High-space-utilization power electronic capacitor

A technology of power electronics and capacitors, applied in the field of high space utilization power electronic capacitors, can solve the problems of not being able to increase the capacity, increase the weight and cost of power electronic capacitors, and reduce the space utilization of power electronic capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

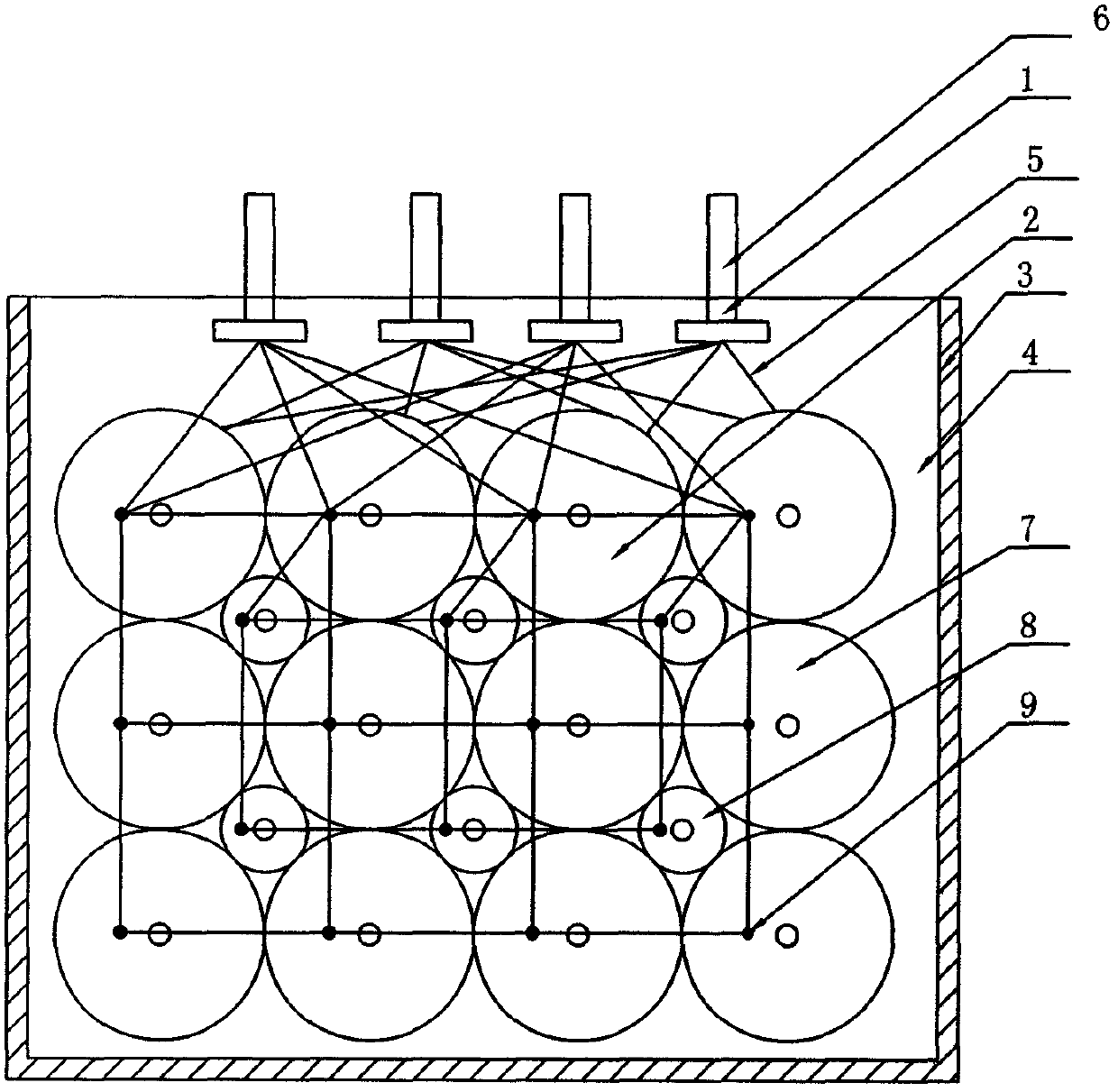

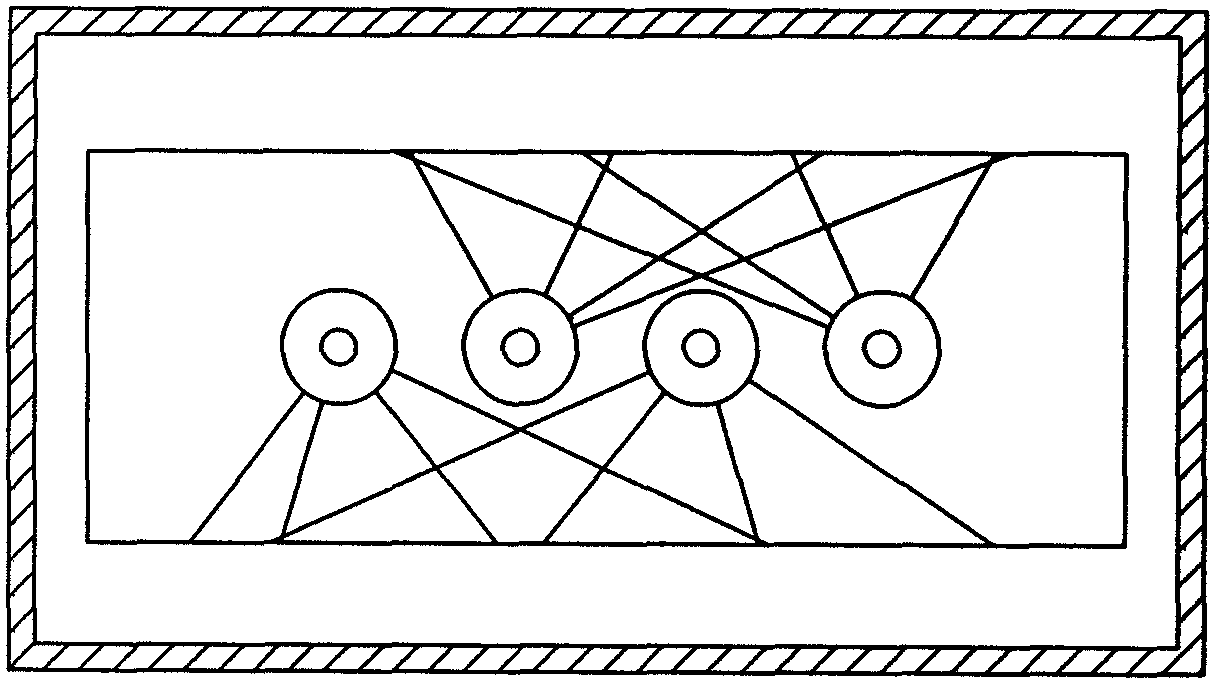

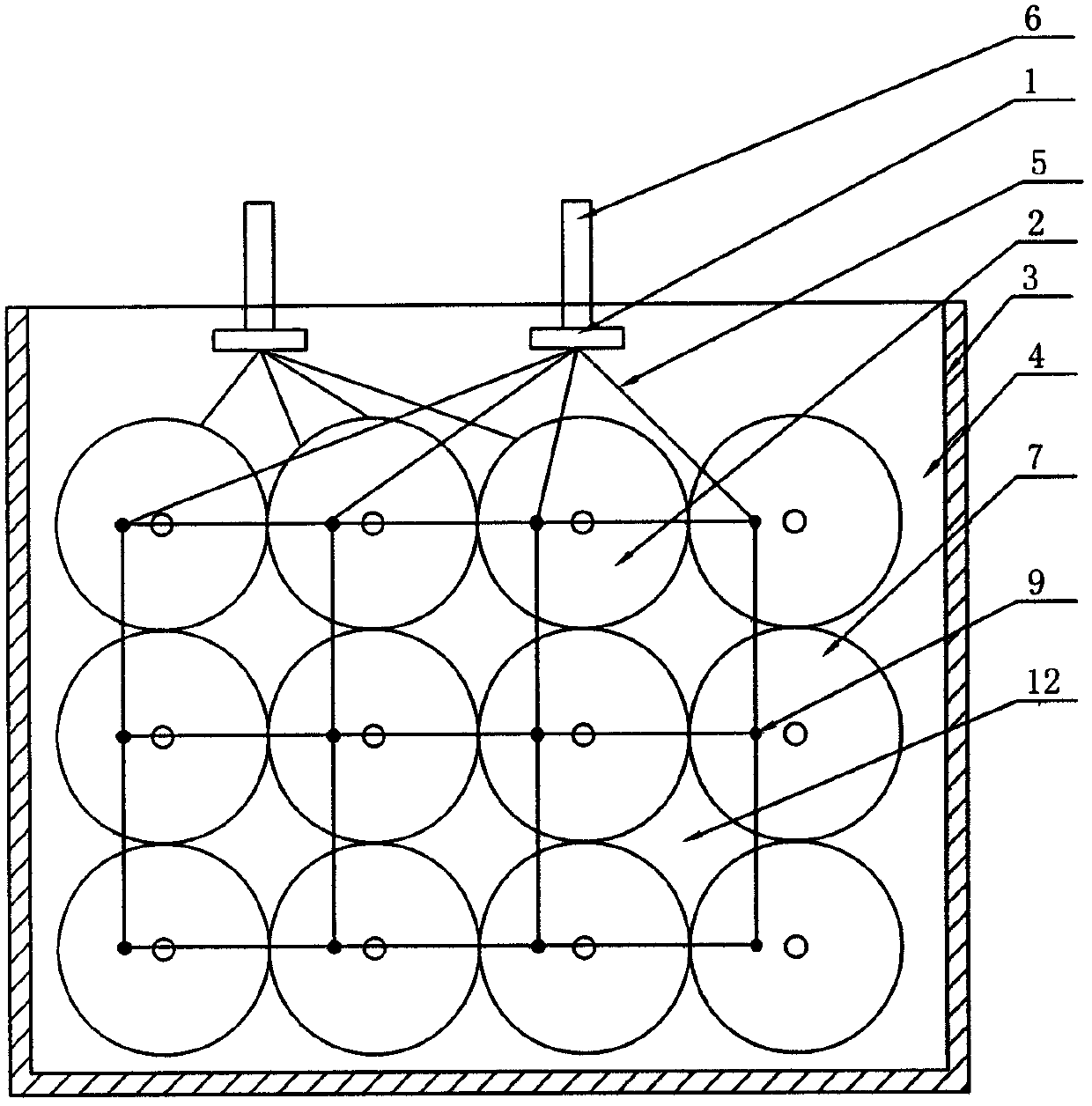

[0018] The high space utilization power electronic capacitor of the embodiment of the present invention is in such as image 3 with Figure 4 The power electronic capacitor shown in the prior art is improved on the basis of the structure, mainly by squeezing 6 small cylindrical capacitor cores into the space 12 between its 12 cylindrical large capacitor cores 7, specifically structured as figure 1 with figure 2 Shown:

[0019] ——The capacitor core assembly 2 located in the inner cavity of the housing 3 is composed of 12 cylindrical large capacitor cores 7 and 6 small cylindrical capacitor cores 8 that are also cylindrical. 12 large capacitor cores 7 are closely distributed into 3 horizontal rows and 4 vertical columns, and 6 small capacitor cores 8 are squeezed into the space between the large capacitor cores 7 . The gold-sprayed layers of the front and rear faces of the large and small capacitor cores are welded at the soldering point 9 with wires distributed in a rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com