Automatic switching device for working hob and standby hob of shield machine

An automatic switching and shield machine technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of life and health threats to workers, harsh working environment of hobs, and low construction efficiency, and achieve simple structure and improved construction efficiency. Efficiency, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

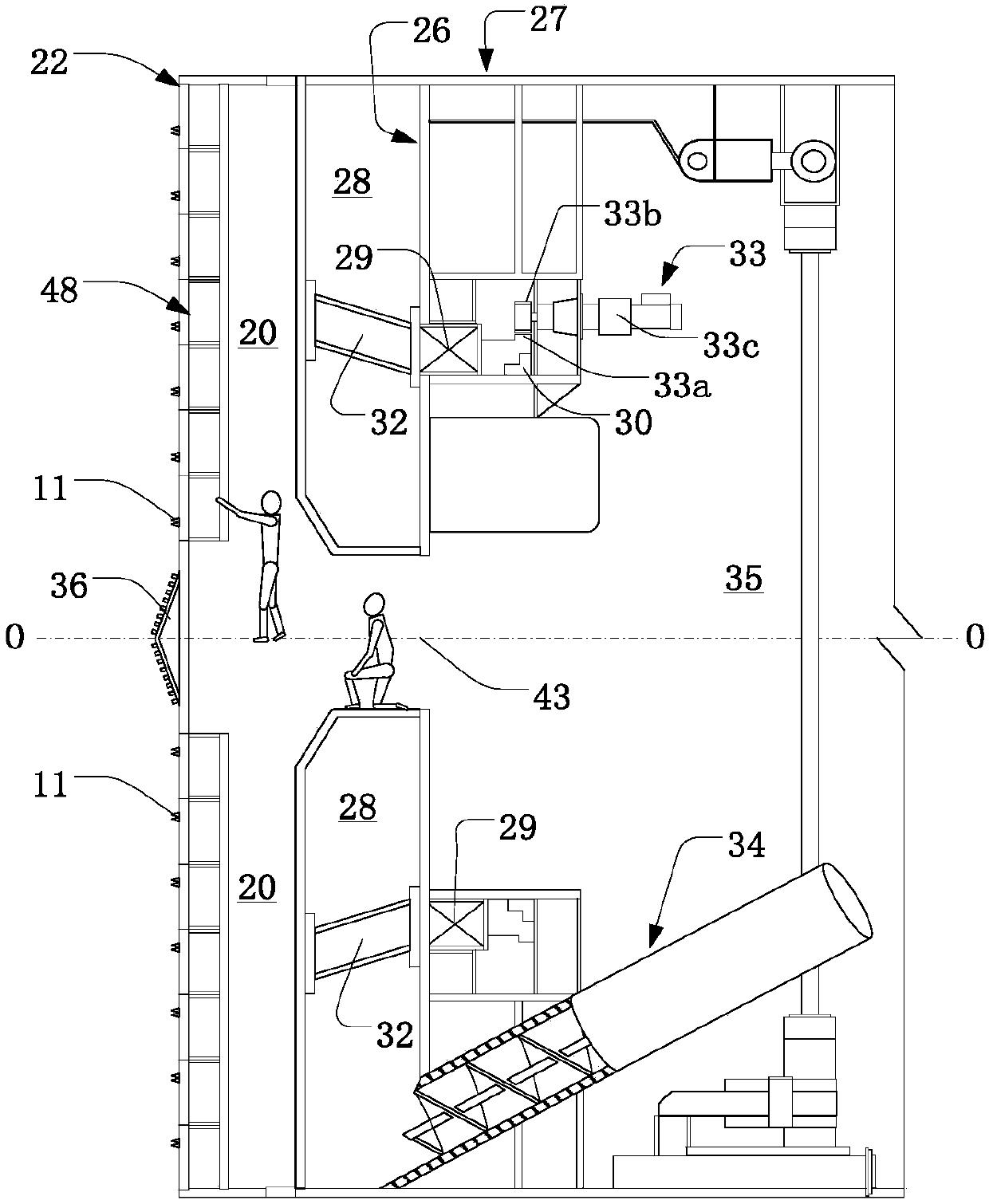

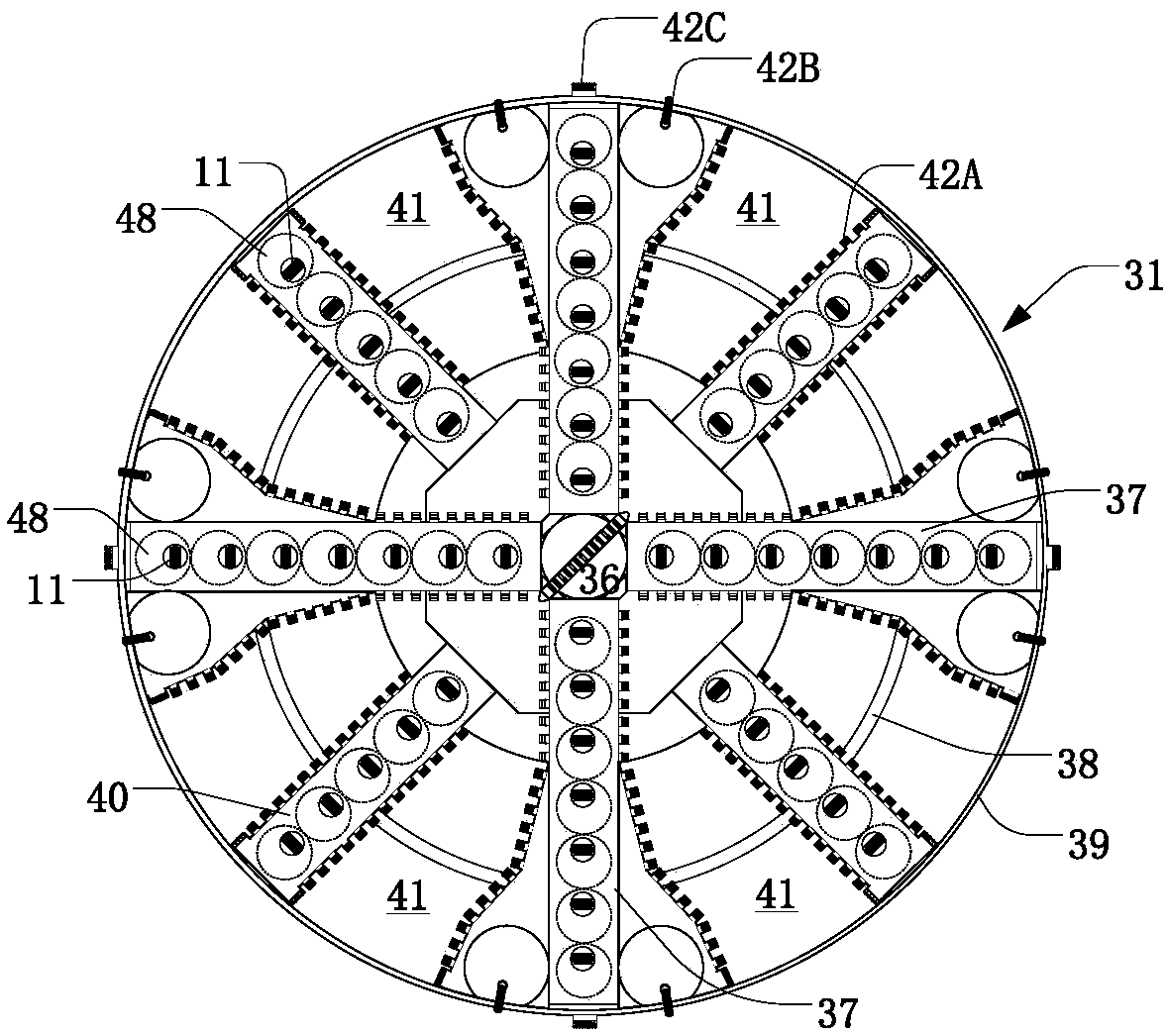

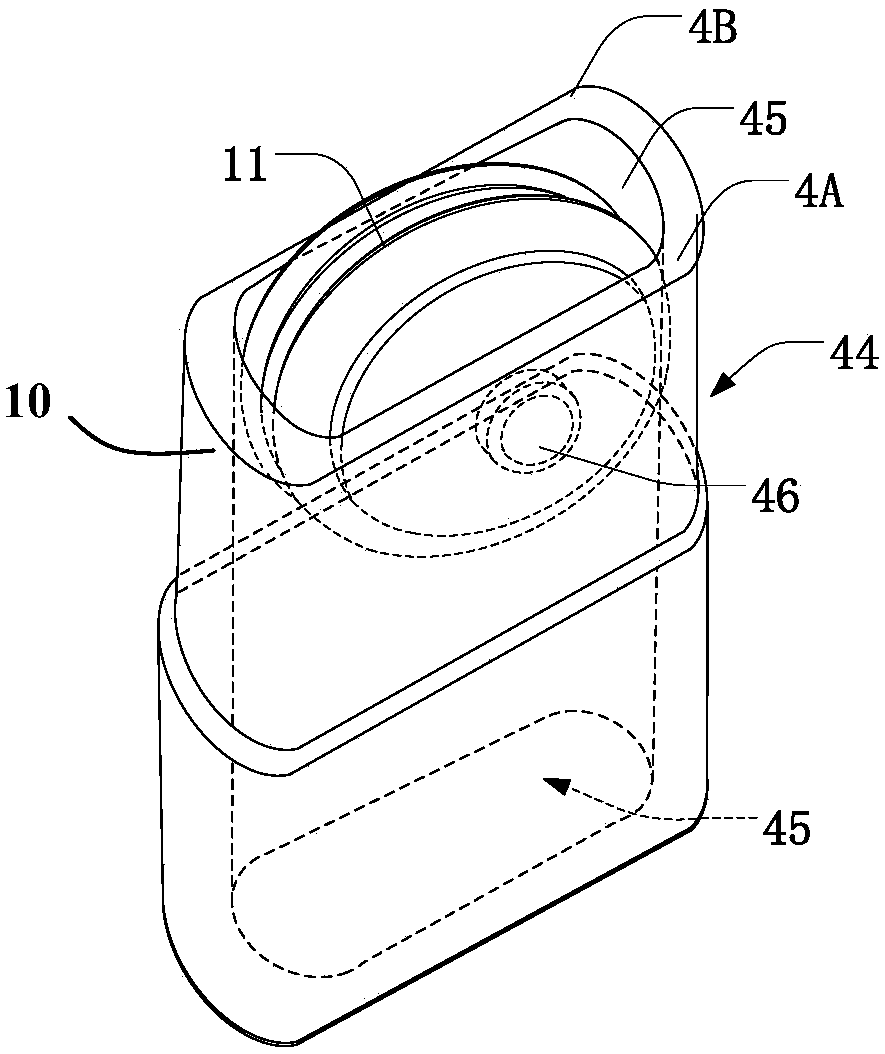

[0023] Such as figure 1 As shown, the shield machine involved in the present invention mainly includes a shield machine body 27, a rotating ring body 29, a cutter head panel 22, a screw conveyor 34, an air cabin 35 and a human cabin 20, which are arranged at the front of the shield machine body 27 There is a pressure separation plate 26, and the front of the pressure separation plate 26 is provided with a soil tank 28 to balance the mud water pressure of the excavation surface. Behind the pressure separation plate 26, the rotating ring body 29 rotates around the shield axis O-O under the support of the rotating bearing 30. The cutter head panel 22 is supported by a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com