Hydrogen embrittlement evaluation method

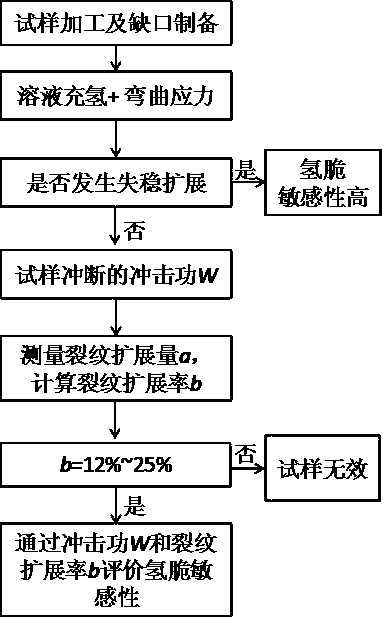

An evaluation method, the technology of hydrogen solution, is applied in the direction of testing the strength of materials by using a single impact force and testing the strength of materials by applying a stable bending force. It can solve problems such as abnormal fracture, escape, and excessive corrosion, and achieve strong versatility. The effect of a short trial period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] specific implementation plan

[0033] The present invention will be further described in detail below in conjunction with the examples.

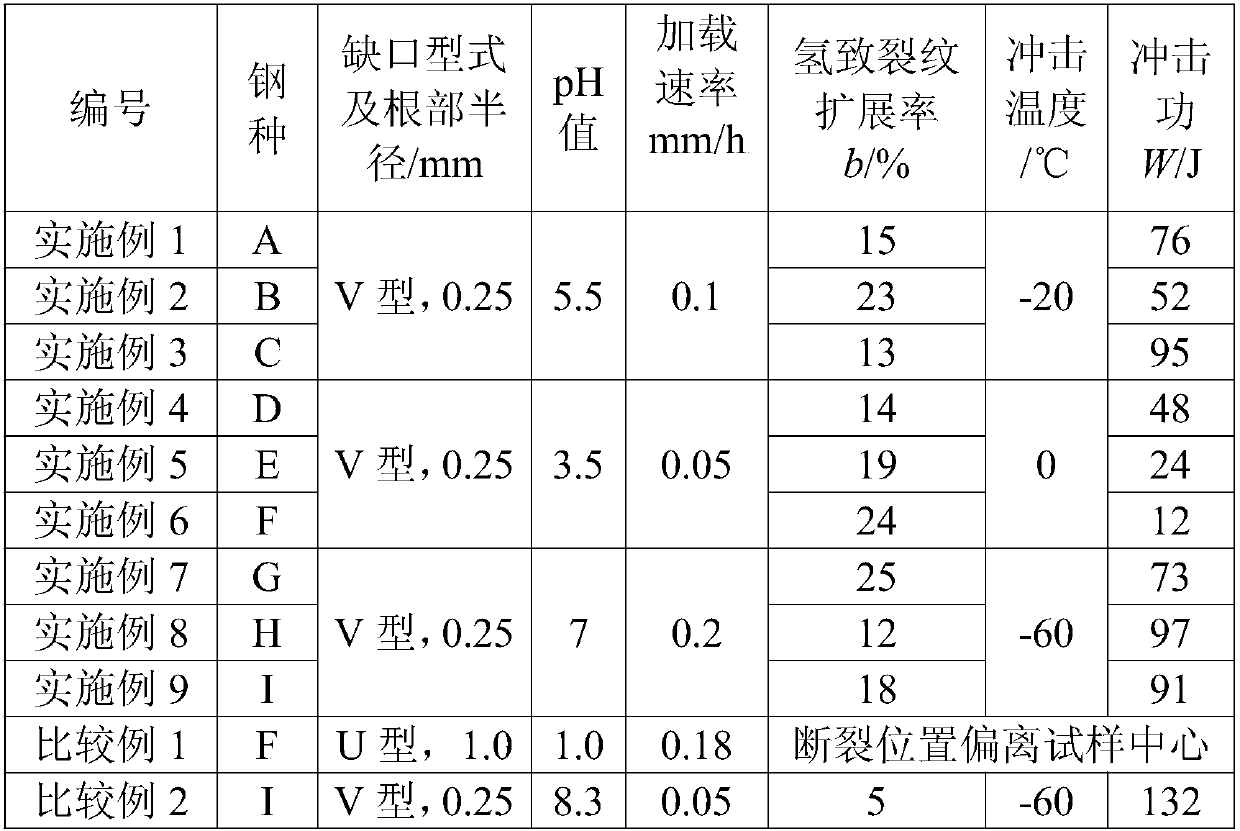

[0034] Table 1 is the test parameters and results of the hydrogen embrittlement evaluation of different materials using the method of the present invention, wherein A, B and C are pipeline steels of different strength levels, D, E and F are high-strength steels, and G, H and I are low-temperature steels. Steel, the sample size is 55mm (length) × 10mm (width) × 10mm (height).

[0035] The hydrogen charging solution is dilute sulfuric acid solution with different solubility, and 0.5g / L sodium thiosulfate is added to the solution at the same time, and the concentration of sulfuric acid solution is adjusted according to the pH value.

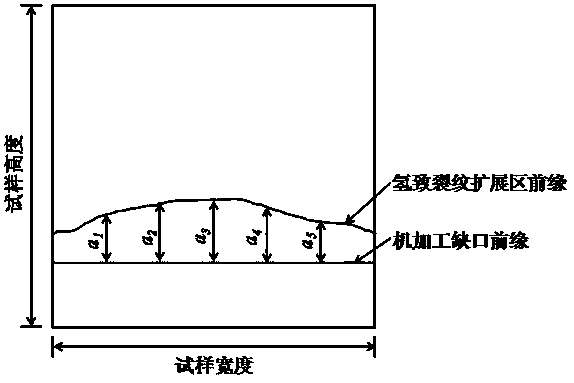

[0036] The application method of bending stress is the three-point bending method. While applying the stress, the load sensor and the displacement sensor are used to automatically record the load and displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com