Process for producing basic lead carbonate

A lead carbonate and process technology, applied in the field of non-ferrous metal recycling process, can solve problems such as waste of resources, environmental pollution, economic loss, etc., and achieve the effects of saving resources, optimizing processes, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

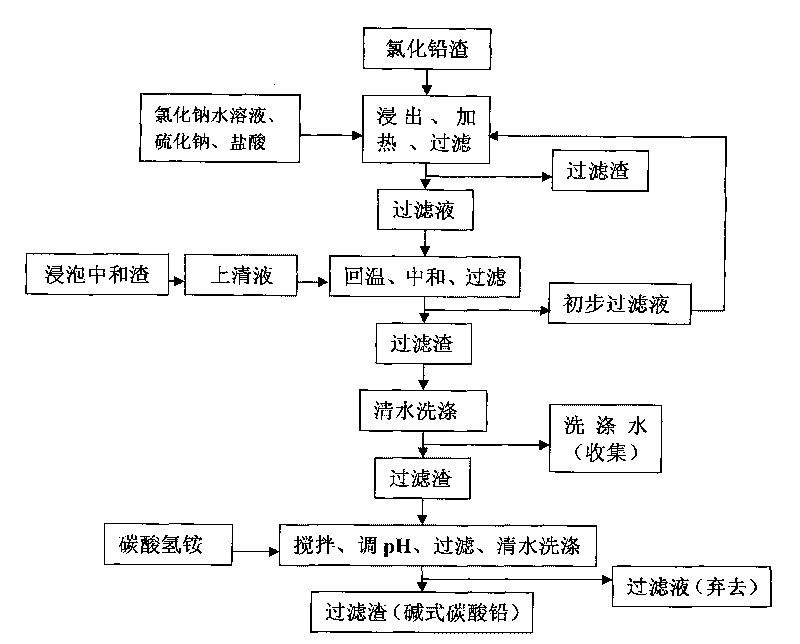

[0036] Such as figure 1 As shown, the "redundant slag" of bismuth refined by fire method is lead chloride slag (PbCl 2 ), neutralization slag (NaOH) as raw material, the technological process of producing low-impurity basic lead carbonate, the main steps include:

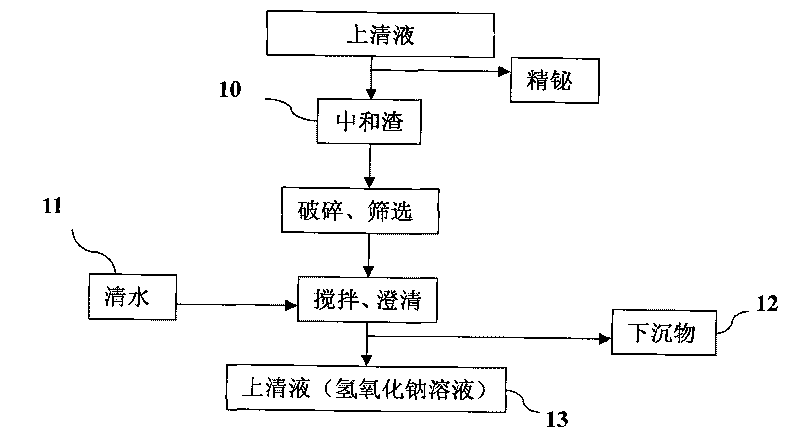

[0037] (1) Process of soaking and neutralizing slag to obtain sodium hydroxide solution

[0038] Such as figure 2 As shown, after the neutralization slag 10 is crushed, it is added to the immersion tank filled with clean water 11, the agitator is turned on, soaked for 1-2 hours, clarified, and the supernatant (sodium hydroxide solution) 13 is stored for use. The sinker 12 is dried and directly returned to the refining pot for smelting.

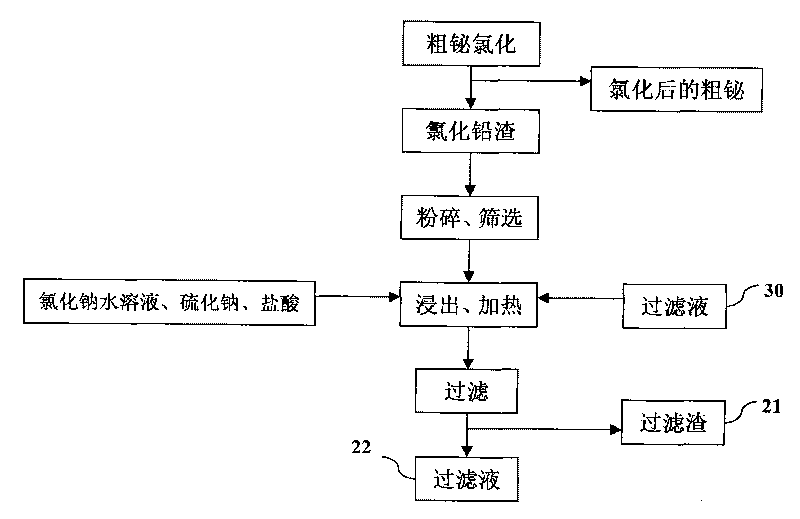

[0039] (2) Leaching lead chloride slag, filtration process

[0040] Such as image 3 As shown, the filtrate 30, the lead chloride slag crushed to about 200 mesh are fed into the reaction tank, and the sodium chloride concentration of the solution in the reaction tank is adjust...

Embodiment 2

[0047] Such as figure 1 As shown, the "redundant slag" of bismuth refined by fire method is lead chloride slag (PbCl 2 ), neutralization slag (NaOH) as raw material, the technological process of producing low-impurity basic lead carbonate, the main steps include:

[0048] (1) Process of soaking and neutralizing slag to obtain sodium hydroxide solution

[0049] Such as figure 2 As shown, after the neutralization slag 10 is crushed, it is added to the immersion tank equipped with clear water 11, the agitator is turned on, soaked for 1.5 hours, clarified, and the supernatant (sodium hydroxide solution) 13 is stored for use. The sinker 12 is dried and directly returned to the refining pot for smelting.

[0050] (2) Leaching lead chloride slag, filtration process

[0051] Such as image 3 As shown, the filtrate 30, the lead chloride slag crushed to about 200 meshes are fed into the reaction tank, and the sodium chloride concentration of the solution in the reaction tank is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com