A floor beam installation bracket and its construction method

A technology for installing brackets and floor beams, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of long occupancy of tower cranes, difficulty in adjusting floor beams, etc., achieve high construction efficiency, improve construction quality, The effect of reducing the time taken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

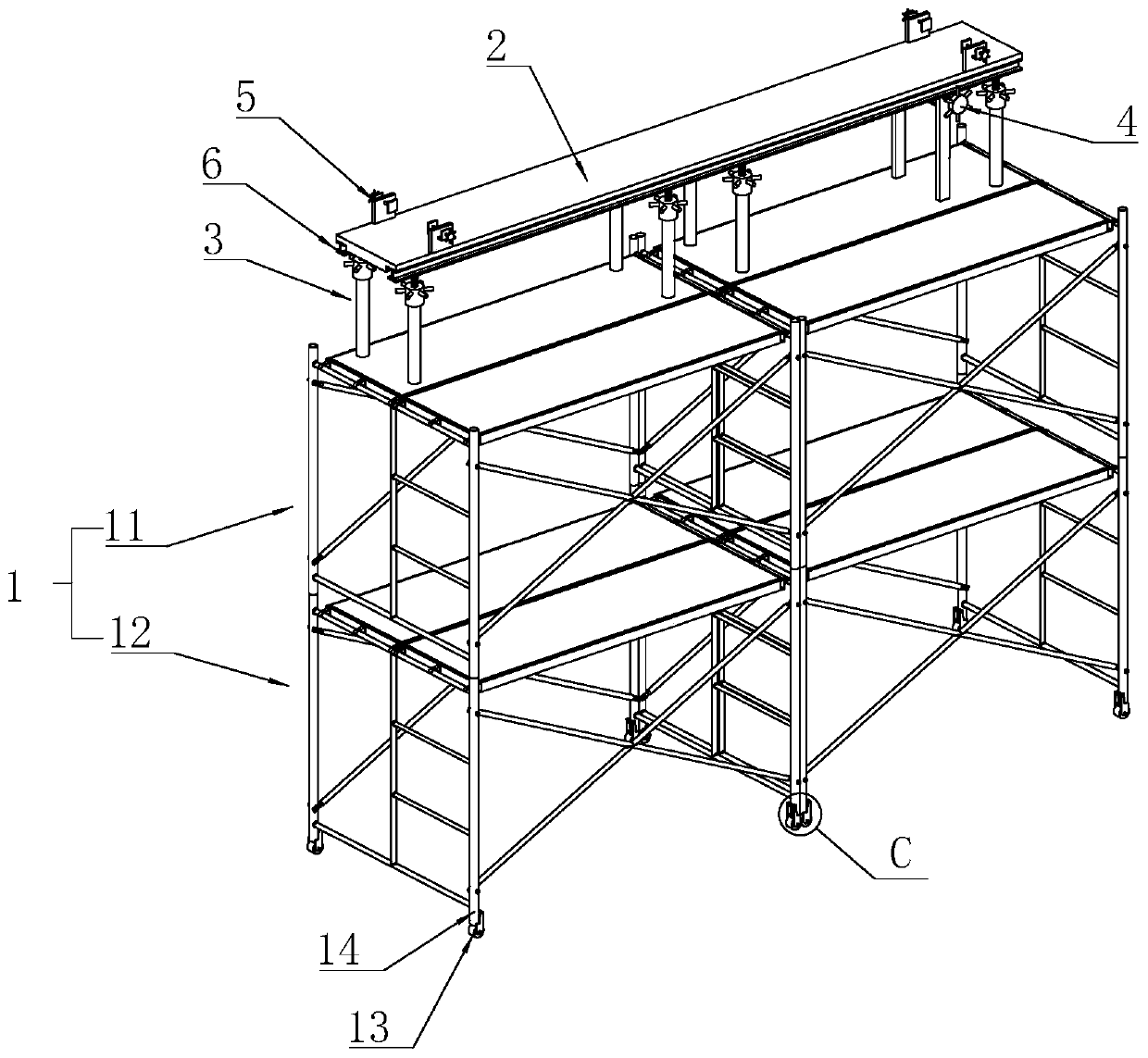

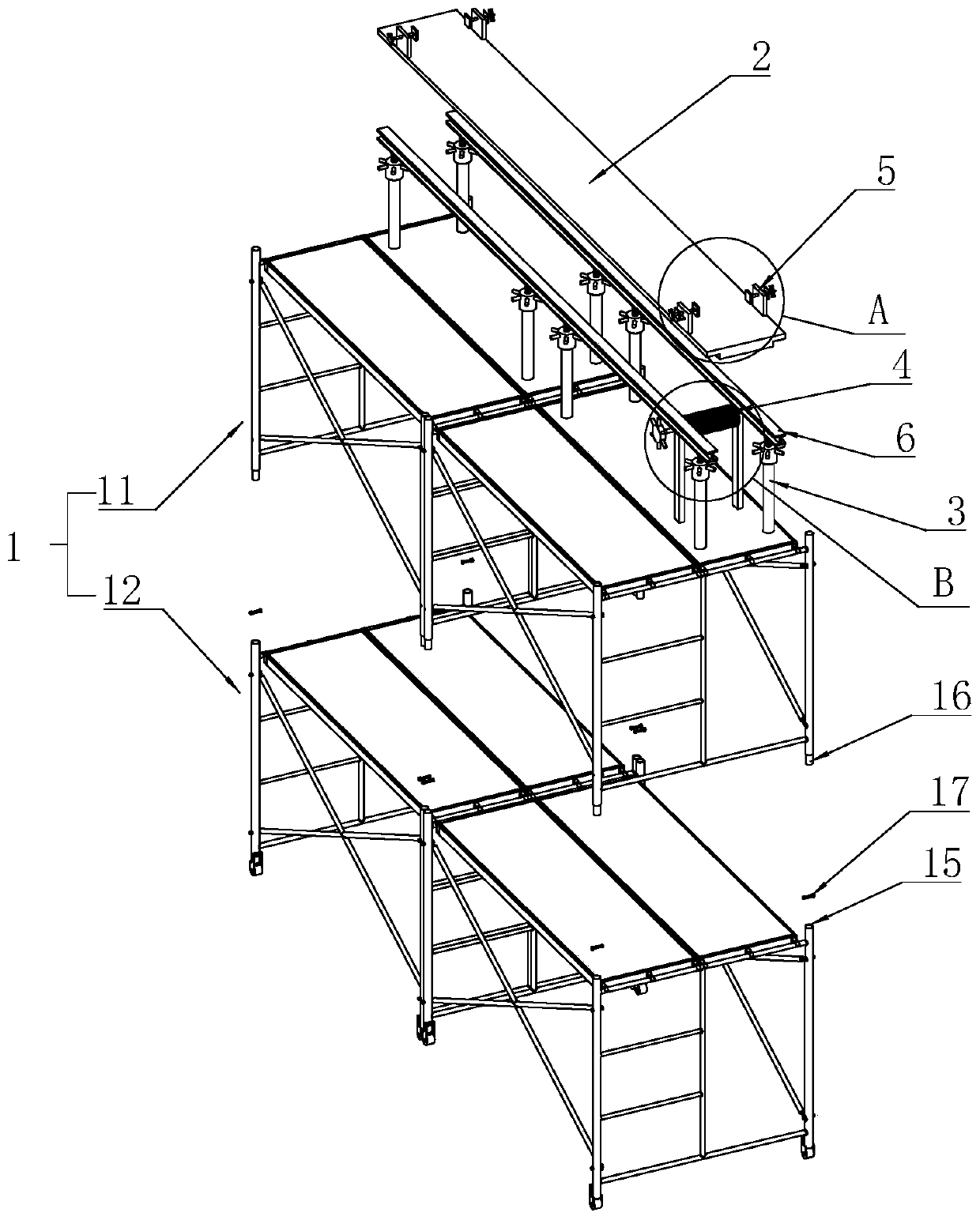

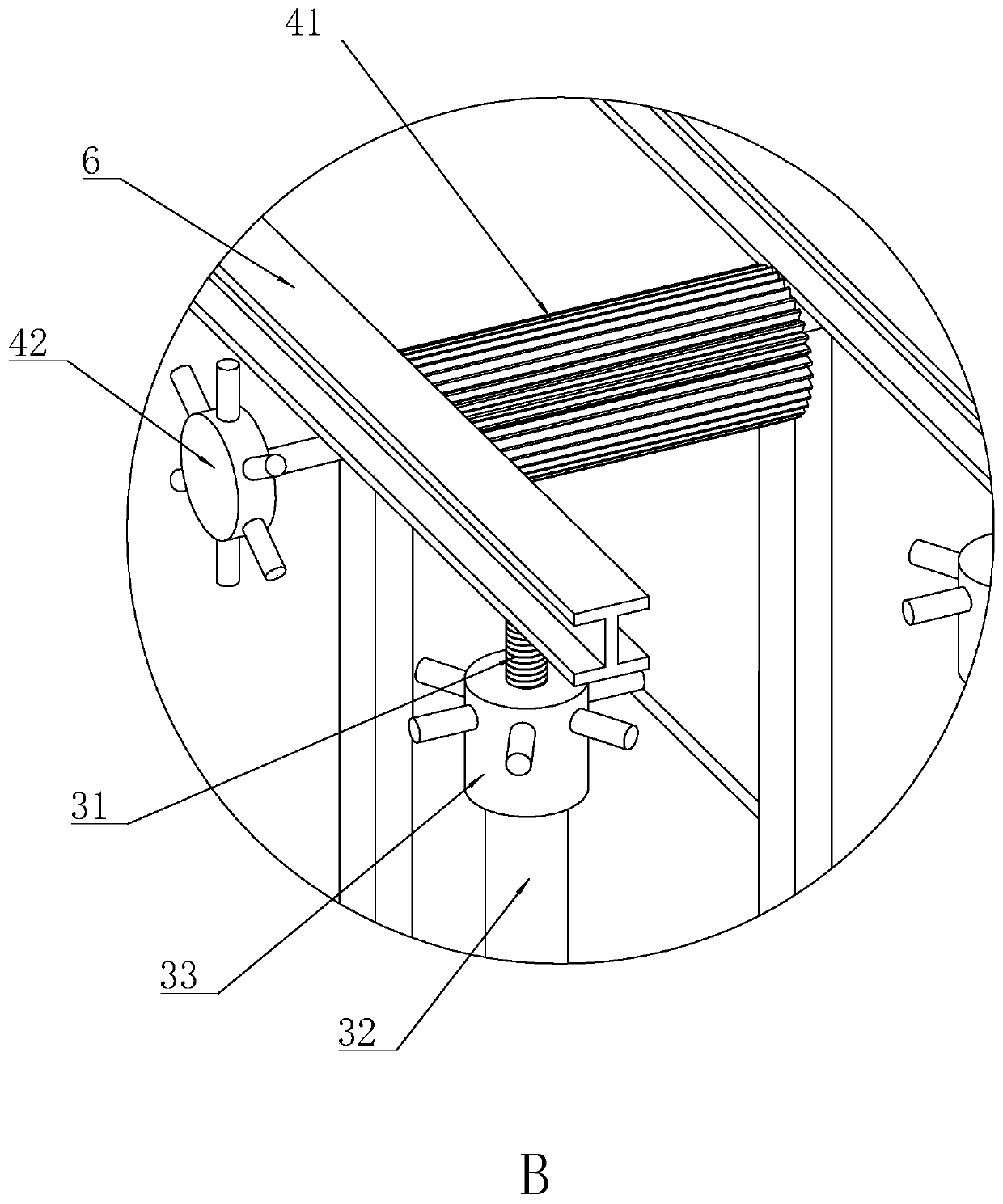

[0048] Embodiment 1: A kind of floor beam mounting bracket, such as figure 1 and figure 2 As shown, it includes a frame body 1, a beam 6, a horizontal adjustment plate 2, a height adjustment mechanism 3, a horizontal adjustment mechanism 4, and a vertical adjustment mechanism 5; wherein there are two beams 6, which are horizontally erected above the frame body 1; height adjustment The mechanism 3 is supported between the frame body 1 and the beam 6 . The horizontal adjustment plate 2 is T-shaped, and the protruding part below it is relatively short. The horizontal adjustment plate 2 is slidably erected on two beams 6, and the lower protrusion is located