Electrically controlled brake power-assisted system and vehicle brake system

A technology of electric control and electronic control unit, which is applied in the direction of brake transmission, brake, vehicle parts, etc., can solve the problems of high technical requirements, unrealization, and high cost of screw screws, and achieve compact structure, uniform wear, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of an electronically controlled brake booster system and a vehicle brake system involved in the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

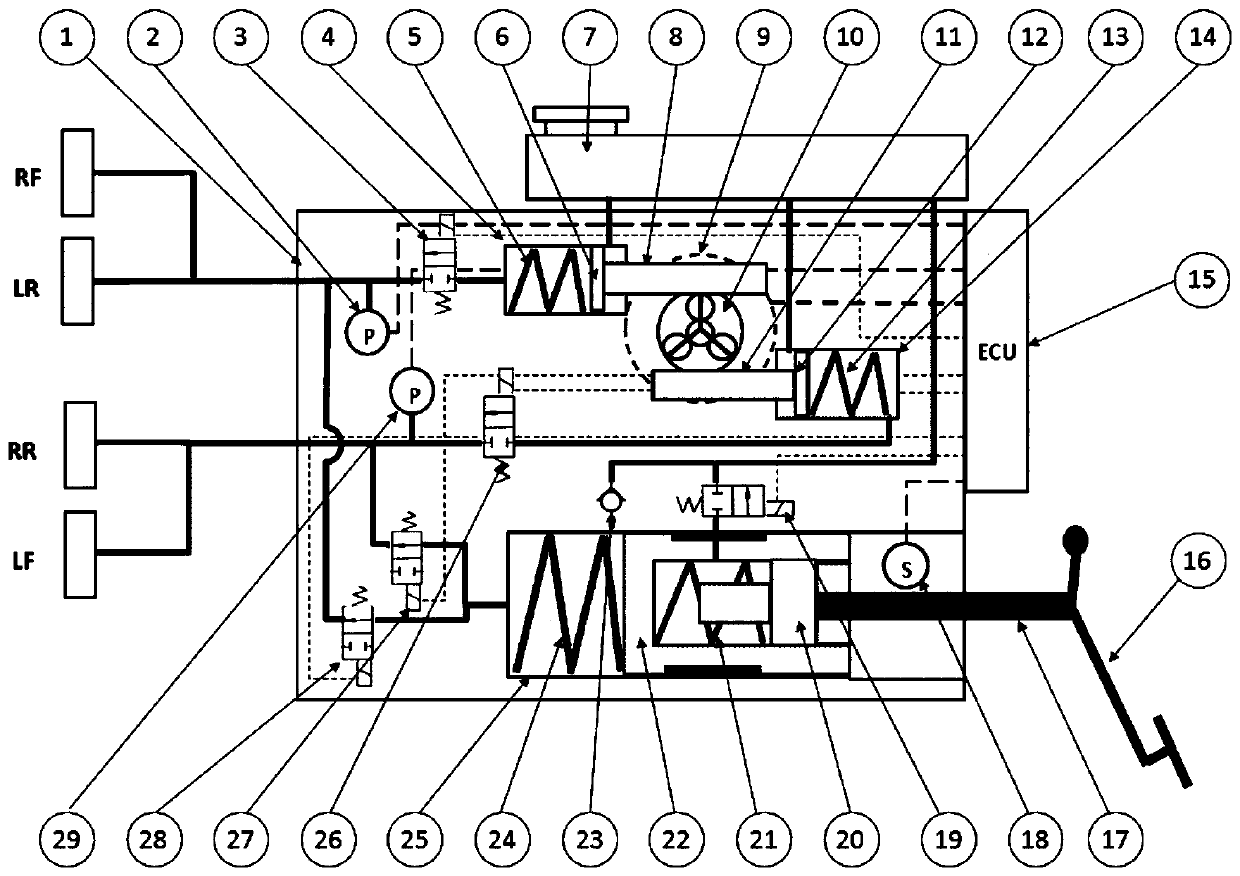

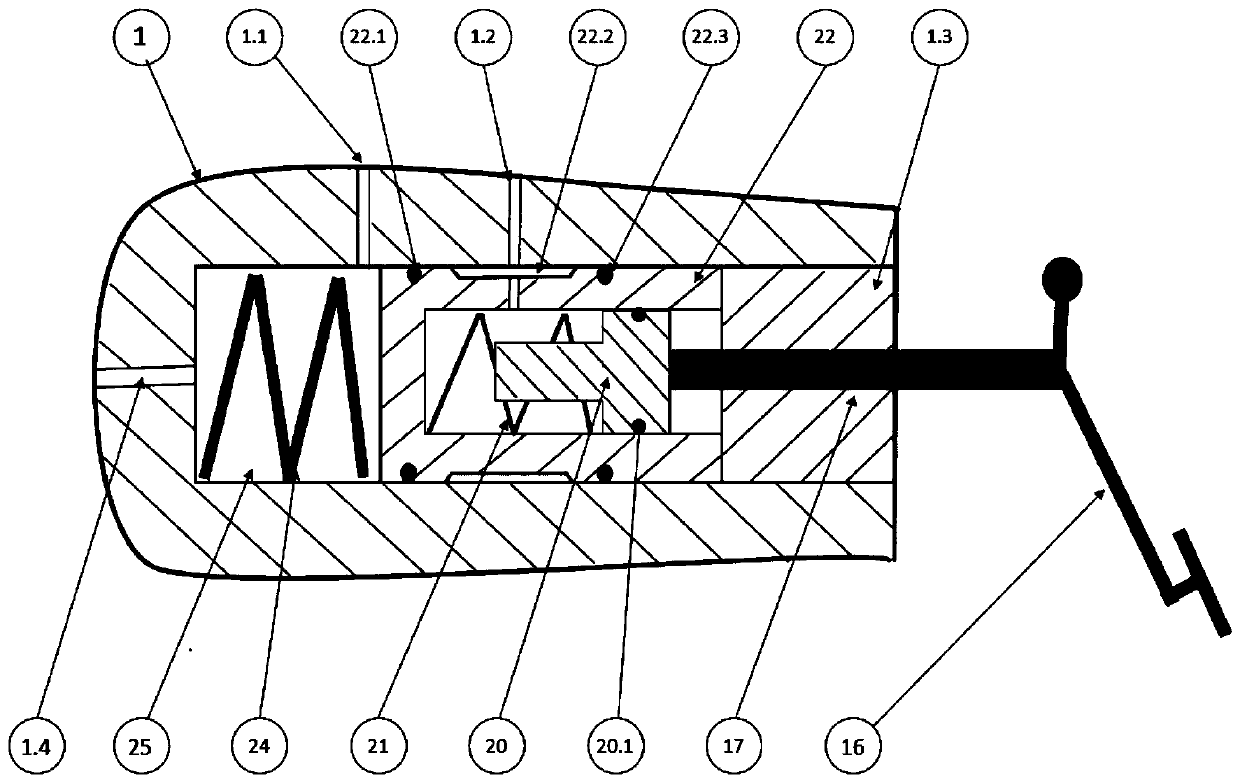

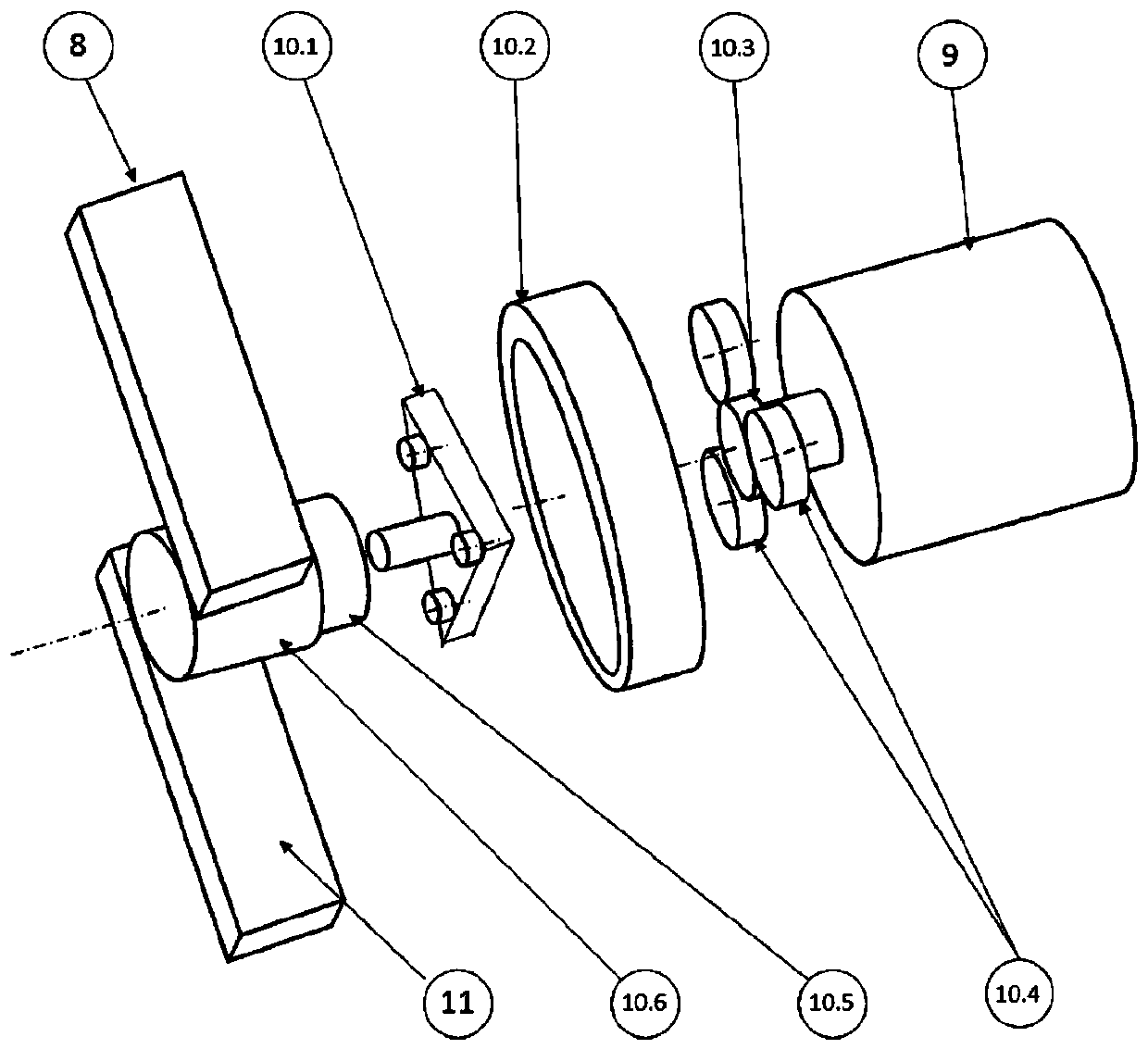

[0045] see figure 1 As shown, a vehicle brake system provided according to an embodiment of the present invention includes an electronically controlled brake booster system 1, a right front left rear power brake cylinder pipeline pressure sensor 2, a right front left rear power brake cylinder tube Road normally closed solenoid valve 3, right front left rear booster brake cylinder 4, right front left rear booster brake cylinder return spring 5, right front left rear booster brake cylinder piston 6, brake fluid pot 7, right front left rear booster brake Cylinder push rod (rack) 8, drive motor 9, planetary gear reduction mechanism 10, left front and right rear power-assisted brake cylinder push rod (rack) 11, left front and right re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com