Method for preparing lead carbonate from lead oxide waste

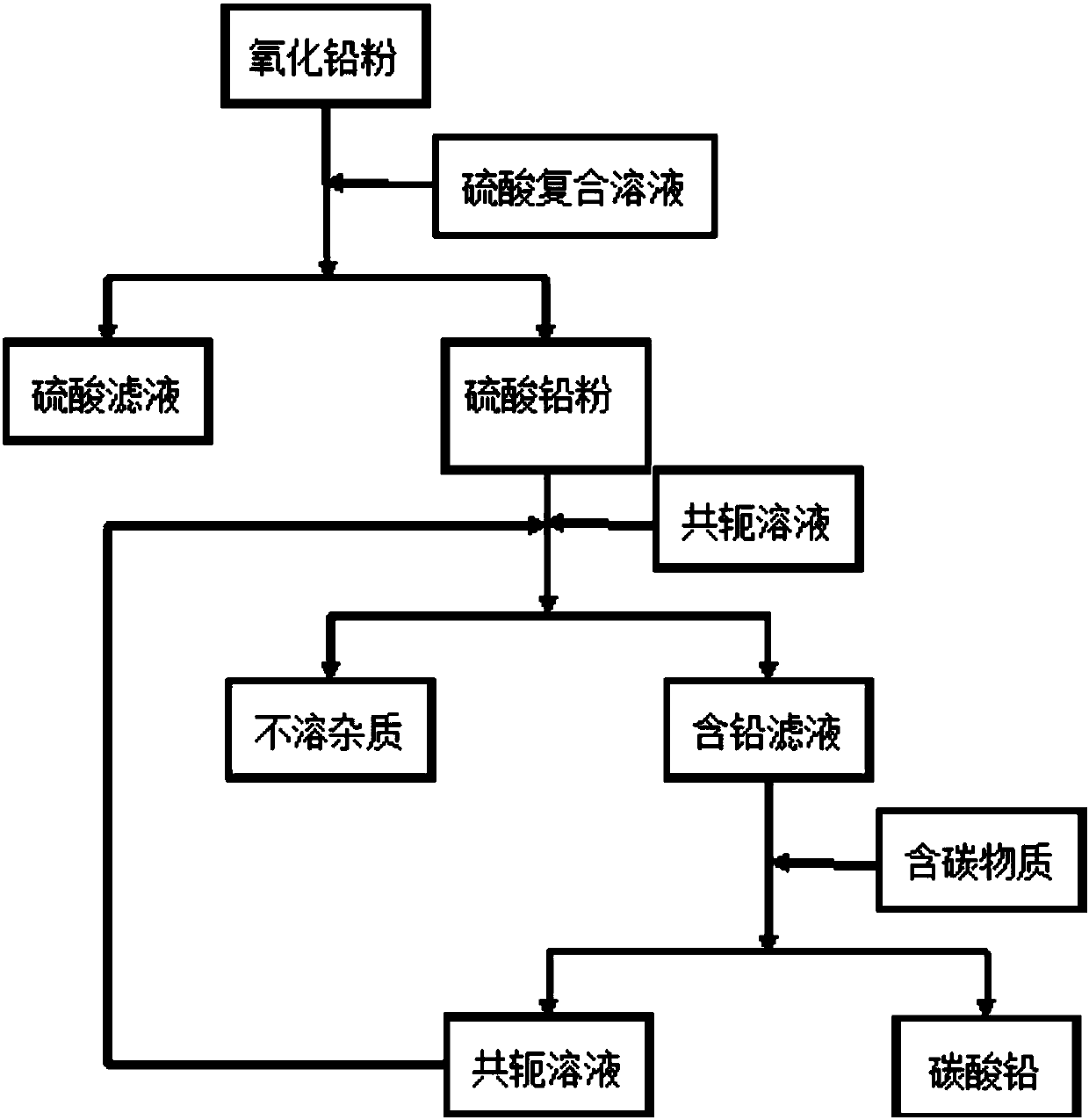

A lead oxide and lead carbonate technology is applied to the recovery of lead oxide-containing waste and the recovery of lead oxide waste, and can solve the problems of low purity of production products, low economic value of by-products, and high recovery costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Take lead oxide waste from Zhejiang Chaowei Battery Factory. The lead oxide waste was put into a muffle furnace and roasted at 600°C for 0.5h. The roasted lead paste whose main component is lead oxide after roasting is obtained, which is mainly 95% lead oxide (PbO) according to chemical determination, and the remaining amount is 3% lead sulfate and 2% clay. After processing as follows, the specific steps are:

[0057] (1) Vulcanization process: Add 1.00kg of roasted lead oxide waste into a 10L vulcanization reactor, add 6L of a composite solution of 5.0mol / L sulfuric acid+1.0mol / L acetic acid into the reactor, and control the reaction temperature at 70°C. The stirring rate was 300r / min, and the solid-liquid separation was carried out after continuous stirring for 3.0h to obtain 1.33kg of crude lead sulfate after acidification conversion and the mother liquor of compound acid. PbSO 4 The crude product was analyzed, wherein PbSO 4 The content is 99.5%, and the rest is...

Embodiment 2

[0062]The waste valve-regulated sealed lead-acid batteries with commercially available specifications of 12V and 7Ah were crushed and separated by conventional methods to obtain lead paste. The separated lead paste was put into a muffle furnace and baked at 600° C. for 1 h. A roasted lead paste whose main components are lead oxide and lead sulfate after roasting is obtained. The converted lead paste is analyzed by traditional chemical titration to obtain 40.2% of lead sulfate, 59.4% of lead oxide and 0.4% of other impurities.

[0063] Proceed as follows, the specific steps are:

[0064] (1) Vulcanization process: Add 1.00kg of pretreated converted lead paste into a 10L vulcanization reaction kettle, add 6L of a composite solution of 3.0mol / L sulfuric acid + 1.0mol / L acetic acid into the vulcanization reaction kettle, and control the reaction temperature at 80°C , the stirring speed is 300r / min, after continuous stirring for 3.0h, the solid-liquid separation is carried out, a...

Embodiment 3

[0069] Take lead oxide waste from Zhejiang Huitong Power Supply Company. The lead oxide waste was put into a muffle furnace and roasted at 600°C for 0.5h. The calcined lead paste whose main components are lead oxide and lead sulfate after roasting is obtained, which is mainly 95% lead oxide (PbO) according to chemical determination, and the remainder is lead sulfate and clay.

[0070] The recovery concrete steps of this lead oxide waste material are:

[0071] (1) Vulcanization process: Add 1.00kg of roasted lead oxide waste into a 10L vulcanization reactor, add 6L of a composite solution of 5.0mol / L sulfuric acid+1.0mol / L acetic acid into the reactor, and control the reaction temperature at 70°C. The stirring rate was 300r / min, and the solid-liquid separation was carried out after continuous stirring for 3.0h to obtain 1.33kg of crude lead sulfate after acidification conversion and the mother liquor of compound acid. PbSO 4 The crude product was analyzed, wherein PbSO 4 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com