Pipe pressure wave velocity test device and method based on pipe flow test loop

A test device, a technology for pipe flow test, applied in the direction of measurement device, fluid velocity measurement, velocity/acceleration/impact measurement, etc., which can solve problems such as large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

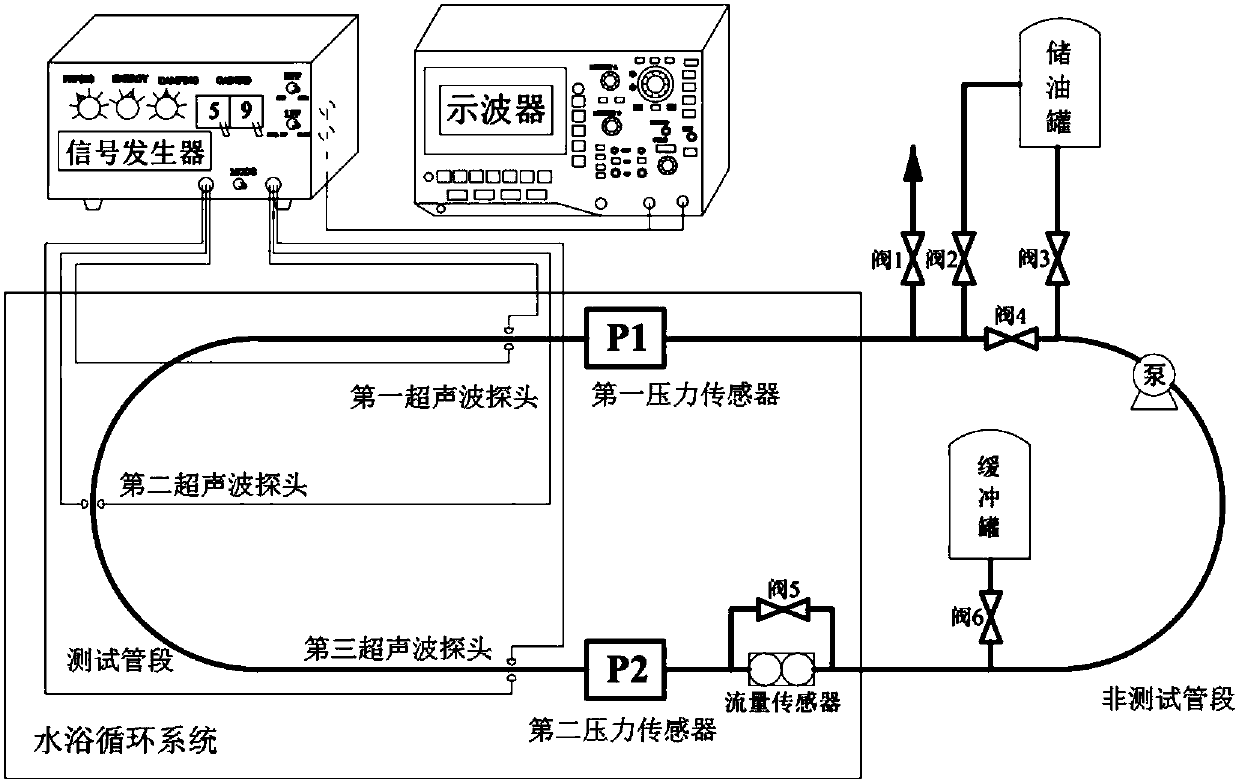

[0059] The purpose of embodiment 1 is to provide a kind of pipeline pressure wave velocity testing device based on the pipeline flow test loop, such as figure 1 As shown, the test device includes a pipe flow loop test device and an ultrasonic velocity test device.

