure includes a first chamber 4, a second chamber 5, a third chamber 6 and a fourth chamber arranged in sequence from the inside to the outside. The chamber 7, the second chamber 5 and the third chamber 6 are filled with polyurethane foam material 8, which can eliminate air heat transfer. The fourth chamber 7 is also known as the heat dissipation ventilation channel. The two end to end are connected to form a rectangular structure, the fourth chamber 7 in each fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com