between the two beams 6 to limit; the horizontal adjustment mechanism 4 is located on the horizontal The bottom of the adjusting plate 2 drives the horizontal adjusting plate 2 to move along the length direction of the beam 6, which is the horizontal direction referred to in this solution. The vertical adjustment mechanism 5...

Embodiment 2

[0054] Embodiment 2: A construction method for using a floor beam mounting bracket, comprising the following steps:

[0055] Step S1 Move the lower frame 12 to the position where the floor beam needs to be installed, turn over the wheel part 13, so that the supporting part 14 of the lower frame 12 touches the ground;

[0056] Step S2 Fix and build one or more upper shelves 11 to a suitable height, and assemble the beam 6 on it, wherein the horizontal adjustment plate 2, the height adjustment mechanism 3, the vertical adjustment mechanism 5, and the height adjustment mechanism 3 mounted on the beam 6 are first Has been assembled on the beam 6;

[0057] Step S3 The tower crane lifts the floor beam to be installed in place and places it on the horizontal adjustment plate 2;

[0058] Step S4 Use the vertical adjustment mechanism 5 to adjust the angle of the floor beam and the position in the width direction of the beam 6;

[0059] Step S5 Utilizes the horizontal adjustment mecha...

Embodiment 3

[0063] Embodiment 3: as Figure 7 As shown, the difference from Embodiment 1 is that the horizontal adjustment plate 2 is respectively provided with a horizontal adjustment mechanism 4 and a reset mechanism 7 on both sides of the width direction at the same length position; The second vertical plate 71 on the plate 2, the spring 72 fixed on the second vertical plate 71 and facing the horizontal adjustment mechanism 4, and the baffle plate 74 fixed on the end of the spring 72, wherein at least one sliding plate is fixed on the inner side of the baffle plate 74 Move through the reset rod 73 of the second vertical plate 71.

[0064] When the bracket is installed and built, setting the horizontal adjustment plate 2 on one side of the bracket in the width direction can reduce the materials for construction, but at this time it also means that only the vertical adjustment mechanism 5 on one side is easy to operate; the spring 72 is used The reset structure can be reversely offset w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com