Automatic coating device

A coating device and coating technology are applied to the device and coating for coating liquid on the surface, which can solve the problems of high viscosity of composite materials for environmental protection desulfurization, unsatisfactory coating film, and uneven coating. , to achieve the effect of easy promotion and use, saving man-hours and labor costs, and high coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

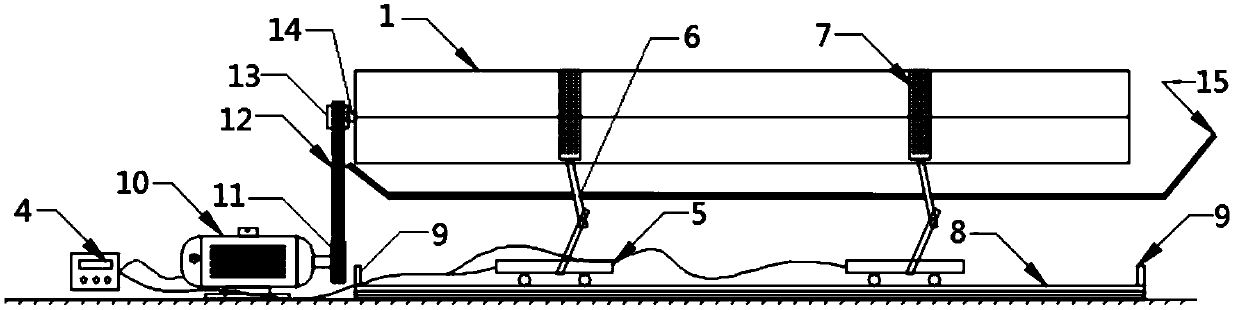

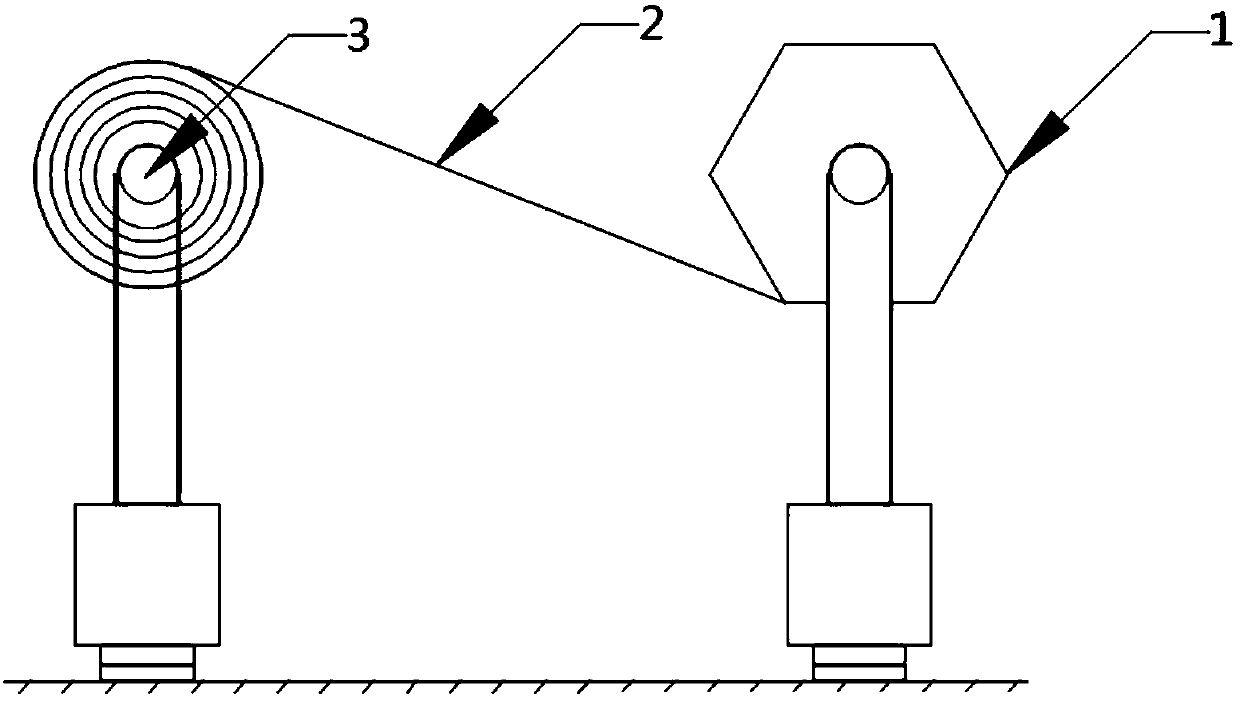

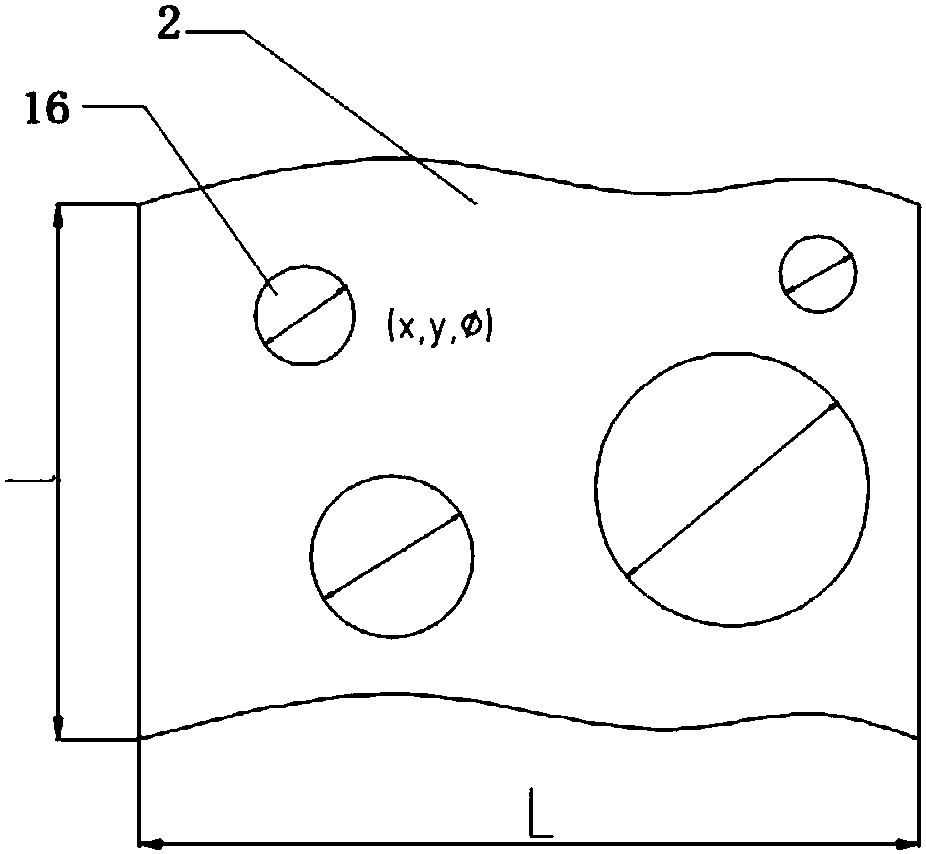

[0022] Example: refer to figure 1 and 2 As shown, an automatic coating device includes a horizontally arranged coating column core 1, a driving mechanism for driving the coating column core 1 to rotate, is connected with the coating column core 1 through a film 2, and follows the coating column The core 1 rotates the film feeder 3, and the controller 4 electrically connected to the drive mechanism; two groups of intelligent coating machines are arranged on the front side of the coating column core 1, and each group of intelligent coating machines includes a 4. A stroke trolley 5 electrically connected and reciprocating along the length direction of the coating column core 1, and a mechanical arm 6 arranged on the stroke trolley 5; a coating brush 7 with a spray gun built in is provided on the mechanical arm 6, The spraying gun sprays the composite material for desulfurization on the film 2 wrapped on the outer surface of the coated column core 1, and the coating brush 7 moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com