Mixture for disposable medical infusion product and preparation method of mixture

A compound and disposable technology, applied in the field of medical materials, can solve problems such as easy cracking and insufficient elasticity, achieve good biocompatibility, ensure treatment safety, improve elasticity and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

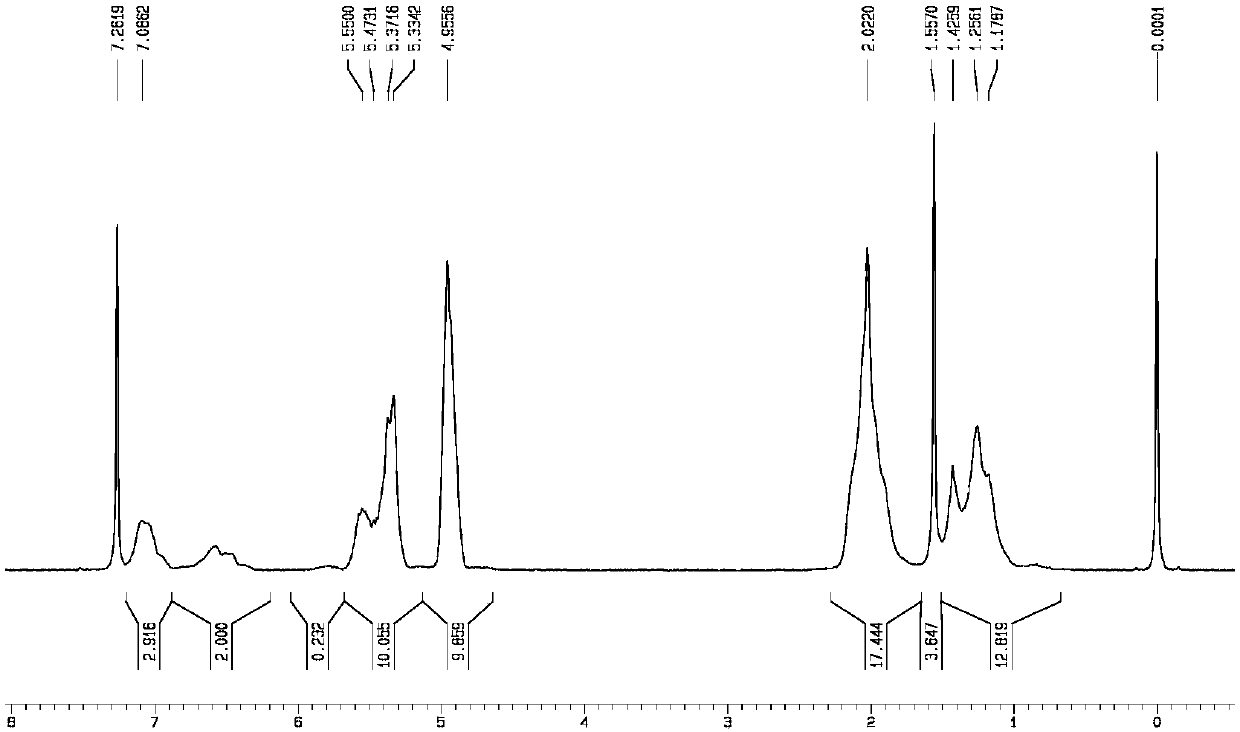

Image

Examples

Embodiment 1

[0059] Step (a): Add 2.5 liters of cyclohexane and raffinate mixture into a 5 liter polymerization kettle purged with nitrogen. The temperature of the mixture was raised to 50° C., 10 g of styrene and 0.25 g of regulator tetrahydrofurfuryl alcohol ethyl ether were added first, and then 3.57 mmol of n-butyllithium was added to initiate the reaction.

[0060] Step (b): After stirring and reacting for 20 to 60 minutes, add a mixture of 20 g of isoprene and 160 g of butadiene to the active polymer, during which the reaction temperature is controlled at 40 to 60 ° C, and the reaction is stirred for 20 to 60 minutes;

[0061] Step (c): Then add 10 g of styrene to the active polymer, and stir for 20 to 60 minutes to react.

[0062] Step (d): The polymer after the polymerization in step (c) is pressed into a 5-liter hydrogenation tank, 3.0 mmol of n-butyllithium is added, the stirring reaction is terminated by passing hydrogen gas for 5-25 minutes, and 68 mmg of benzoic acid is added ...

Embodiment 2

[0064] According to the method of Example 1, but changing the contents of styrene, isoprene, butadiene, butyllithium and regulators, TPEs numbered 2, 3, 4, 5, and 6 in Table 1 were prepared.

[0065] Table 1 Structure of TPE

[0066] Numbering

Embodiment 3

[0068] On the co-rotating twin-screw extruder, the TPE numbered 1-6 is cut into particles, wherein the temperature of the extrusion feeding section is 180°C; the conveying section is 200°C; the homogenizing metering section is 220°C; the head temperature is 210°C; The screw speed is 200rpm; then, the formula is 100 parts of TPE particles prepared by each number, respectively, 30 parts of PP and 0.4 parts of antioxidant (specific materials such as 1010) are melted and mixed in a co-rotating twin-screw extruder, and made pellets to obtain the non-PVC material of the present invention. Wherein the extrusion feeding section temperature is 190°C; the conveying section is 210°C; the homogenizing metering section is 220°C; the head temperature is 210°C; the screw speed is 240rpm. In this embodiment, the structures of the TPEs are shown in Table 1 respectively.

[0069] Through Example 3, TPE, PP, and antioxidants of each number in Examples 1 and 2 were mixed to prepare corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com