Electric heating boiled water bottle

A water bottle and electric heating technology, which is applied to water boiling utensils, cooking utensils, household utensils, etc., can solve the problems of reducing the volume of the inner tank, endangering human health, and precipitation of plasticizers, reducing electrical failures and having a novel appearance. Beautiful, takes up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings:

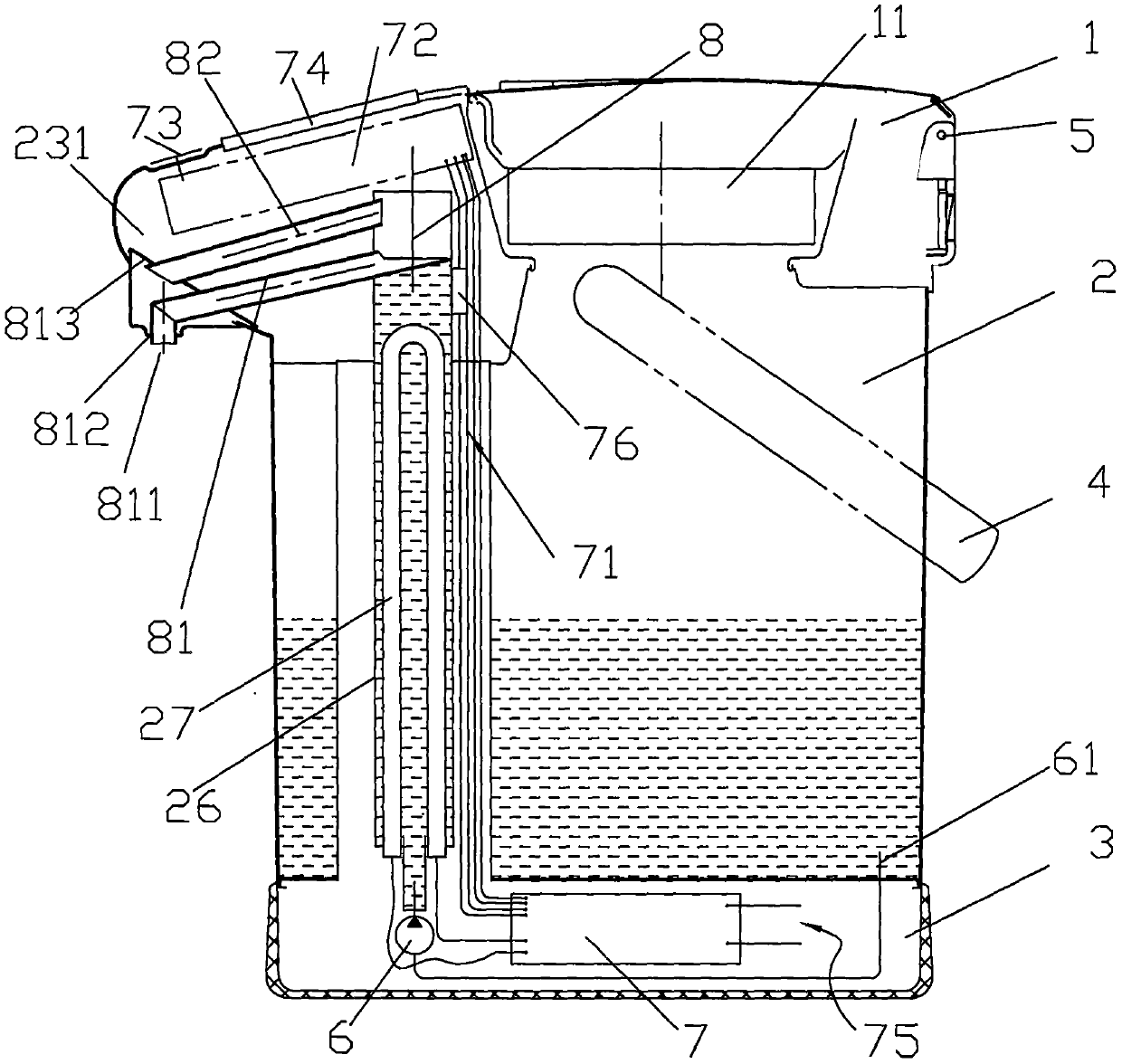

