Pipe gallery guide wall external formwork and building method thereof

An external formwork and guide wall technology, applied in the direction of formwork/formwork/work frame, connection of formwork/formwork/work frame, and on-site preparation of building components, which can solve multiple labor costs, support components, and ease of use. Problems such as wrong platform, honeycomb, pockmarked surface, and low turnover times occur, so as to reduce the time of mold installation and mold removal, reduce the places prone to pulp leakage, and alleviate the phenomenon of mold expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

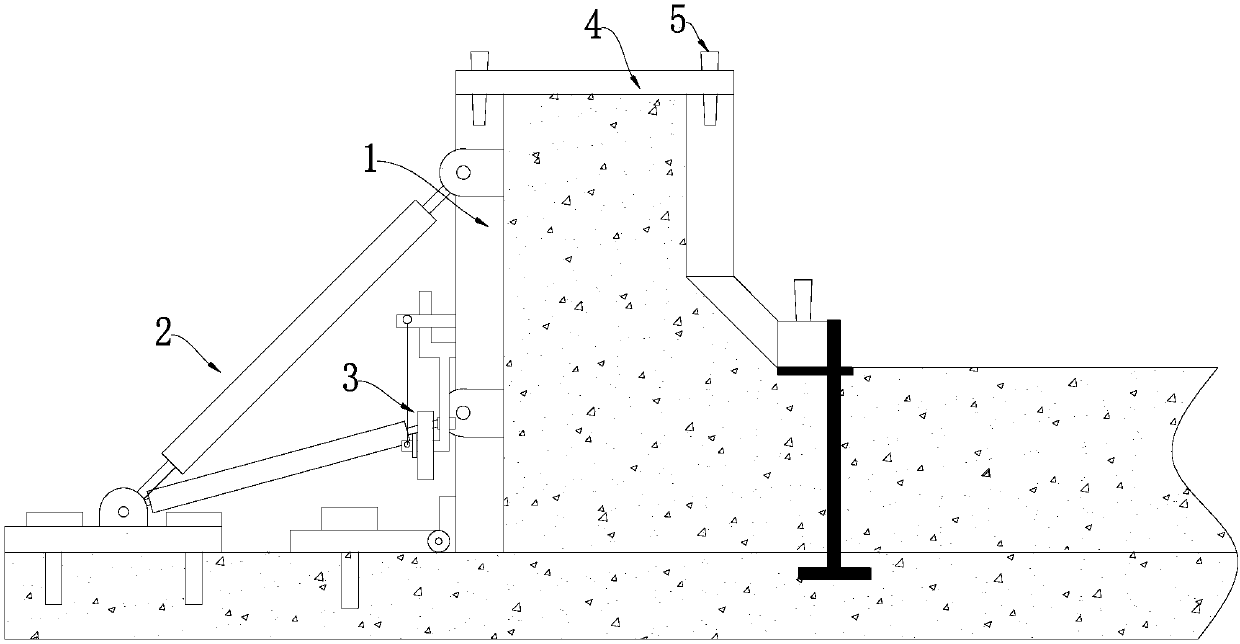

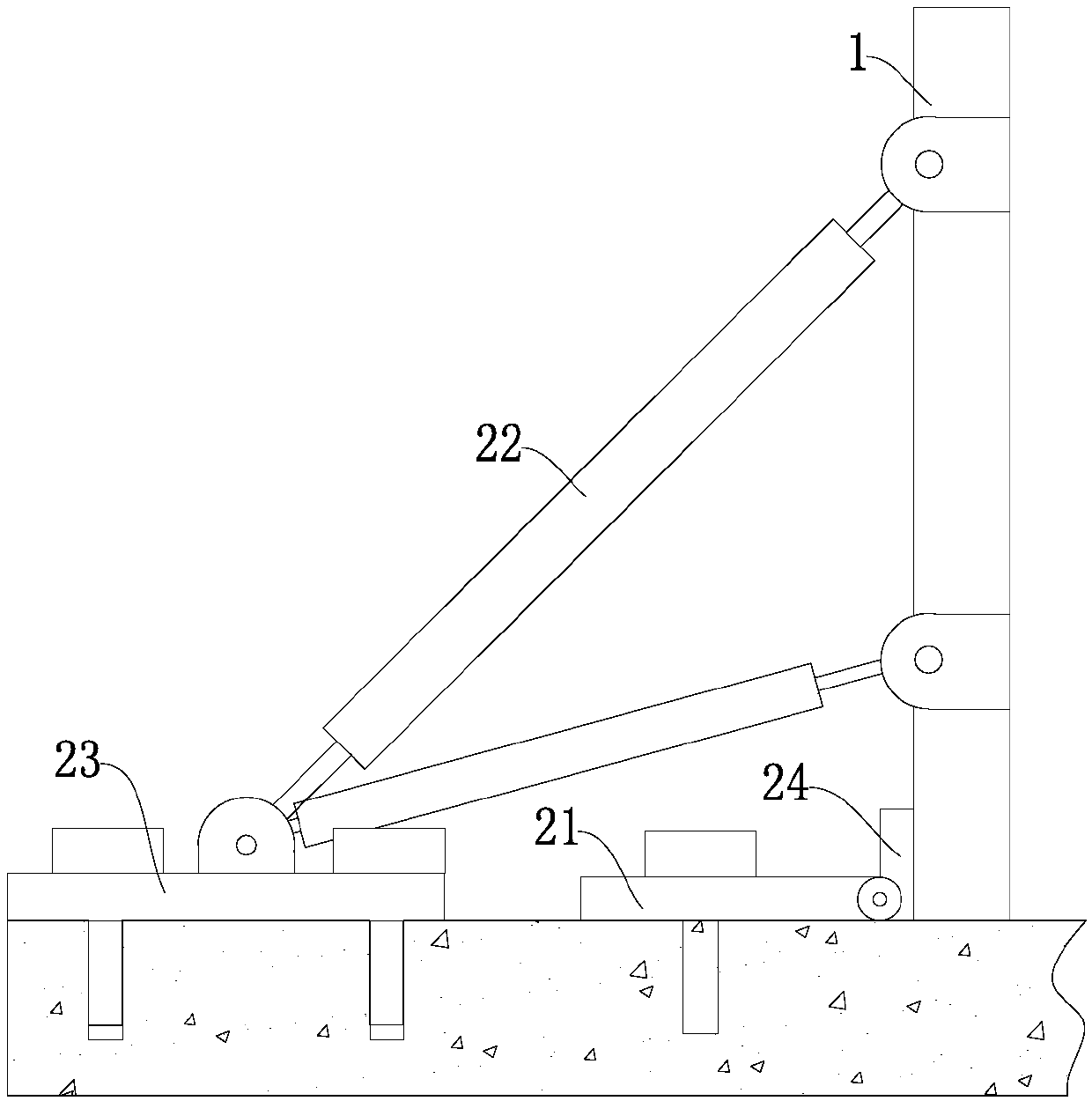

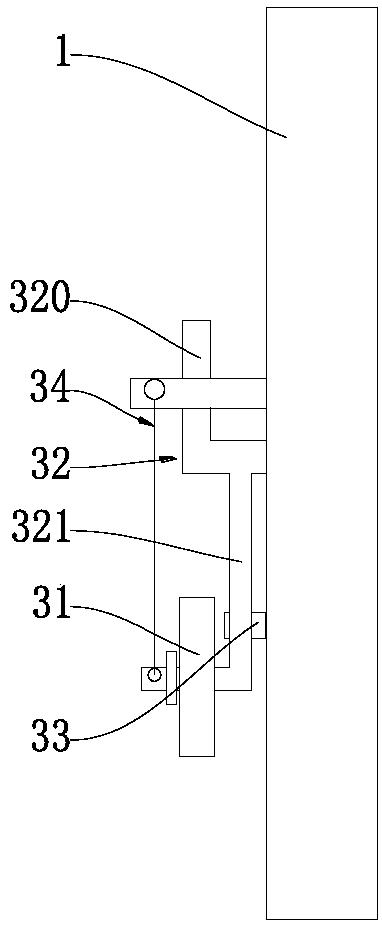

[0036] Formwork outside the pipe gallery guide wall, such as figure 1 As shown, it includes a plurality of steel outer formwork units 1 distributed longitudinally along the pipe gallery and a connecting piece that connects two adjacent outer formwork units 1 together; the connecting piece is detachably connected with the outer formwork unit 1; A supporting system 2 for supporting the outer formwork unit 1 is provided on the outer side of the block outer formwork unit 1 ; a walking system 3 is provided at the bottom of each outer formwork unit 1 .

[0037] In the present invention, the outer formwork unit 1 is a steel formwork, which can be made of a larger area of steel plates, that is, compared with the prior art, the unit plates constituting the outer formwork of the pipe gallery guide wall are reduced, and the adjacent units are correspondingly red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com