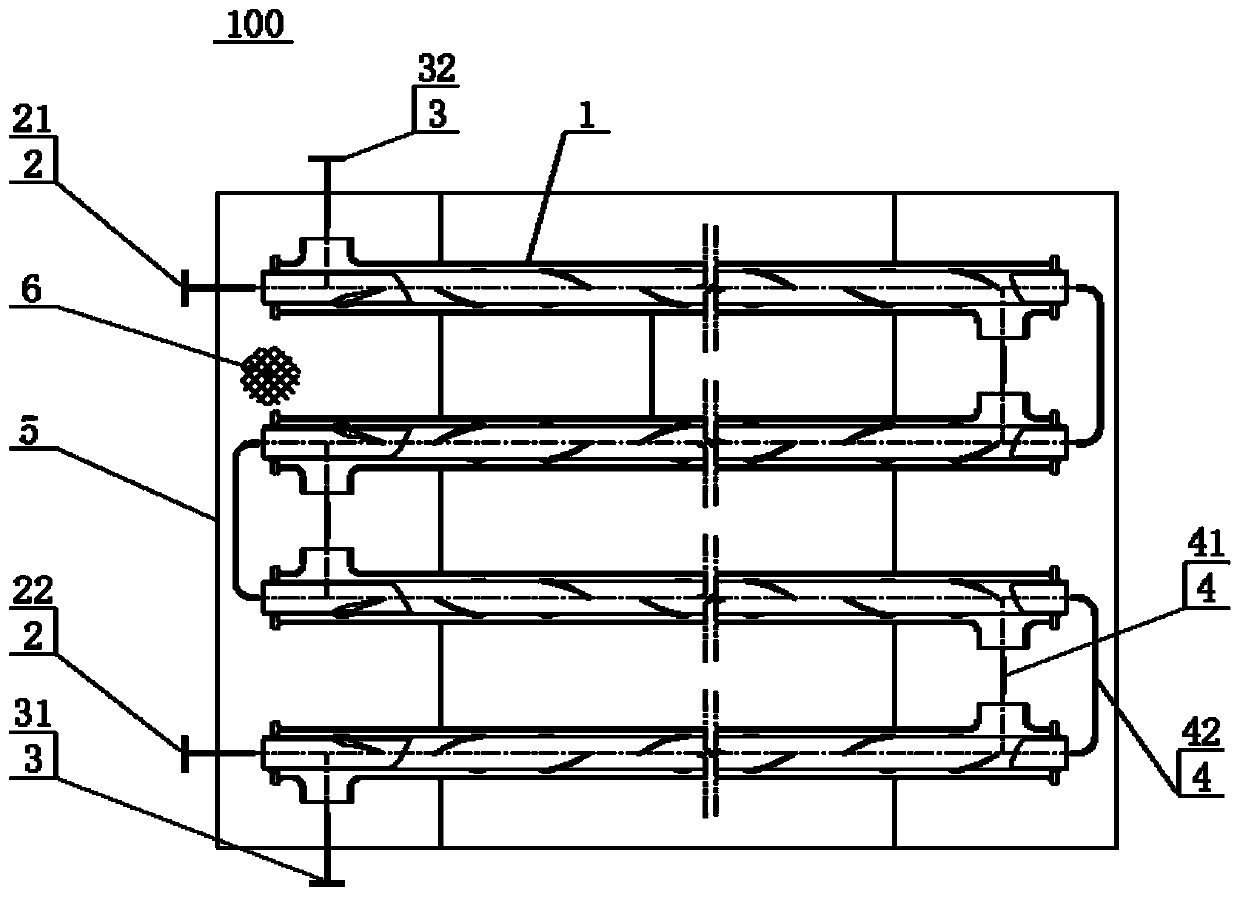

Sleeve-type heat exchange unit and non-clogging penetration mixed cyclone high-efficiency sleeve-type heat exchanger

A heat exchange unit, sleeve type technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of high pumping power consumption, decreased heat exchange performance, and blocked heat exchange performance. , to achieve the effect of eliminating blockage of heat exchange runners, reducing transmission power consumption, and stable and efficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

