Dual-axis indexing mechanism control system, control method and strapdown inertial group self-calibration method

A technology of indexing mechanism and strapdown inertial group, which is applied in the field of inertial navigation, can solve the problems of complicated equipment maintenance and low calibration accuracy, and achieve the effect of realizing self-calibration function and high-precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

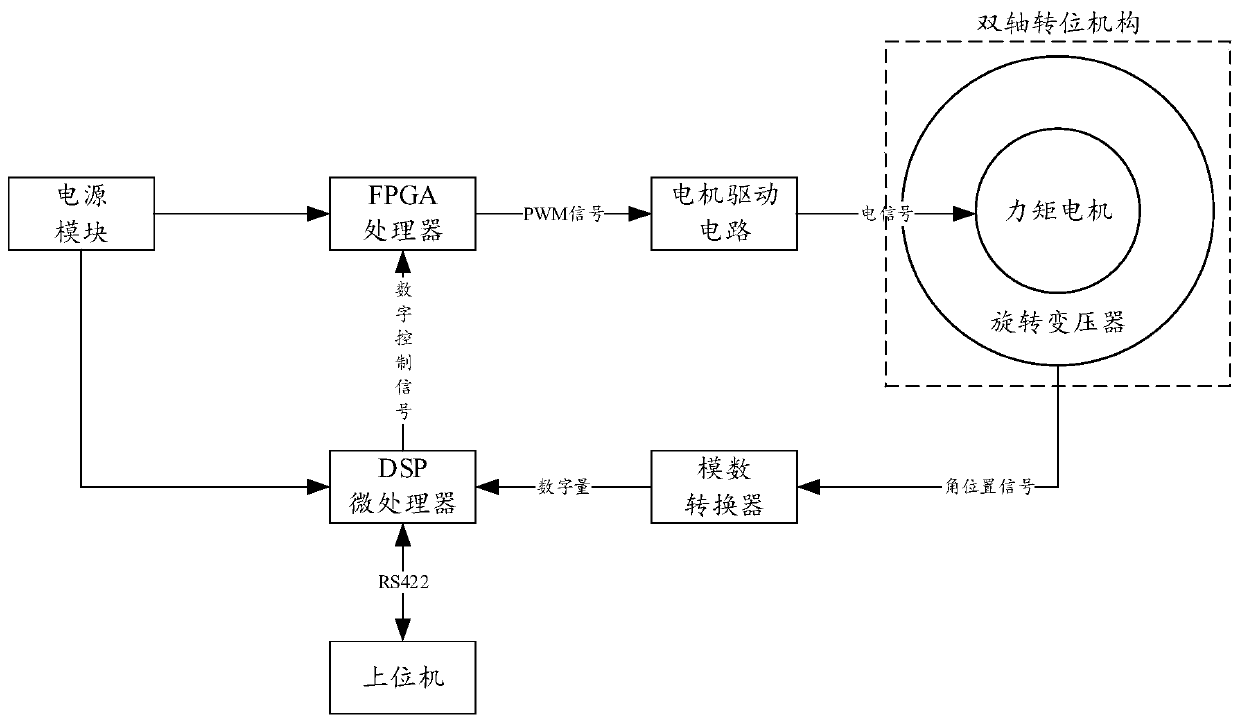

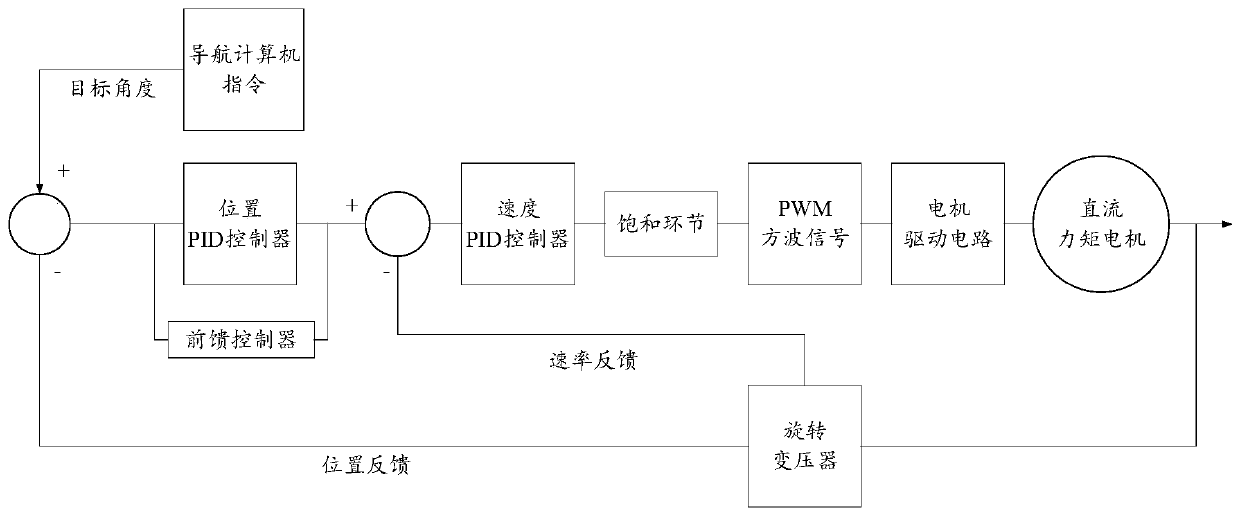

[0036] Such as Figure 1-3 As shown, the present invention discloses a high-precision dual-axis indexing mechanism control system, which includes an angular position sensor, an analog-to-digital converter, a DSP microprocessor, an FPGA processor, a motor drive circuit, and a motor connected in sequence; It should be understood that the strapdown inertial group involved in the present invention is a double-axis indexing strapdown inertial group, and there are two indexing mechanisms inside it for respectively realizing the two axial rotations of the inertial assembly. The online self-calibration function of the inertial group can realize the calibration of the inertial device without removing the strapdown inertial group from the vehicle. The details are as follows.

