Preparation method of mechanical foamed asphalt warm-mixing recycled mixture

A technology of recycled mixture and mechanical foaming, which is used in ceramic products, applications, household appliances, etc., can solve the problems of white materials, save energy, improve the effect of wrapping, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

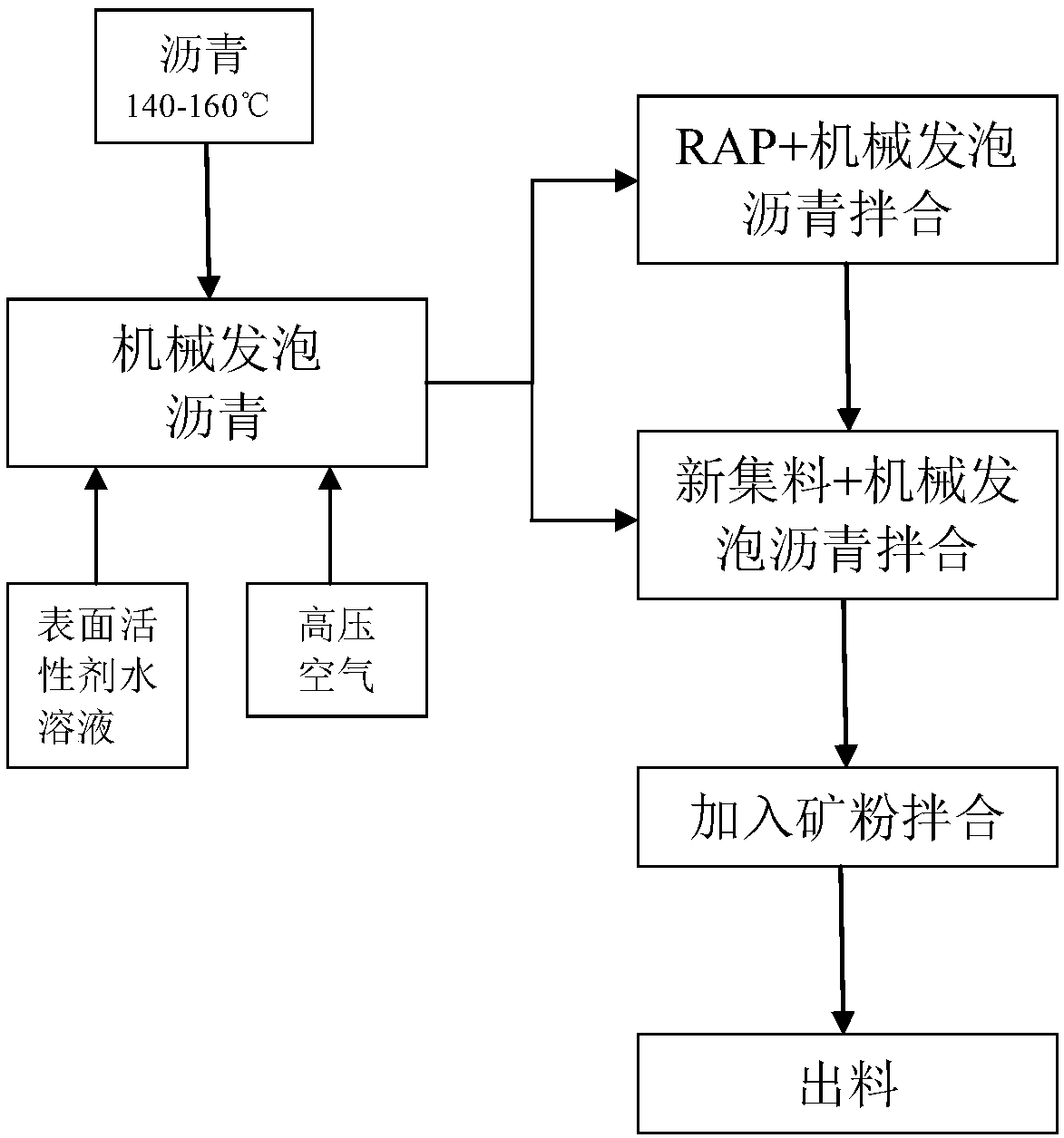

[0027] The indoor preparation method of mechanically foamed asphalt warm mix recycled mixture is as follows:

[0028] (1) Preparation of mechanically foamed asphalt: heat the asphalt to 160°C to make the asphalt have sufficient fluidity, add the asphalt into the foaming chamber heated to 160°C, and spray 2.5% non-ionic surfactant aqueous solution of the asphalt mass at the same time And the air with a pressure of 100bar makes the hot asphalt fully contact and foam in the foaming cavity; the nonionic surfactant aqueous solution is nonylphenol polyoxyethylene ether and polyglycerol succinate aqueous solution.

[0029] (2) Heat 40 parts of the old material RAP that has been crushed and screened into two grades to 90°C and put it into the mixing tank, add 1.2 parts of mechanically foamed asphalt prepared by step (1) and mix for 90 seconds;

[0030] (3) Add 55 parts of new aggregate heated to 170°C to the mixed product of step (2), and at the same time add 1.8 parts of mechanically...

Embodiment 2

[0033] The indoor preparation method of mechanically foamed asphalt warm mix recycled mixture is as follows:

[0034] (1) Preparation of mechanically foamed asphalt: heat the asphalt to 140°C to make the asphalt have sufficient fluidity, add the asphalt into the foaming chamber heated to 150°C, and spray 2.5% nonionic surfactant aqueous solution of the asphalt mass at the same time And the air with a pressure of 100bar makes the hot asphalt fully contact and foam in the foaming cavity; the nonionic surfactant aqueous solution is a dodecylphenol polyoxyethylene ether aqueous solution.

[0035] (2) Heat 30 parts of the old material RAP that has been crushed and screened into two grades to 80°C and put it into the mixing tank, add 1.0 parts of mechanically foamed asphalt prepared by step (1) and mix for 60 seconds;

[0036] (3) Add 64 parts of new aggregate heated to 160°C to the mixed product of step (2), and at the same time add 2.6 parts of mechanically foamed asphalt prepared...

Embodiment 3

[0039] The indoor preparation method of mechanically foamed asphalt warm mix recycled mixture is as follows:

[0040] (1) Preparation of mechanically foamed asphalt: heat the asphalt to 155°C to make the asphalt have sufficient fluidity, add the asphalt into the foaming chamber heated to 155°C, and spray 2.5% non-ionic surfactant aqueous solution of the asphalt mass at the same time And the air with a pressure of 100bar makes the hot asphalt fully contact and foam in the foaming cavity; the non-ionic surfactant aqueous solution is an aqueous solution of octylphenol polyoxyethylene ether and polyglycerol lactate.

[0041] (2) Heat 50 parts of the old material RAP that has been crushed and screened into two grades to 90°C and put it into the mixing tank, add 1.1 parts of mechanically foamed asphalt prepared by step (1) and mix for 90 seconds;

[0042] (3) Add 44 parts of new aggregate heated to 180°C to the mixed product of step (2), and at the same time add 1.4 parts of mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com