Preparation process of cut carnation flower preservation reagent for onion extracting solution

A production process, carnation technology, applied in the production process field of carnation cut flower preservation reagent, can solve the problems of chemical preservation liquid pollution, harmful substances, containing human body, etc., achieve growth inhibition, electrical conductivity rises smoothly, and increase osmotic potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

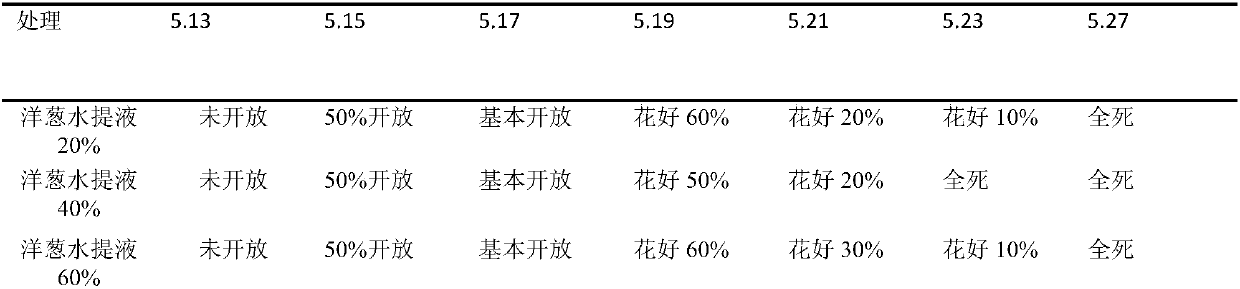

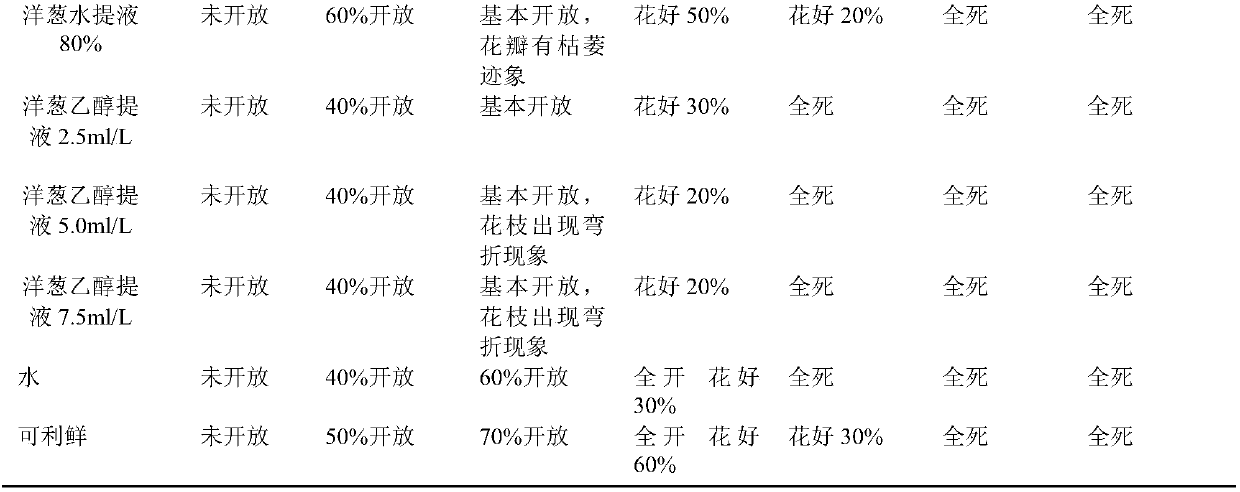

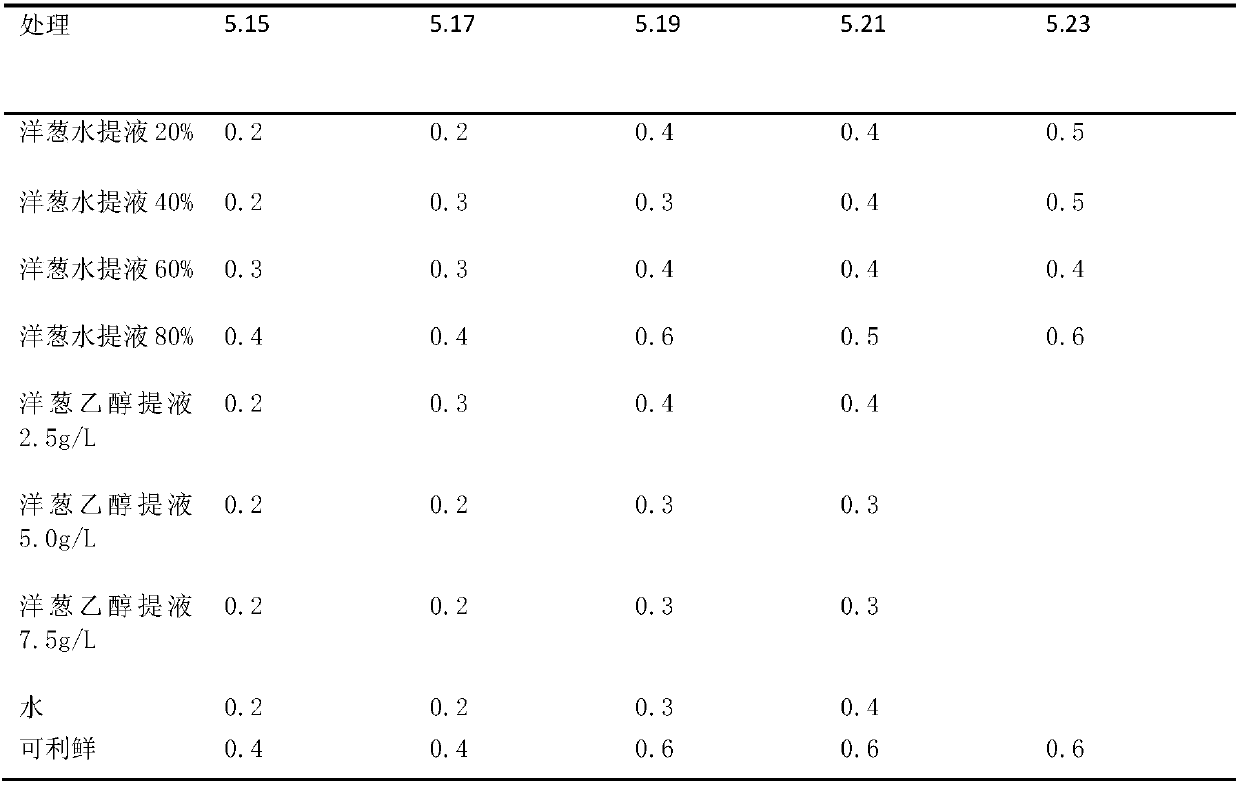

[0017] The invention provides a recipe for the preparation of carnation cut flower fresh-keeping reagent of onion extract, and the test method is as follows:

[0018] Step 1: Pretreatment of onions, air-dry the onions in a cool place, and then put them into a drying oven for drying at a temperature of 35-40°C for 12 hours. Use a pulverizer to crush the dried onions, pass through a 20-mesh sieve, bag them separately, and store them at 4°C for later use;

[0019] Step 2: Preparation of the onion water extract, weigh 40g of the crushed onion sample, divide it into 2 parts for later use (20g each), put each part into a measuring cup, add 1000ml of water, and soak in a warm water bath at 50°C for 12 hours Boil for another 30 minutes, filter to remove slag, and constant volume in a 1000ml volumetric flask to obtain the stock solution of plant extract, cool at 4°C and store for later use, with a concentration of 0.02g / L;

[0020] Step 3: Carnation pretreatment, take carnation cut fl...

Embodiment 2

[0024] The present invention provides a preparation method of carnation cut flower fresh-keeping reagent of onion extract, and the configuration method is as follows:

[0025] Step 1: Pretreatment of onions, air-dry the onions in a cool place, and then put them into a drying oven for drying at a temperature of 35-40°C for 12 hours. Use a pulverizer to crush the dried onions, pass through a 20-mesh sieve, bag them separately, and store them at 4°C for later use;

[0026] Step 2: Preparation of onion ethanol extract, weigh 50g of crushed onion sample, add quantitative 95% ethanol, the standard is to immerse the sample by more than 4cm according to the sample volume, soak, put it in a shaker and shake for 48h. Filtrate to obtain the filtrate and residue. The second time: add an appropriate amount of 95% ethanol to the residue that was lifted for the first time, just immerse the sample by 1 cm, soak it, and shake it in a shaker for 24 hours. Filtrate to obtain the filtrate and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com