[0060] (1) Pipe flow loop test device

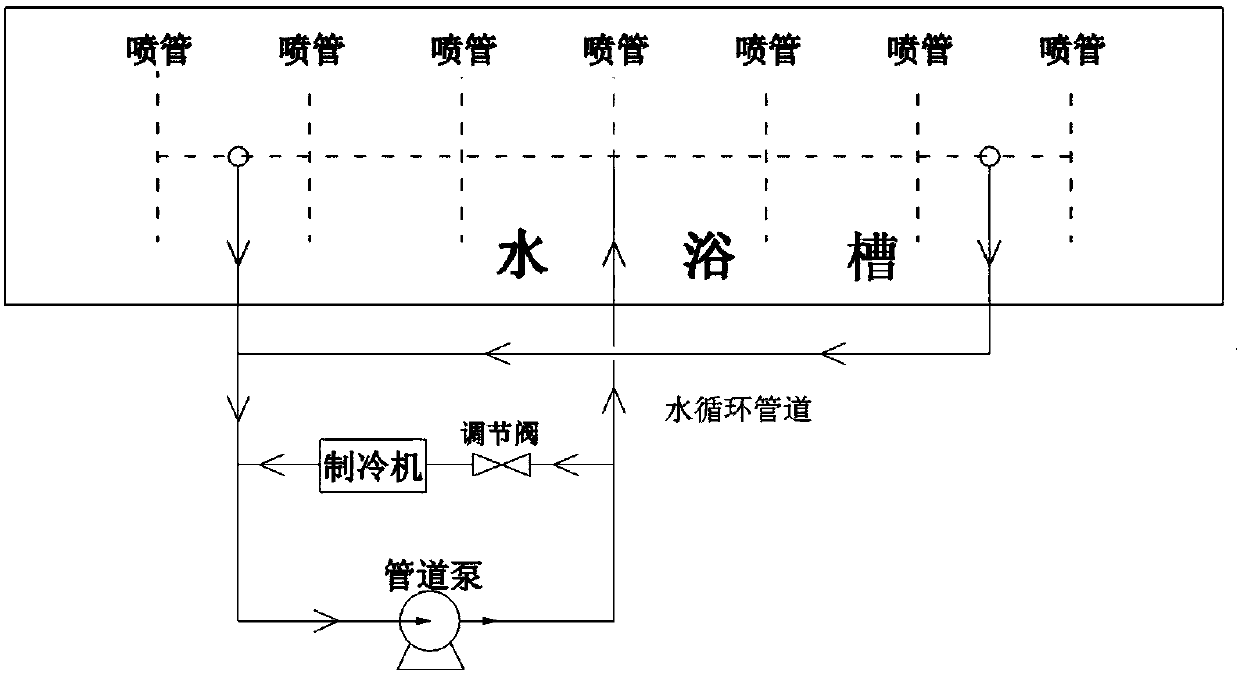

[0061] The pipe flow loop test device includes a test loop system, a water bath circulation system and a data acquisition system. The test loop system, the water bath circulation system and the data acquisition system work together to complete the simulation of different operating conditions of the actual crude oil pipeline.

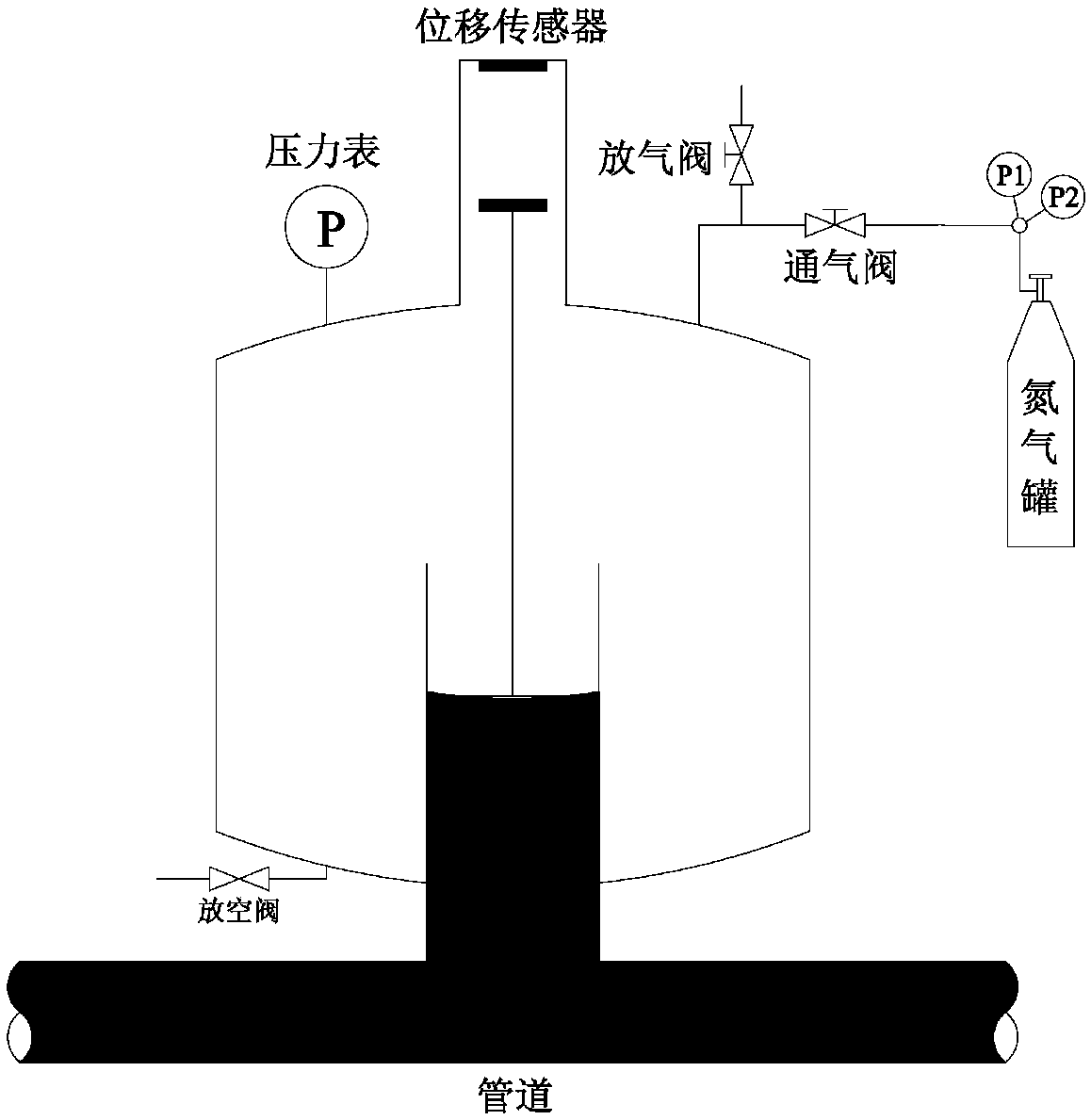

[0062] In this embodiment, the test loop system is used to simulate the flow conditions (temperature, pressure, shear conditions) of crude oil in the actual pipeline, including test loops, oil storage tanks, pumps, buffer tanks and several valves . Specifically, the pipe material of the test loop is 304 stainless steel pipe, its elastic modulus E is ...

Embodiment 2

[0077] The second object of the present invention is to provide a kind of pressure wave velocity test method based on pipe flow test loop, such as Figure 4 shown.

[0078] In order to achieve the above object, the present invention adopts the following technical scheme: the method is based on the pressure wave velocity testing device in the indoor pipe flow test loop, and the determination of the pressure wave velocity at different positions along the actual pipeline is realized through the following operation steps:

[0079] Step (1): Measure the viscosity of the oil at different temperatures, obtain the viscosity-temperature curve of the oil viscosity changing with temperature, and determine the abnormal point of the oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com