Preparation method of phyllanthus emblica fermented flavor beverage

A technology for fermenting flavor and embellish fruit, applied in the field of beverage processing, can solve problems such as discomfort, and achieve the effect of strong antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

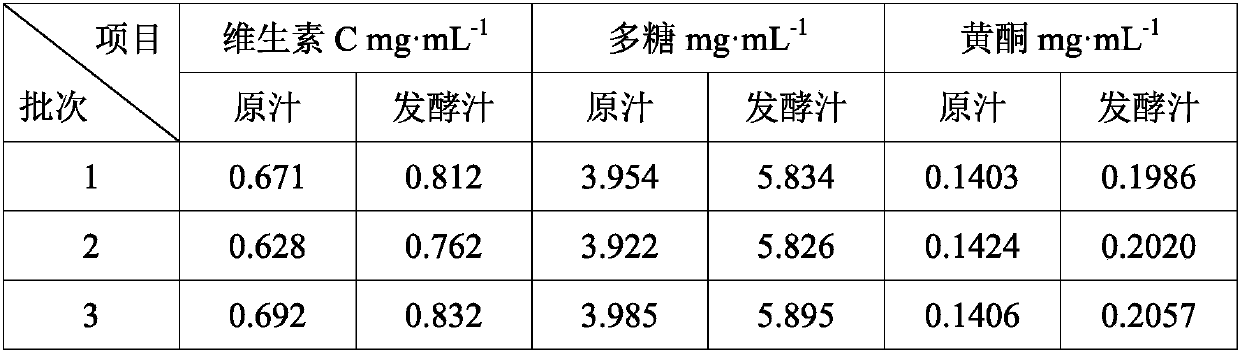

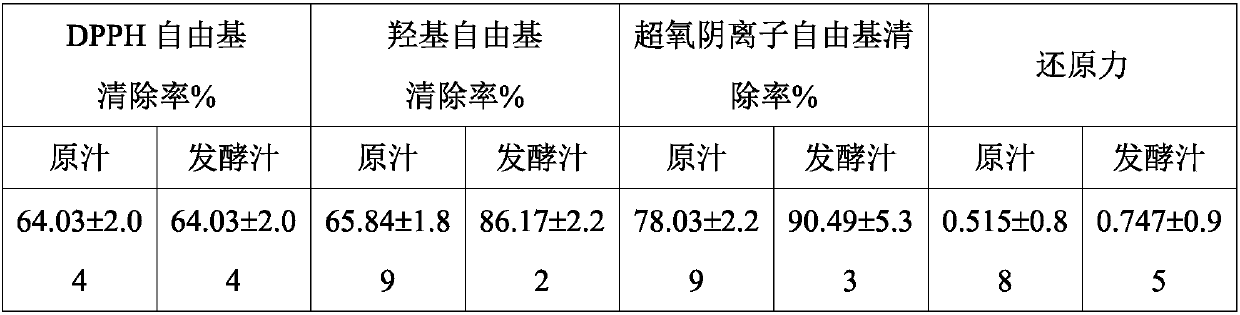

Examples

Embodiment 1

[0021] 1. Selection of raw materials:

[0022] Select freshly picked mature emblica fruits, and pick out impurities such as borers, rotten fruits, branches and leaves.

[0023] 2. Pretreatment of raw materials:

[0024] The screened fruits are rinsed with clean water and soaked for 30 minutes, washed repeatedly 3 times to remove dirt such as surface dust, and then removed and drained.

[0025] 3. Hot fruit:

[0026] Pour the washed emblica into 85°C hot water and scald for 3 minutes, then remove and drain.

[0027] 4. Broken:

[0028] After washing and scalding, the fruit is poured into a crusher and crushed into a particle size of 3-5mm.

[0029] 5. One-step fermentation:

[0030] According to the ratio of fruit mass: Rhizopus.oryzae 0.2%, sucrose 5%, water 20%, strains were dispersed in 35°C water and activated for 15 minutes, mixed with other materials evenly, added to the crushed fruit and stirred fully, so that Various materials were mixed evenly and kept in a loose...

Embodiment 2

[0050] 1. Selection of raw materials:

[0051]Select freshly picked mature emblica fruits, and pick out impurities such as borers, rotten fruits, branches and leaves.

[0052] 2. Pretreatment of raw materials:

[0053] The screened fruits are rinsed with clean water and soaked for 30 minutes, washed repeatedly 3 times to remove dirt such as surface dust, and then removed and drained.

[0054] 3. Hot fruit:

[0055] Pour the washed emblica into 85°C hot water and scald for 3 minutes, then remove and drain.

[0056] 4. Broken:

[0057] After washing and scalding, the fruit is poured into a crusher and crushed into a particle size of 3-5mm.

[0058] 5. One-step fermentation:

[0059] According to the ratio of fruit mass: Rhizopus.oryzae 0.2%, sucrose 5%, water 20%, strains were dispersed in 35°C water and activated for 15 minutes, mixed with other materials evenly, added to the crushed fruit and stirred fully, so that Various materials were mixed evenly and kept in a loose ...

Embodiment 3

[0071] 1. Selection of raw materials:

[0072] Select freshly picked mature emblica fruits, and pick out impurities such as borers, rotten fruits, branches and leaves.

[0073] 2. Pretreatment of raw materials:

[0074] The screened fruits are rinsed with clean water and soaked for 30 minutes, washed repeatedly 3 times to remove dirt such as surface dust, and then removed and drained.

[0075] 3. Hot fruit:

[0076] Pour the washed emblica into 85°C hot water and scald for 3 minutes, then remove and drain.

[0077] 4. Broken:

[0078] After washing and scalding, the fruit is poured into a crusher and crushed into a particle size of 3-5mm.

[0079] 5. One-step fermentation:

[0080] According to the ratio of fruit mass: Rhizopus.oryzae 0.2%, sucrose 5%, water 20%, strains were dispersed in 35°C water and activated for 15 minutes, mixed with other materials evenly, added to the crushed fruit and stirred fully, so that Various materials were mixed evenly and kept in a loose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com