[0037] The angular position sensor is used to collect the angular position signal of the dual-axis indexing mechanism of the strapdown inertial group, and the angular position signal is an analog quantity; in thi...

Embodiment 2

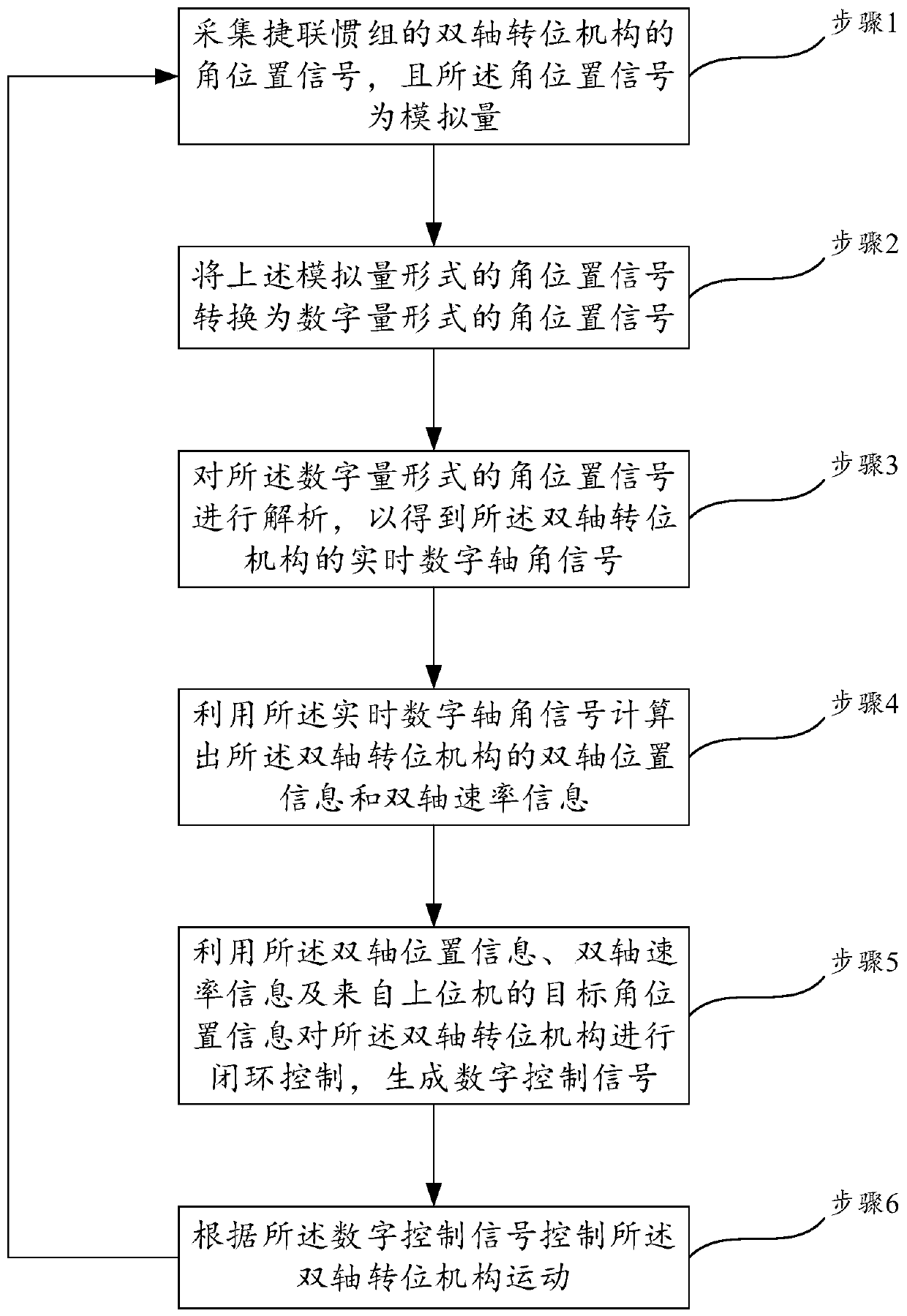

[0046] Based on the same inventive concept as Embodiment 1, this embodiment provides a method for controlling a biaxial indexing mechanism, such as figure 2 , 3 As shown, the control method includes the following steps.

[0047] Step 1, collect the angular position signal of the dual-axis indexing mechanism of the strapdown inertial group, and the angular position signal is an analog quantity. In this embodiment, the angular position of the dual-axis indexing mechanism of the strapdown inertial group is collected by the angular position sensor signal, and the angular position sensor uses a resolver connected to the motor.

[0048] Step 2, performing a high-precision AD conversion step, converting the above-mentioned angular position signal in analog form into an angular position signal in digital form.

[0049]Step 3, analyzing the angular position signal in the form of digital quantity to obtain the real-time digital shaft angle signal of the biaxial indexing mechanism.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com