Method for preparing olive leaf medicated liquid

A technology of olive leaves and olives, which is applied in the direction of medical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of ignoring the huge value of olive leaves, so as to improve health care, reduce oxidation, The effect of process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

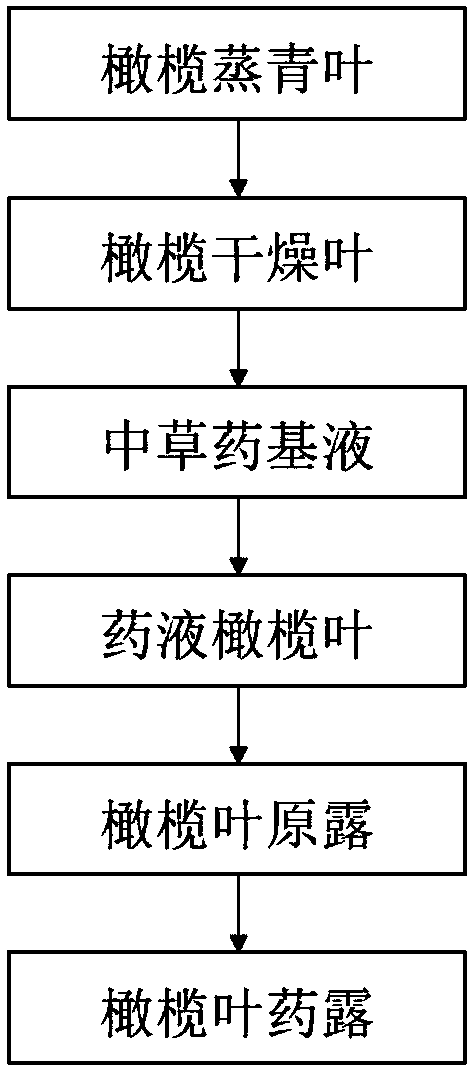

[0023] Such as figure 1 Shown, the invention provides a kind of preparation method of olive leaf medicine dew, comprises the steps:

[0024] Step 1. Preparation of olive steamed green leaves: spread out the picked olive leaves and place them for 2-3 hours, then put them in a de-enzyming machine for de-enzyming treatment. In the first stage, put in 20-25 kg / h of leaves In the greening machine, the steaming humidity is 50-55%, the steaming temperature is 140-150°C, and the steaming time is 8-12s. ℃; in the second stage, the amount of leaves to be thrown is 5~10 kg / h into the greening machine, the humidity of greening is 45~50%, the temperature of greening is 60~70℃, and the time of greening is 20~30s. Pour it out and spread it out, and use a cooling device to cool it to 15-25° C. for 180-200 s to obtain steamed green leaves of olives. The water content of the steamed green leaves of olives is 50-55%.

[0025] Step 2. Preparation of dried olive leaves: place the steamed green l...

Embodiment 1

[0031] Spread out the picked olive leaves for 2 hours, and then put them in the de-enzyming machine for de-enzyming treatment. In the first stage, put them into the de-enzyming machine with the amount of leaves thrown at 20kg / h. The steaming humidity is 50%, and the steaming temperature is 50%. at 140°C, and the steaming time is 8s. After the steaming is finished, quickly pour it out and spread it out, and let it cool down to 45°C; in the second stage, put the leaves into the greening machine at a rate of 5 kg / h, and the greening humidity is 45%, the finishing temperature is 60°C, and the finishing time is 20s. After finishing, quickly pour it out and spread it out, and use a cooling device to cool it to 15°C. The cooling time is 180s, and the steamed green leaves of olives are obtained. The water content of the steamed green leaves is 50%; the steamed green leaves of the olives are placed in a dryer for a drying treatment, the drying pressure is set to 2kPa, the drying tempera...

Embodiment 2

[0033] Spread the plucked olive leaves for 3 hours, and then put them in the greening machine for greening treatment. In the first stage, put them into the greening machine with the amount of leaves thrown at 25 kg / h. The steaming humidity is 55%. The temperature is 150°C, and the steaming time is 12s. After the steaming is completed, it is quickly poured out and spread out to cool it down to 55°C. In the second stage, put the leaves into the greening machine at a rate of 10 kg / h, and the greening humidity 50%, the finishing temperature is 70°C, and the finishing time is 30s. After finishing, pour it out and spread it out quickly, and use a cooling device to cool it to 25°C. The cooling time is 200s, and the steamed green leaves of olives are obtained. The water content of the steamed green leaves of olives is 55%; the steamed green leaves of olives are placed in a dryer for a drying treatment, the drying pressure is set to 2.5kPa, the drying temperature is 150°C, and the dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com