Fan-shaped antenna packaging structure and preparation method thereof

A technology of packaging structure and antenna structure, which is applied in the direction of antenna support/mounting device, antenna, loop antenna, etc., can solve the problem of enlarging the area of the packaging structure, achieve the effect of small line width, increase gain, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

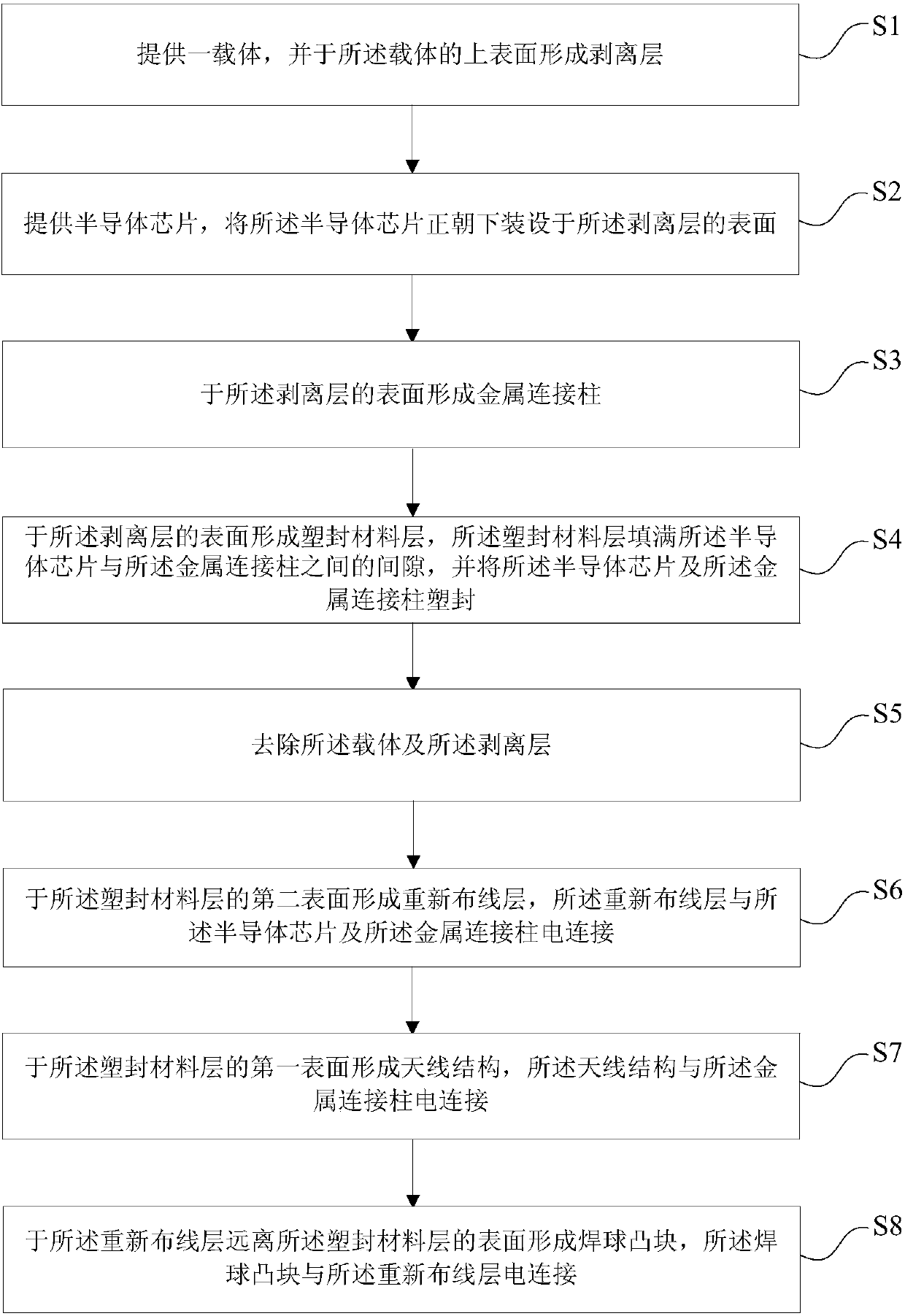

[0077] see figure 1 , the present invention provides a method for preparing a fan-out antenna package structure, the method for preparing a fan-out antenna package structure includes the following steps:

[0078] 1) providing a carrier, and forming a release layer on the upper surface of the carrier;

[0079] 2) Provide a semiconductor chip, and install the semiconductor chip on the surface of the peeling layer facing down;

[0080] 3) forming a metal connection column on the surface of the peeling layer;

[0081] 4) forming a plastic sealing material layer on the surface of the peeling layer, the plastic sealing material layer fills the gap between the semiconductor chip and the metal connecting column, and plastic seals the semiconductor chip and the metal connecting column; The molding material layer includes opposite first surfaces and second surfaces, the second surface of the molding material layer is in contact with the release layer, and the first surface of the mold...

Embodiment 2

[0145] read on Figure 13 and Figure 14, the present embodiment also provides a fan-out antenna package structure, the fan-out antenna package structure includes: a semiconductor chip 12; a plastic packaging material layer 14, the plastic packaging material layer 14 includes an opposite first surface and a second surface , the plastic packaging material layer 14 is plastic-sealed on the periphery of the semiconductor chip 12, and exposes the front side of the semiconductor chip 12; the metal connection column 13, the metal connection column 13 is located in the plastic packaging material layer 14, and up and down Penetrating through the plastic packaging material layer 14; the antenna structure 16, the antenna structure 16 is located on the first surface of the plastic packaging material layer 14, and is electrically connected to the metal connecting column 13; the rewiring layer 15, the rewiring Layer 15 is located on the second surface of the plastic packaging material lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com