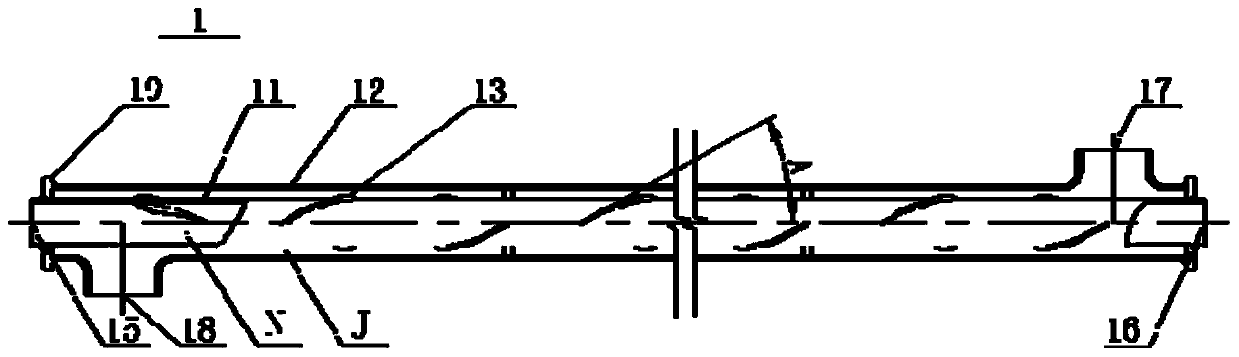

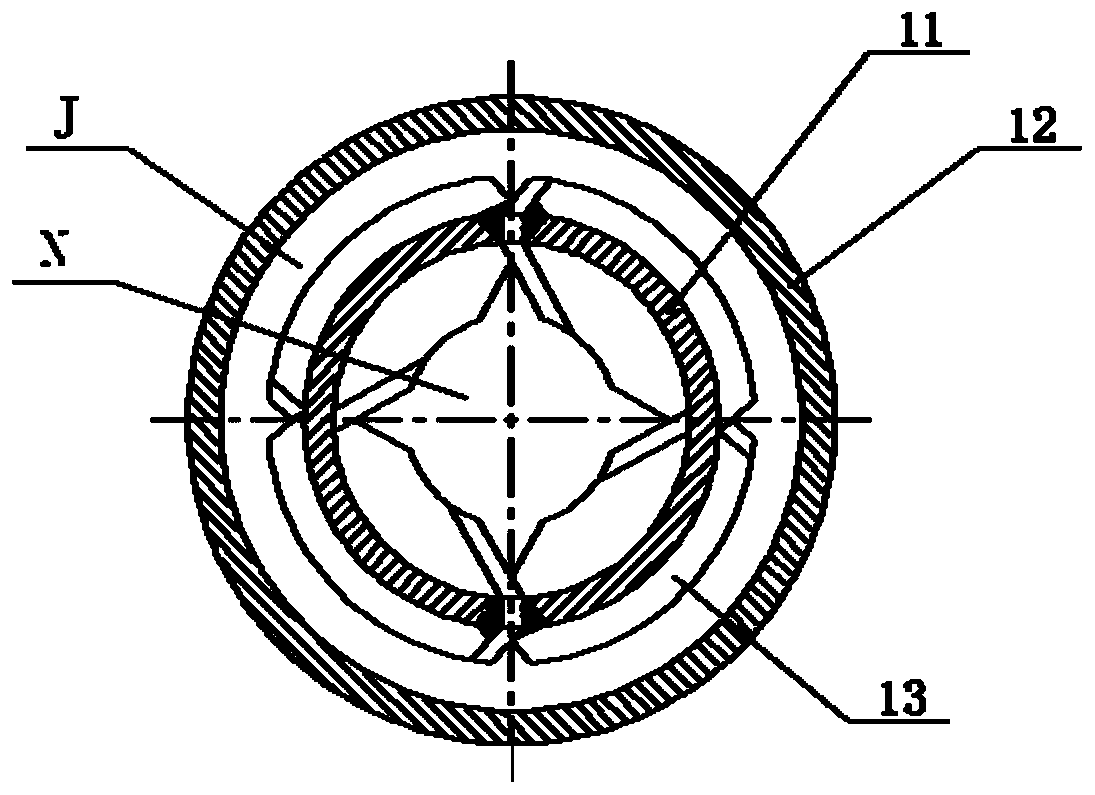

[0067] Example 1: If Figure 4 As shown, the oblique reinforcement 13 is formed into a twisted plate structure with a helix angle of 30°, the ratio of the radial dimension of the oblique reinforcement 13 protruding into the outer cavity J to the thickness of the outer cavity J is 0.4, and the oblique reinforcement The ratio of the radial dimension of the part of 13 protruding into the inner cavity N to the inner diameter of the inner tube is 0.3, and the chamfering angle of the oblique reinforcement 13 is 30°.

example 2

[0068] Example 2: If Figure 9-Figure 11 As shown, the oblique reinforcement 13 is formed into a flat plate structure with an inclination angle of 45°. The ratio of the radial dimension of the oblique reinforcement 13 protruding into the outer cavity J to the thickness of the outer cavity J is 0.5. The oblique reinforcement 13 The ratio of the radial dimension of the portion protruding into the inner cavity N to the inner diameter of the inner tube is 0.4, and the chamfering angle of the oblique reinforcement 13 is 30°.

example 3

[0069] Example 3: If Figure 12 , Figure 13 As shown, the oblique reinforcement 13 is formed into a flat plate structure with an inclination angle of 30°, the ratio of the radial dimension of the oblique reinforcement 13 protruding into the outer cavity J to the thickness of the outer cavity J is 0.6, and the oblique reinforcement 13 The ratio of the radial dimension of the portion protruding into the inner cavity N to the inner diameter of the inner tube is 0.5, and the two ends of the oblique reinforcement 13 are rounded. The oblique reinforcement 13 in this example is an elliptical flat plate structure, which is a special form of flat plate structure with rounded corners.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com