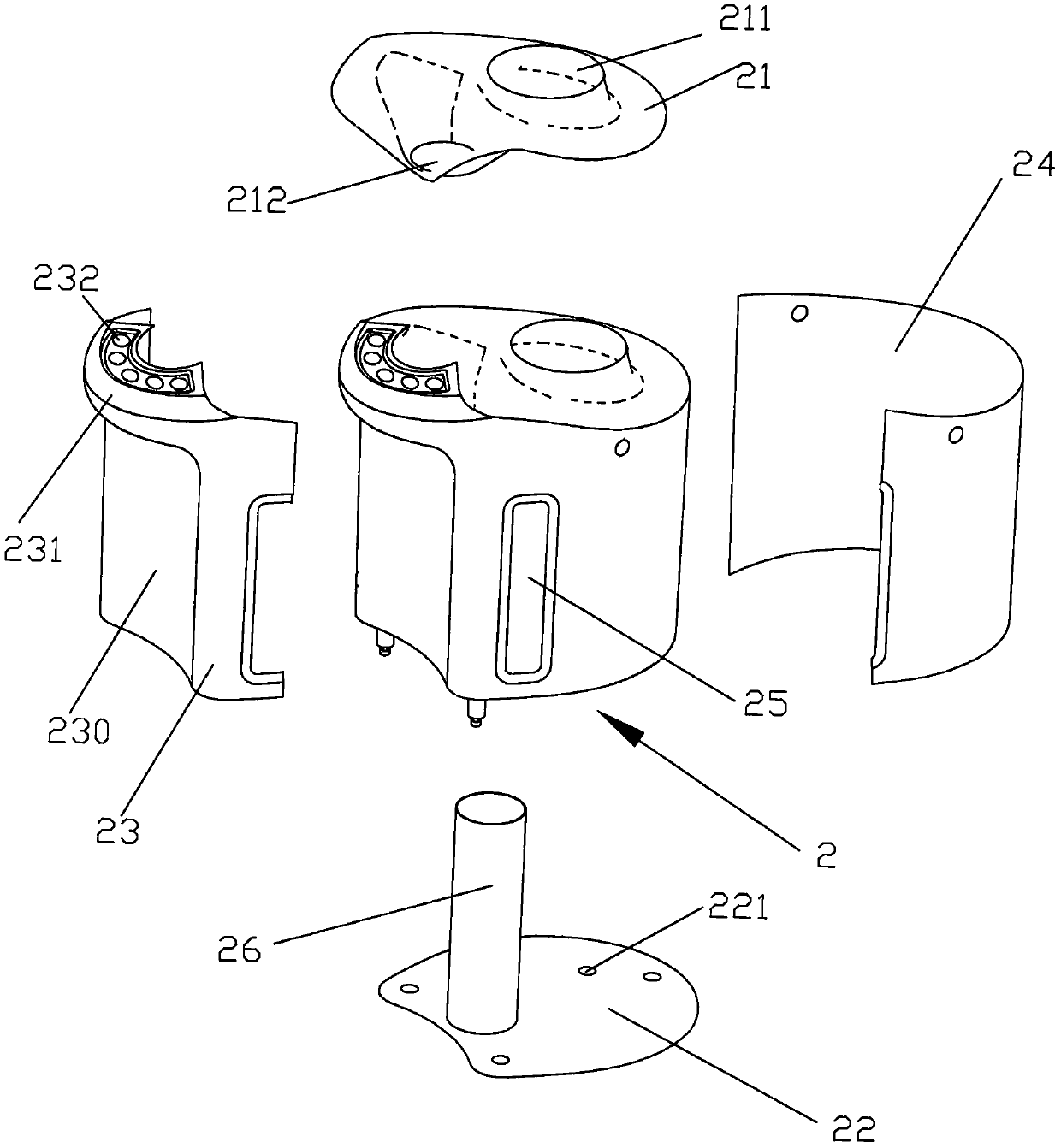

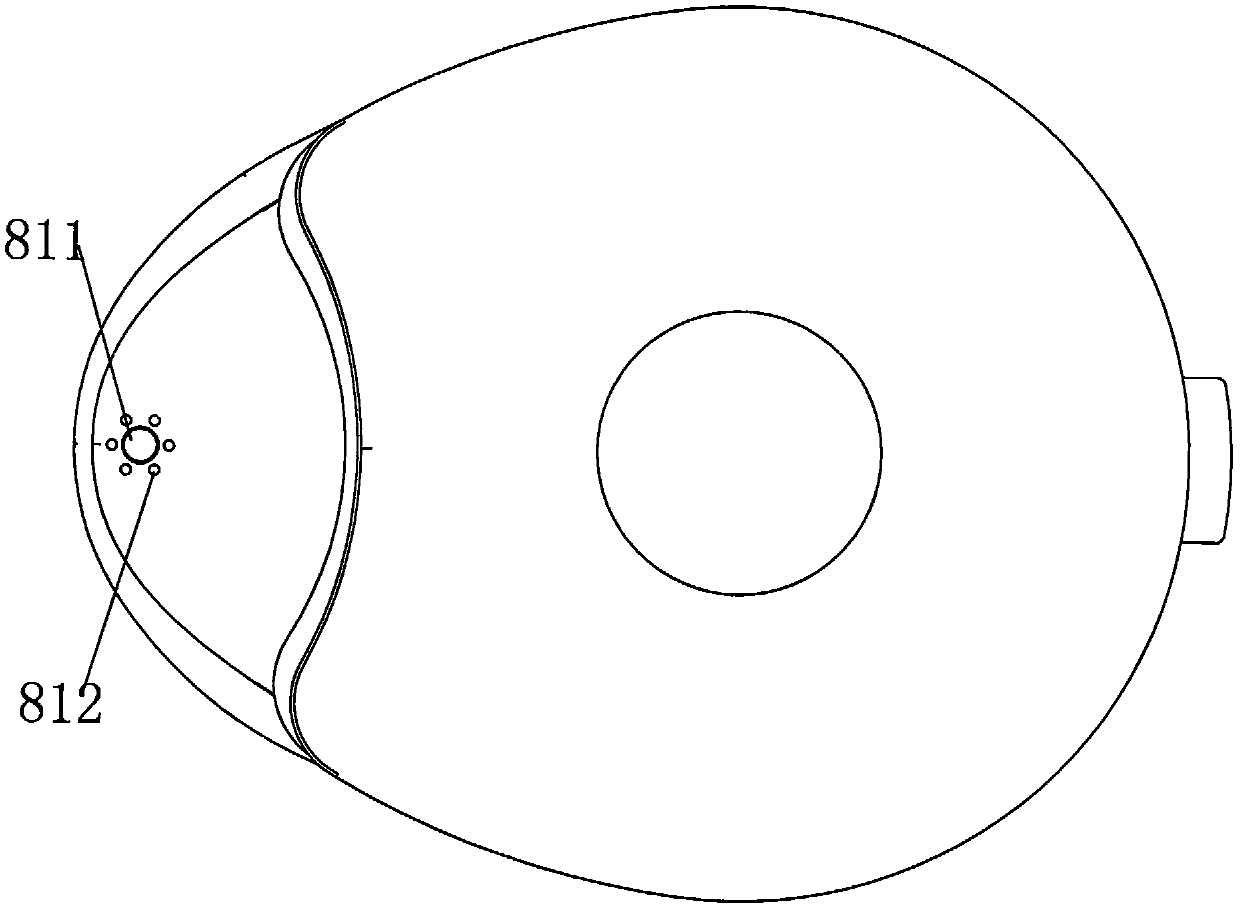

[0016] Such as figure 1 An electric heating water bottle shown in the embodiment, the rear end of the plastic upper cover 1 is hinged with the stainless steel bottle body 2 through the hinge shaft 5, so that the plastic upper cover can be turned up to add water; the front surface of the upper cover is equipped with a display screen 74, and the lower part There is a circuit board 72 and a bottle stopper 11 matched with the water filling port of the bottle body. The bottom periphery of the plastic upper cover 1 is in close contact with the upper edge of the stainless steel bottle body 2, and the bottom of the stainless steel bottle body 2 is fixedly connected with the base 3. The top of the stainless steel bottle body 2 is equipped with a handle 4. At least a micro-water pump 6 and a controller 7 are housed in the base 3, and the controller 7 is respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com