Robot joint motor parameter identification and control parameter self-tuning method

A technology for robot joints and control parameters, applied in motor generator control, motor control, AC motor control, etc., can solve the problems of high hardware requirements, large data volume, complex calculation, etc., and achieve the effect of high identification accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

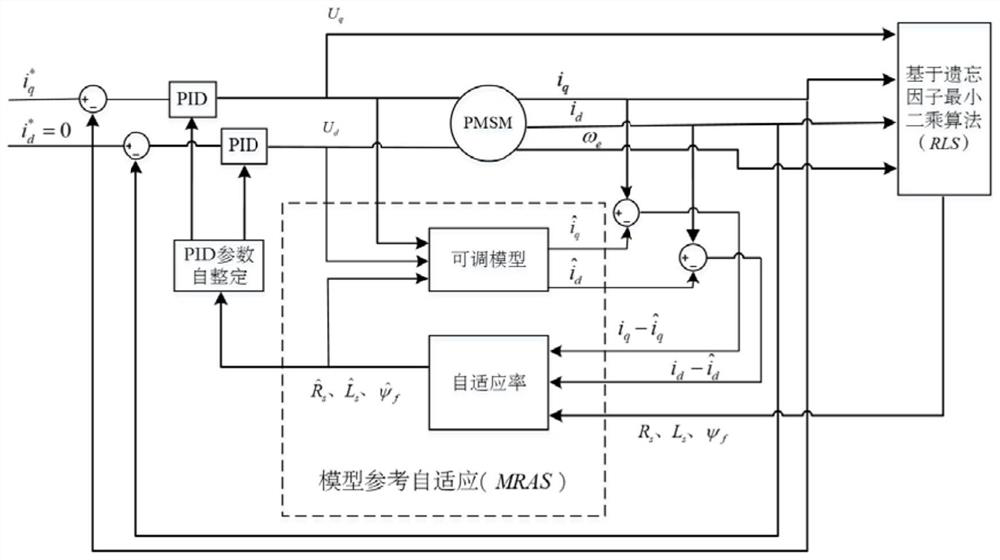

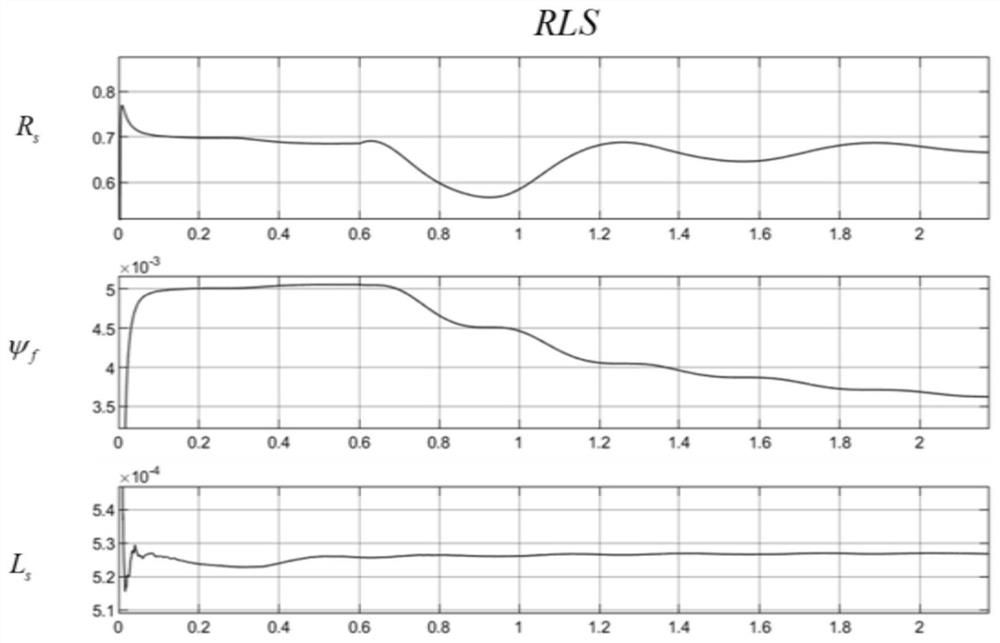

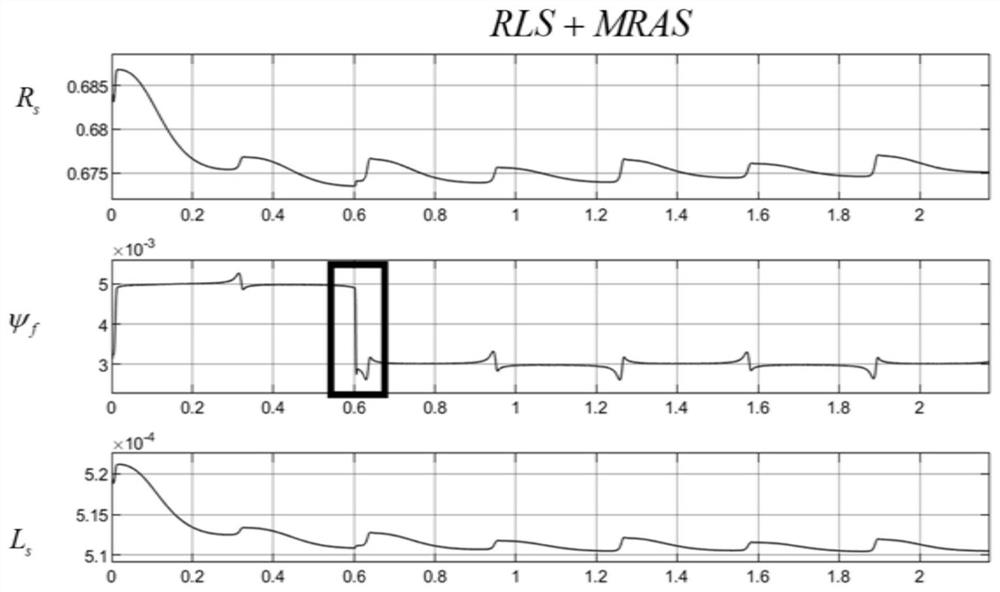

[0049] The present invention utilizes the least squares algorithm based on the forgetting factor to quickly identify the motor parameters as the initial value of the model reference self-adaptive algorithm to further accurately identify the motor parameters, and according to the identification parameters, online self-tuning of the motor control current loop PID parameters can achieve a better control effect .

[0050] Such as figure 1 As shown, the flowchart of the embodiment of the present invention has the following steps:

[0051] Step (1) Use the multi-loop PID servo control method and the motor vector control algorithm to control the movement of the joint motors of the robot, and collect the d-axis voltage u of the joint motors d , d-axis current i d , q-axis voltage u q , q-axis current i q and the motor rotor electrical angular velocity ω e .

[0052] Step (2) Utilize the recursive least squares algorithm based on the forgetting factor to identify joint motor resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com