Constant tension control system based on fuzzy PID (Proportion Integration Differentiation)

A control system and constant tension technology, applied in the field of machinery, can solve the problem that the system cannot obtain the control effect, and achieve the effect of improving the control effect, good adaptability and fast dynamic response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

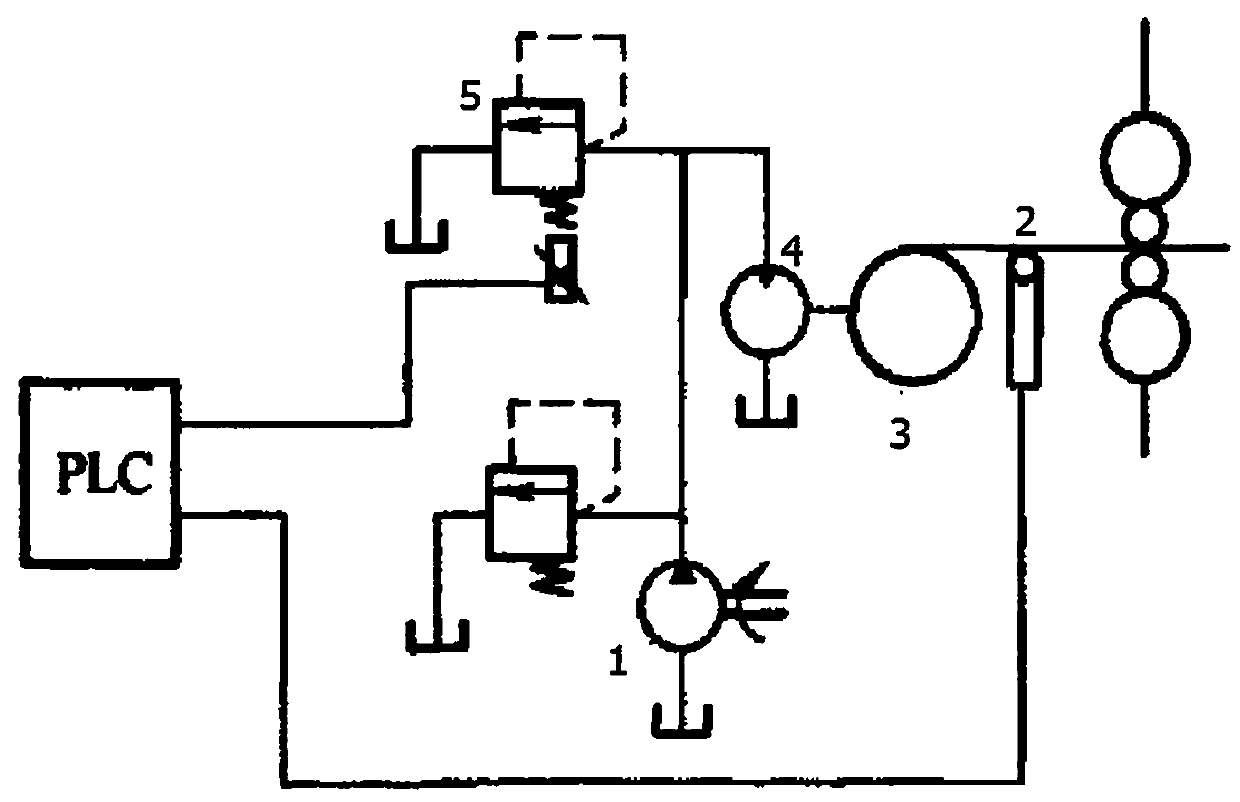

[0013] Such as figure 1 , The control system is mainly composed of a variable pump, a flow control valve, a proportional flow control valve, a hydraulic motor, a tensiometer, and a programmable controller. To keep the tension constant, the ratio of the pressure difference between the oil inlet and outlet of the hydraulic motor to the radius of the reel should be kept constant, and the oil return pressure of the hydraulic motor is equal to zero, so the strip can be accurately controlled only by controlling the oil inlet pressure of the motor. The magnitude of the tension, so that the control tension F is always maintained at a constant value. The tension of the rolled strip is checked by a tension sensor to detect the tension of the strip. And the feedback signal of the tension sensor is sent to the PLC, so that the control system constitutes a closed-loop control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com